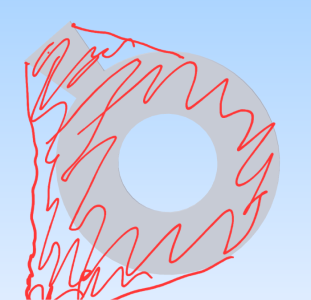

You've just given me an idea. I'm going to make a washer and see if that will work.

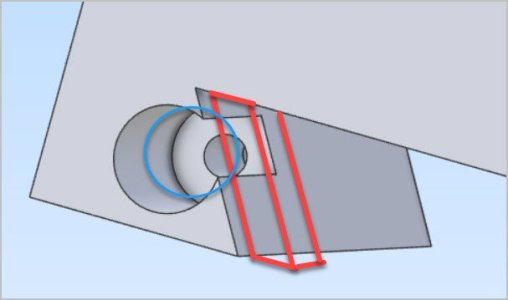

Just thinking about how my various gibb systems work. Could you make a washer type clip to capture the gibb but act like a washer under the screw? I'm thinking about those bridge clamps that hold down a carbide insert. If course, that shape wouldn't work, but it's easy for me to imagine a shape that would.

I'm even thinking about the gibb screw on my cross-slide. When I adjust it, it lifts the gibb just like another poster described a while back. A clip that fit the entire gibb cavity would push on the gibb but not rotate and lift it.