-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So tell me which mill vise to buy??

- Thread starter GummyMonster

- Start date

GummyMonster

Ken

All this help is awesome and very appreciated.

Decided I'm going to sign up as a premium member as I get a LOT of great advice here, and I don't mind helping a little to keep it up and running.

Back to the vise issue. Yes, I am going to go with a grinding vise. I'll probably buy 2-3 different ones for the price.

I should be able to improve them a little if needed as far as trueness and smoothness with a little tlc. I've done lots of this actually, buying inexpensive tools and such and improving them with a bit of hands on time.

Someone mentioned making more basic things to sell as a way to upgrade. That's exactly what I'm planning. There's lots of niche market items a person can make. Especially up here in canada, as well as northern Alberta. So many little things that can't or wont be shipped from the USA.

Ken

Decided I'm going to sign up as a premium member as I get a LOT of great advice here, and I don't mind helping a little to keep it up and running.

Back to the vise issue. Yes, I am going to go with a grinding vise. I'll probably buy 2-3 different ones for the price.

I should be able to improve them a little if needed as far as trueness and smoothness with a little tlc. I've done lots of this actually, buying inexpensive tools and such and improving them with a bit of hands on time.

Someone mentioned making more basic things to sell as a way to upgrade. That's exactly what I'm planning. There's lots of niche market items a person can make. Especially up here in canada, as well as northern Alberta. So many little things that can't or wont be shipped from the USA.

Ken

Someone on a another forum recently checked one of these happy vise (https://www.amazon.ca/dp/B07GZDP733?psc=1&smid=A34OE2ORYCIEHP&ref_=chk_typ_imgToDp) and posted a survey of it - squareness, parallel, etc. I can think of happier vices and his numbers seemed optimistic, but I just order the 3" version to check out.

I'll disagree with Dabbler on the grinding vise thing, but he strikes me as an experience chap so I respect his view on it. Me, I find using a grinding vise a PIA for grinding and I don;t think they have the clamping power of a milling vise. I endure it grinding becuase its probably less than 5% of the time that I'm using the vise, but imo it would really sub-optimal having to use a screwless everytime I want to use the mill.

Granted, my dislike is part because the ones I have are the common type with the pin holes.....the permanent pin and scallop style, e.g. Herman Schmidt, would less frustrating (but if you're buying a Herman Schmidt, cost isn't a big concern, so just buy the 4" Kurt).

The other fantastic vise the old D3, a 3" Kurt vise longer made. Came across one for $25 so I pounced on it.....just have to get a mill that size now . They are out there and come up on ebay

. They are out there and come up on ebay

I've got a couple of baby mills I'd thought of making a D2 for, but alas have pushed that back until at least lifetime #5

I'll disagree with Dabbler on the grinding vise thing, but he strikes me as an experience chap so I respect his view on it. Me, I find using a grinding vise a PIA for grinding and I don;t think they have the clamping power of a milling vise. I endure it grinding becuase its probably less than 5% of the time that I'm using the vise, but imo it would really sub-optimal having to use a screwless everytime I want to use the mill.

Granted, my dislike is part because the ones I have are the common type with the pin holes.....the permanent pin and scallop style, e.g. Herman Schmidt, would less frustrating (but if you're buying a Herman Schmidt, cost isn't a big concern, so just buy the 4" Kurt).

The other fantastic vise the old D3, a 3" Kurt vise longer made. Came across one for $25 so I pounced on it.....just have to get a mill that size now

I've got a couple of baby mills I'd thought of making a D2 for, but alas have pushed that back until at least lifetime #5

Several of the grinding vises from Offshore have the moveable pin, which allows adjustment without disassembly. I should have clarified that particular thing, as @Mcgyver says, the ones that require you to extract the pin and move it to adjust are a pain.

For grinding, only a light touch is required to correctly hold the item. any more and you can distort the vise jaws or the part. On my 3 grinding vises, they all use around a 12 pitch thread, so they hold with several hundreds of pounds of pressure, that's plenty for a tiny mill like that.

A grinding vise will never hold the pressures against a 3" face mill, but that machine is really only suitable for fly cutting for faces and 1/2" end mills and smaller.. Using larger mills will flex that machine and give you a bad cut anyway.

One can also repurpose a heavy drill press vise like the one below for a small mill like the OP's I am assuming the OP is on a low budget, as larger machines don't cost much more, but enough that economy is dictated.

For grinding, only a light touch is required to correctly hold the item. any more and you can distort the vise jaws or the part. On my 3 grinding vises, they all use around a 12 pitch thread, so they hold with several hundreds of pounds of pressure, that's plenty for a tiny mill like that.

