gerritv

Gerrit

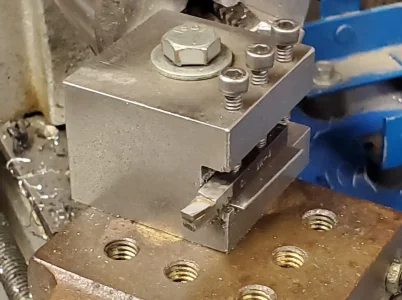

@Mcgyver, that looks very much like an 011 size. They are officially 32.5mm tip to back and 17.9mm high. I would greatly appreciate either dimensions of the internals, esp. the cam offset. Or I could pick it up from you, do the drawings/CAD and return it.

For those who don't know about Tripan, they have sizes from 011, 11 and 111 (and up.) 011 is great for watchmaker lathes such as Boley and Lorch. Mine when built is for my Sherline, might need a small riser block. The 111 is suitable for 9-10" lathes. Catalog is here: (I am not responsible for damage to your bank account) https://tripan.ch/wp-content/uploads/2021/08/CATALOGUE_TRIPAN_2021_FR.pdf

gerrit

For those who don't know about Tripan, they have sizes from 011, 11 and 111 (and up.) 011 is great for watchmaker lathes such as Boley and Lorch. Mine when built is for my Sherline, might need a small riser block. The 111 is suitable for 9-10" lathes. Catalog is here: (I am not responsible for damage to your bank account) https://tripan.ch/wp-content/uploads/2021/08/CATALOGUE_TRIPAN_2021_FR.pdf

gerrit