slow-poke

Ultra Member

I'm looking for a splined coupler set, a bit like a PTO shaft. I'm fairly flexible on tooth count, anything say 7 teeth and up and 1/2-1"1-1/2" diameter. Rigid straight steel, no universal.

I want to fit this between the quill handle and quill shaft on my mill so I can easily change the angle of the handle without tools. I'm looking for something either AkiExpress cheap or readily available at Princess Auto etc.

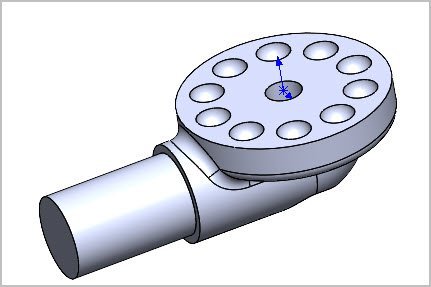

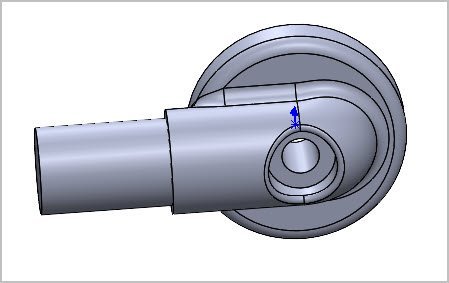

Something like this, except I need both halves.

My google searches are turning up everything but what I'm looking for.

I want to fit this between the quill handle and quill shaft on my mill so I can easily change the angle of the handle without tools. I'm looking for something either AkiExpress cheap or readily available at Princess Auto etc.

Something like this, except I need both halves.

My google searches are turning up everything but what I'm looking for.