A grinding vise will never hold the pressures against a 3" face mill, but that machine is really only suitable for fly cutting for faces and 1/2" end mills and smaller.. Using larger mills will flex that machine and give you a bad cut anyway.

One can also repurpose a heavy drill press vise like the one below for a small mill like the OP's I am assuming the OP is on a low budget, as larger machines don't cost much more, but enough that economy is dictated.

Last edited:

Just as a data point Accusize has a 4" for 246 CAD. It has a recess in the base as opposed to just through holes, so more forgiving in terms of side clamps. You will probably see this same vise elsewhere but just do the all-in shipping to your door. Accusize is primarily a redistributor of Chinese tooling, sometimes price competitive, sometimes less so. I think I have the smaller one of these, cant recall exactly. If its the one I'm thinking of needed a bit of TLC on the clamp mechanism. Kind of strange, they do precision grinding everywhere & then kind of shortcut the tactile thing you use every single time.

https://accusizetools.com/products/precision-screwless-vises?variant=35245860487322

Herman Schmidt, apparently thegold kryptonite standard. Maybe its the blueprint basis for clones. I've given up trying to find a used one. This little 1.5" gem a paltry +1000CAD <gulp> Makes Suburban tools look cheap. https://www.ebay.ca/itm/255079236772?hash=item3b63e844a4:g:jOIAAOSwItBhDBhR

https://accusizetools.com/products/precision-screwless-vises?variant=35245860487322

Herman Schmidt, apparently the

George

Member

Got me a 3 inch vice from eBay free shipping and it’s great looks ok on my mini mill 700x180 a bigger vice would be difficult to mount and be overkill, just saying if your not making parts for NASA why spend that much for a vice. Cheap Chinese mini mills are great but there no Bridgeport’s. My vice can break 4 times before it catches up with the price of a high end vice.

Just to give a perspective view the vice on the left is 4” and right is 3”. The 3” was $99 from eBay with free shipping. It came from Vancouver and only took 5 days to arrive, i also had a 6” vice in my shopping cart and a week later it was offered at a discount price, food for thought.

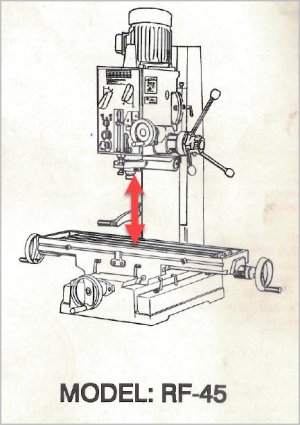

This is my Milling Machine, mine cost an Extra $50 to have the 700mm bed, the price shown is for the 500mm. Mine is the VL Model with MT 3.

https://wmtcnc.en.alibaba.com/produ...l?spm=a2700.shop_plgr.41413.23.3fa95eb06oD8lq

Just to give a perspective view the vice on the left is 4” and right is 3”. The 3” was $99 from eBay with free shipping. It came from Vancouver and only took 5 days to arrive, i also had a 6” vice in my shopping cart and a week later it was offered at a discount price, food for thought.

This is my Milling Machine, mine cost an Extra $50 to have the 700mm bed, the price shown is for the 500mm. Mine is the VL Model with MT 3.

https://wmtcnc.en.alibaba.com/produ...l?spm=a2700.shop_plgr.41413.23.3fa95eb06oD8lq

Attachments

Last edited:

This style of grinder vise has through holes vs a rail. I'm actually not sure if that doubles as hold down for pin style clamps. Or if clamping is reserved to the front & rear indentations. You might have to research this more. I prefer the continuous notch rail down the side for this reason but I might not have the full story.

View attachment 16633

The problem with end clamping is that it is hard to get it to line up with two T-slots. I've read that end clamping can also distort the vice.

I believe that these machinist vices are intended to be used with Pin Clamps.

@Dabbler calls these vises a grinding vise. And they are. However, I've also seen them called screwless vise, toolmakers vise, and machinists vise (my favorite term). I'm sure there are probably many nuances to define each one, but frankly, they all look the same to me. If you get a good one, you have a good one.

Note that the ones with the tightening screw on an angle have the same impact as a prismatic jaw you and I talked about off line. They pull the work down as they tighten.

The beauty of these vises is that they are typically very precise AND they can be used as an additional accessory with bigger mills if that ever happens.

I've seen them with nice adjusting systems that don't require pin removal to change the jaw gap. But these were typically more expensive.

Last but not least, both of mine have small notches (vertical and horizontal) for holding round stock.

I got both of mine at an auction so I didn't get Clamps with them. But if you do decide to get a new one, you should try to get it with hold down clamps designed to fit it.

Last edited:

I have the older Busy Bee CT129 version of this mill. I use a 5” Busy Bee CXVISE1, it’s the biggest that will fit on the table. It’s crap, but with a bit of fiddling I can get it true in all three planes within a couple of thou. The degree scale is useless. If I’m doing angular stuff I use a digital indicator, a bit chunk of square bar and some trig to get to the angle I need.

It’s so easy to get tied up with gear we forget it’s the machinist that makes the parts, not the machine.

A quote I ran across a few weeks ago:

Humans have always managed to produce tools and instruments that are more precise, accurate, and more sophisticated than the tools and instruments used to make them.

It’s so easy to get tied up with gear we forget it’s the machinist that makes the parts, not the machine.

A quote I ran across a few weeks ago:

Humans have always managed to produce tools and instruments that are more precise, accurate, and more sophisticated than the tools and instruments used to make them.

I believe that these machinist vices are intended to be used with Pin Clamps.

.

I believe they are supposed to be used with a mag chuck (just being a smartass)

I have a big and small mills, so have a want that is maybe not the same as everyone's. I'm going to use a small mill for small work, so I would like to a jaw height on 2" vise say 1/3 of that of a 6" vise. But with a grinding vise I get a jaw for a 2" vise that is likely the height as the 6" Kurt.

the Happy Vise arrived yesterday. I'm getting to old for happy vices, but you can have a happy vise for $100.

I'l try to survey the Happy Vice this weekend and report back, but its a busy shop weekend as it is

I believe they are supposed to be used with a mag chuck (just being a smartass)

Well why not? I've used mine in the Jaws of my much bigger vise whenever I needed to hold something small or something round. It looks goofy, but it works!

I guess that makes me a smartass too! 8)

Tom O

Ultra Member

Sounds exotic! So is it really made of cast iorn?I believe they are supposed to be used with a mag chuck (just being a smartass)

I have a big and small mills, so have a want that is maybe not the same as everyone's. I'm going to use a small mill for small work, so I would like to a jaw height on 2" vise say 1/3 of that of a 6" vise. But with a grinding vise I get a jaw for a 2" vise that is likely the height as the 6" Kurt.

the Happy Vise arrived yesterday. I'm getting to old for happy vices, but you can have a happy vise for $100.I think its going to be too high a profile for the little BCA mill, the angle lock mechanism eats up a lot of day light. On that attribute, the grinding vise is probably better. I still attached to the idea of making a low profile angle lock vise

I'l try to survey the Happy Vice this weekend and report back, but its a busy shop weekend as it is

Never heard of iorn - do they get that from goats? (sorry, couldn't help myself)

Based on the shape of the base, I'd say it has to be. It isn't a forging. But I don't think of that as exotic. I'd call it "run of the mill" (standard material) for big low-cost mill vises.

GummyMonster

Ken

I'm wondering if this is the same as the happybuy vise: better price - https://www.ebay.com/itm/154390589530

I'm wondering if this is the same as the happybuy vise: better price - https://www.ebay.com/itm/154390589530

I think so. It's seems everybody sells it so I'd guess some shop in Korea (or wherever) makes them for rebranding outfits all over the world.

Here is the happy buy 4" for 130 on amazon that includes the swivel,

And here is my 4" Grizzly.

I'd say they are the same......

FWIW, my grizzly has served me just fine on my big mill/drill. It has LOTS of room for a big vise.

Without the removable swivel, it's a nice compact and very strong vise for the price.

Edit - sorry, somehow I snagged the photo for the Griz 3". The 4" looks similar but more like the happy buy. The forum editor won't let me change the photo.....

GummyMonster

Ken

No worries about the pic. I found around 12 different vendors on ebay all selling the same 2-3 vise, either unbranded or with different names. I've decided I'm going to buy 2-3 different different styles off there, and I should end up with at least a couple decent quality vises. Maybe all of them will be great.

My mill isn't a super stable, extremely high precision machine,, so I'm fairly confident that these will work fine. In the end it's up to me to ensure everything is straight and squared up before I start milling, irregardless of the work holding method.

Again, all the advice I've been given is greatly appreciated.

Ken

My mill isn't a super stable, extremely high precision machine,, so I'm fairly confident that these will work fine. In the end it's up to me to ensure everything is straight and squared up before I start milling, irregardless of the work holding method.

Again, all the advice I've been given is greatly appreciated.

Ken