calgaryguy

Chris

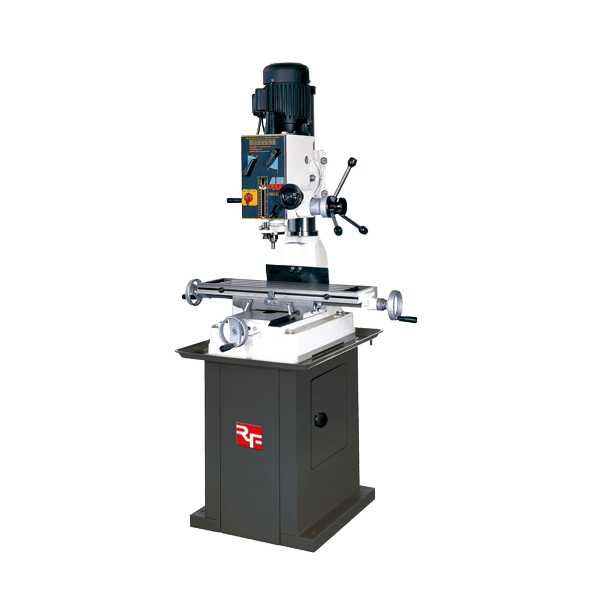

My neighbour has a RF-40 round post mill. Looks identical to this

rongfu.com

rongfu.com

The downfeed has a massive amount of backlash in it. Its atrocious - and its not consistent - sometimes it will be - .020-.025 and others its .035+. The downfeed mechanism looks exactly like the ones on a RF-30 round post mill, eg is below.

I removed the entire downfeed assembly on my neighbours mill via the two capscrews that hold it to the main body, cleaned and inspected it to see if there was a way to improve the backlash. I couldnt see any means for improving backlash, but was struck by how poor the worm gear attached to the front round fine adjust dial mated with the gear thats part of the side downfeed mechanism.

I'll be using his mill from time to time until i *maybe* get my own, and wouldnt mind trying to improve this aspect of his machine.

Does anyone know of any methods, resources, or common approaches for improving backlash in this downfeed mechanism?

Gear Head Bench Type Milling Drilling Machine - RF-40 - RongFu

Gear Head Bench Type Milling Drilling Machine - RF-40

rongfu.com

rongfu.com

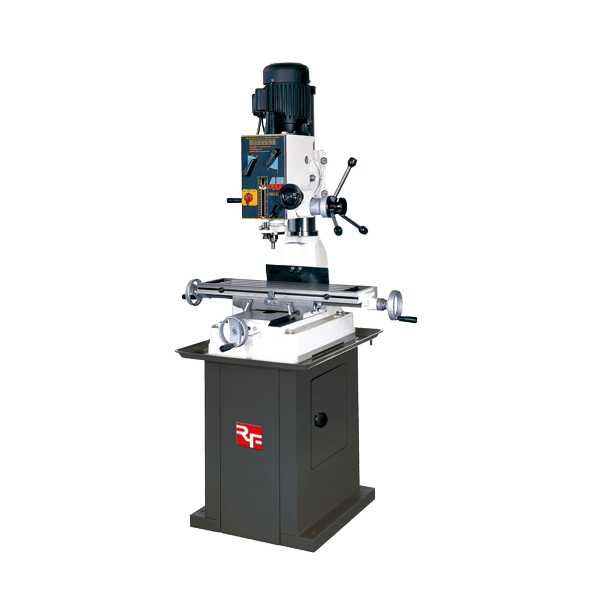

The downfeed has a massive amount of backlash in it. Its atrocious - and its not consistent - sometimes it will be - .020-.025 and others its .035+. The downfeed mechanism looks exactly like the ones on a RF-30 round post mill, eg is below.

I removed the entire downfeed assembly on my neighbours mill via the two capscrews that hold it to the main body, cleaned and inspected it to see if there was a way to improve the backlash. I couldnt see any means for improving backlash, but was struck by how poor the worm gear attached to the front round fine adjust dial mated with the gear thats part of the side downfeed mechanism.

I'll be using his mill from time to time until i *maybe* get my own, and wouldnt mind trying to improve this aspect of his machine.

Does anyone know of any methods, resources, or common approaches for improving backlash in this downfeed mechanism?

Last edited: