Hi I'm was looking to upgrade my tool post to a quick change style for my Standard Modern 13 inch 2000 Series lathe. I am thinking to get one of the cheaper knock ones. Which would be either a wedge style Aloris BXA or a 40 position multifix style. Which the multifix style I am more so leaning towards but as for the size of one to order I am a bit confused.

Does any one have a 40 position quick change on there Standard modern lathe & have pictures & know which size to order?

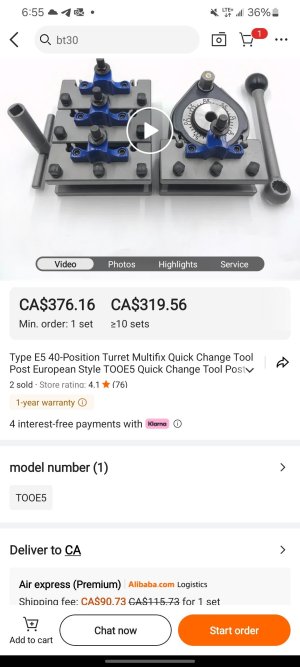

I was thinking of ordering from alibaba.com they seem to have good prices.

Does any one have a 40 position quick change on there Standard modern lathe & have pictures & know which size to order?

I was thinking of ordering from alibaba.com they seem to have good prices.