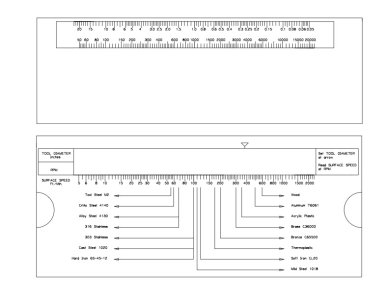

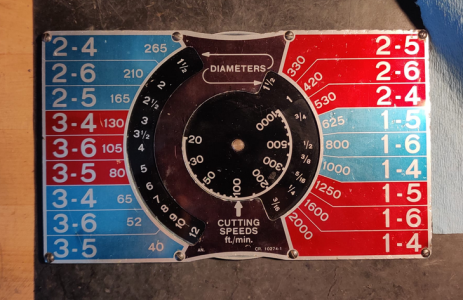

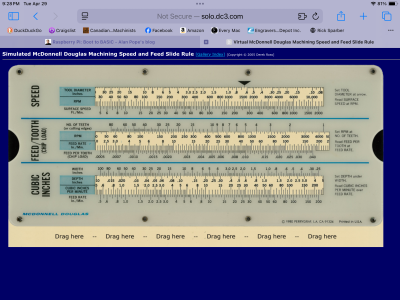

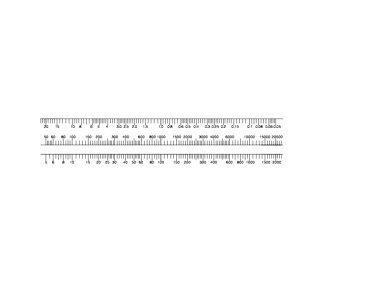

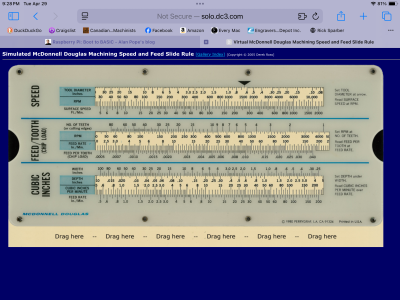

Saw this Feed and Speed slide rule and decided I want to make one. Probably will be engraved aluminum sheet. I haven't worked out the details yet but I've cobbled up the scales. The beauty of a slide rule is it always works, never needs recharging, and can provide an answer starting from any two variables.

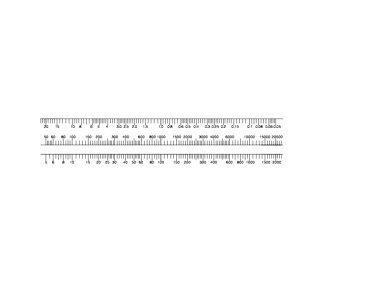

I'm only making the Speed section, all my machines are manual so chip load and cubic inch calculations are irrelevant.

Wild ass thought, engrave the side rule scales on the back of a cheap brass caliper?

DXF file at https://www.dropbox.com/scl/fi/d241...ey=m5eq9w9q4n9nspjyn89ro73sz&st=1rsrywj5&dl=0

I'm picturing a slide rule with a chart of materials vs. typical SFM values. My electronic SFM calculators work, but this will be cooler and doesn't need a battery.

I'm only making the Speed section, all my machines are manual so chip load and cubic inch calculations are irrelevant.

Wild ass thought, engrave the side rule scales on the back of a cheap brass caliper?

DXF file at https://www.dropbox.com/scl/fi/d241...ey=m5eq9w9q4n9nspjyn89ro73sz&st=1rsrywj5&dl=0

I'm picturing a slide rule with a chart of materials vs. typical SFM values. My electronic SFM calculators work, but this will be cooler and doesn't need a battery.