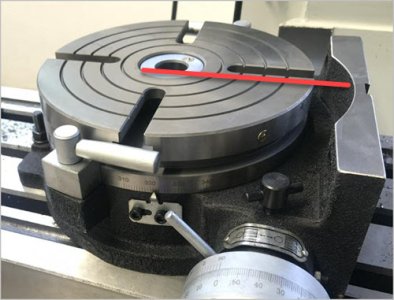

No slots! I made this table from an 9" x 1" cast iron disk with the tooling holes on a 20x20mm grid. I find this to be much more versatile than the traditional T slots. These use M6 screws and all the fittings can be used on all my machines. I can easily attach a small vice, squares and clamps to mount pretty much anything. This rotary table is also a precision indexer. The holes are all plugged with M6 setscrews to prevent the swarf filling the threaded holes.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rotary table and the number of slots

- Thread starter Hruul

- Start date

1018Machine

Well-Known Member

Nice job Susquatch!In your first photo, it wasn't obvious how you did it, but the photos you just provided show it is very similar to mine.

As you spend more time here, you will come to know that hijacked threads are a part of the culture on this forum.

No apologies needed.

I would have did the same but I wanted the encoder as flat as possible to stay out of the way.

Good to know about the hijack stuff too 😀

1018Machine

Well-Known Member

This rotary table is also a precision indexer.

That's sweet Arbutus!

Multiple ways to skin a cat. The three-jaw back mount chuck is on a backplate with slots to match the four slots on the little rotary table. Relatively easy to center with a bit of effort and a dial indicator. The four jaw is a front mount, with the back machined with tabs to line up with the table slots. Quick to setup and get close to center.

The holes are all plugged with M6 setscrews to prevent the swarf filling the threaded holes.

@CWret did the same thing. Not sure he put set screws in his though.

I "plan" to make a 14" one to expand the size of my 10" RT. I'll remember that little trick!

ChazzC

Ultra Member

Looking good!No slots! I made this table from an 9" x 1" cast iron disk with the tooling holes on a 20x20mm grid. I find this to be much more versatile than the traditional T slots. These use M6 screws and all the fittings can be used on all my machines. I can easily attach a small vice, squares and clamps to mount pretty much anything. This rotary table is also a precision indexer. The holes are all plugged with M6 setscrews to prevent the swarf filling the threaded holes.

View attachment 55555

It looks like you used a combination of linear & radial layout for the holes?

SMW (Saunders Machine Works/NYC-Cnc on YT) has free 3D printing files for M6 & 1/4” hole plugs:

https://saundersmachineworks.com/products/1-4-m6-fixture-plate-plugs?_pos=3&_sid=0ee4311ab&_ss=r

OMG. I think I have the baby brother.Multiple ways to skin a cat. The three-jaw back mount chuck is on a backplate with slots to match the four slots on the little rotary table. Relatively easy to center with a bit of effort and a dial indicator. The four jaw is a front mount, with the back machined with tabs to line up with the table slots. Quick to setup and get close to center.

View attachment 55559

Looking good!

It looks like you used a combination of linear & radial layout for the holes?

SMW (Saunders Machine Works/NYC-Cnc on YT) has free 3D printing files for M6 & 1/4” hole plugs:

https://saundersmachineworks.com/products/1-4-m6-fixture-plate-plugs?_pos=3&_sid=0ee4311ab&_ss=r

I use the SMW two-part vices and their M6 locating studs with this table.

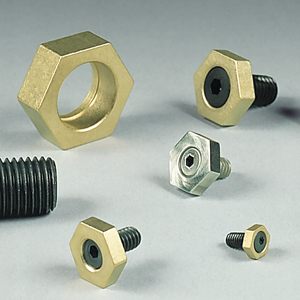

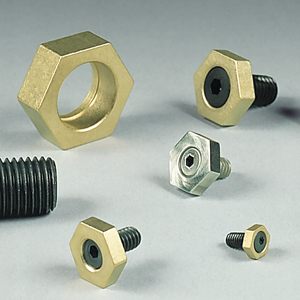

I like how you think. Another accessory if you haven't already made some - a MiteeBite type clone. I replicated the cam screw using a ring pressed on a slightly turned down socket head cap screw. Actually, rather than the MB hex shape, I turned a larger diameter sacrificial disc that I could machine to specific requirements for lathe faceplate work finicky holding, same cam clamp concept.These use M6 screws and all the fittings can be used on all my machines.

Fixture Clamps

Fixture Clamps The Cam Action MITEE-BITE Fixture Clamp is made up of two simple components: a hardened steel socket cap screw with an offset head and a brass hexagonal washer. - Low profile for quick and easy installation for linear motion guide rails - Cam action...

ps is this a Quorn?

You have a sharp eye!I like how you think. Another accessory if you haven't already made some - a MiteeBite type clone. I replicated the cam screw using a ring pressed on a slightly turned down socket head cap screw. Actually, rather than the MB hex shape, I turned a larger diameter sacrificial disc that I could machine to specific requirements for lathe faceplate work finicky holding, same cam clamp concept.

Fixture Clamps

Fixture Clamps The Cam Action MITEE-BITE Fixture Clamp is made up of two simple components: a hardened steel socket cap screw with an offset head and a brass hexagonal washer. - Low profile for quick and easy installation for linear motion guide rails - Cam action...www.miteebite.com

ps is this a Quorn?

View attachment 55575

A great idea that I plan to steal. TksThe holes are all plugged with M6 setscrews to prevent the swarf filling the threaded holes.

I couldn't remember (for sure) the size & pitch of the holes in my fixture plate - so this morning I checked it so that I could order some set screws. The plate now has a home (out of harm's way) on the side of a storage shelf. see pic:

I guess it was exposed to a lot of grinding dust (while on the back of the work bench) before I gave it a proper storage spot. Today i saw plenty of dirt / crud in the holes. So absolutely I will be getting the set screws. (Box of 100 are $20)

Above Susq referred to my fixture plate, here’s my post about it:

I started to make a fixture plate for my 8” RT last year but finally (hurried up and) got it done in time to take it to the Ontario meetup. It generated some interest so I decided to show it here too.

These are an easy and inexpensive build that greatly increases the capacity of your RT and is significantly easier to manage (lighter) than a monster 12” RT (T slots would be nice in a fixture plate but this design is much easier and lighter).

It is 13.5” diameter because thats the largest circle I could cut from the old (rusty) piece of 5/8” plate that I had kicking around.

It...

These are an easy and inexpensive build that greatly increases the capacity of your RT and is significantly easier to manage (lighter) than a monster 12” RT (T slots would be nice in a fixture plate but this design is much easier and lighter).

It is 13.5” diameter because thats the largest circle I could cut from the old (rusty) piece of 5/8” plate that I had kicking around.

It...

- CWret

- Replies: 13

- Forum: Shop and Shop Tools

Regarding plates, this consideration will be obvious rather immediately. The vertical casting element on some RT's extend past the RT table datum. I suspect they do that to give added footprint stability when RT is used in upright position. So depending on the situation, may have to relieve the underside outer portion of shop made tooling plate to clear. Or, decide if buzzing off some of the the casting extension is worth it. I think some may be ground parallel to the table, but probably RT specific.

Attachments

ChazzC

Ultra Member

Thanks - that explains the pattern. I have a 10" x 6" SMC Universal Fixture Plate with 1/4-20 holes (no longer available; smallest they now have is 14" x 6") that I selected so it will fit next to my vise; I also have the Hobby Mod Vise; I got the SMW Jaw Inserts, but got Mitee-Bites & Fixture Clamps from Zoro with a 20% discount and free shipping.View attachment 55572

I use the SMW two-part vices and their M6 locating studs with this table.

My Sherline plate uses their 10-32 standard hole system, so I'll have to see if the Mod-Vise would work: I can always make some special hold-down screws (or make a round plate with 1/4" holes to fit the Sherline RT. I would have to duplicate the SMW hole pattern if I want to use the pins to align the fixed jaw, but it would be easier to cut a round from one go my blank fixture plates and make a special set of pins (another project to add to the "After Shoulder" list – it keeps getting longer!).

Last edited:

Or, decide if buzzing off some of the the casting extension is worth it. I think some may be ground parallel to the table, but probably RT specific.

My table has no vertical option so I can make my fixture plate as big as I want. I chose 14 only because 12 is just 1" per side. 14 is 2" per side. And, well, why not!

Can you show a photo of that being used. Having trouble visualizing that.Thanks - that explains the pattern. I have a 10" x 6" SMC Universal Fixture Plate with 1/4-20 holes (no longer available; smallest they now have is 14" x 6") that I selected so it will fit next to my vise; I also have the Hobby Mod Vise; I got the SMW Jaw Inserts, but got Mitee-Bites & Fixture Clamps from Zoro with a 20% discount and free shipping.

View attachment 55583

My Sherline plate uses their 10-32 standard hole system, so I'll have to see if the Mod-Vise would work: I can always make some special hold-down screws (or make a round plate with 1/4" holes to fit the Sherline RT. I would have to duplicate the SMW hole pattern if I want to use the pins to align the fixed jaw, but it would be easier to cut a round from one go my blank fixture plates and make a special set of pins (another project to add to the "After Shoulder" list – it keeps getting longer!).

ChazzC

Ultra Member

Hey, I was digging around and found that I had posted my extra long thread on the RT on Hobby-Machinist (I have a sub-forum there which makes it easier to sub-divide posts & threads). I apologize for not yet posting on this forum, but until I'm in a little less pain, here's the link to H-M:Not on a Mini-Mill: the Sherline 4” plus 5” plate is perfect. I have a somewhat lengthy post for my “Happening” thread showing the various accessories for my Sherline (my shoulder threw a wrench in completing it), but I should have it posted soon-ish.

https://www.hobby-machinist.com/threads/tools-tooling.113630/post-1168990

Can you show a photo of that being used. Having trouble visualizing that.

I assume you mean the Mod Vise; unfortunately, due to my left arm being out of commission I can’t do any setups (the photo I posted was taken when I first got the plate & Mod Vise 2 years ago), but here are some videos:

And the Hobby Mod Vise page: