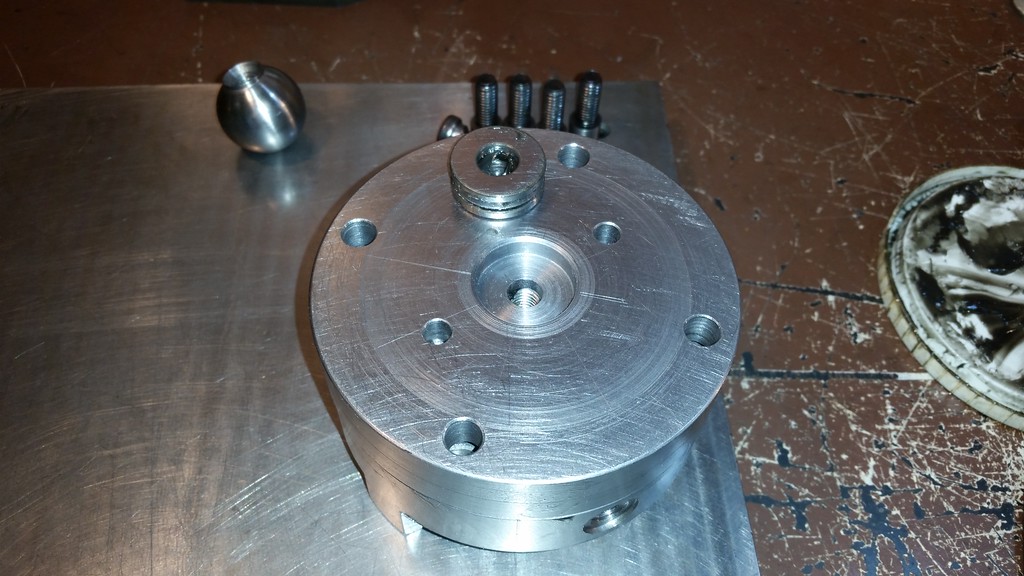

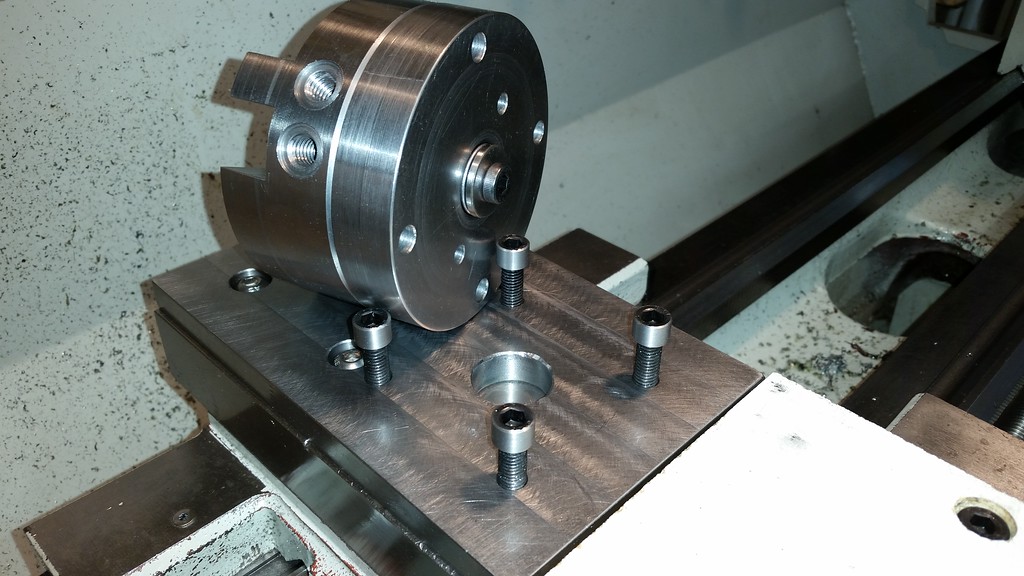

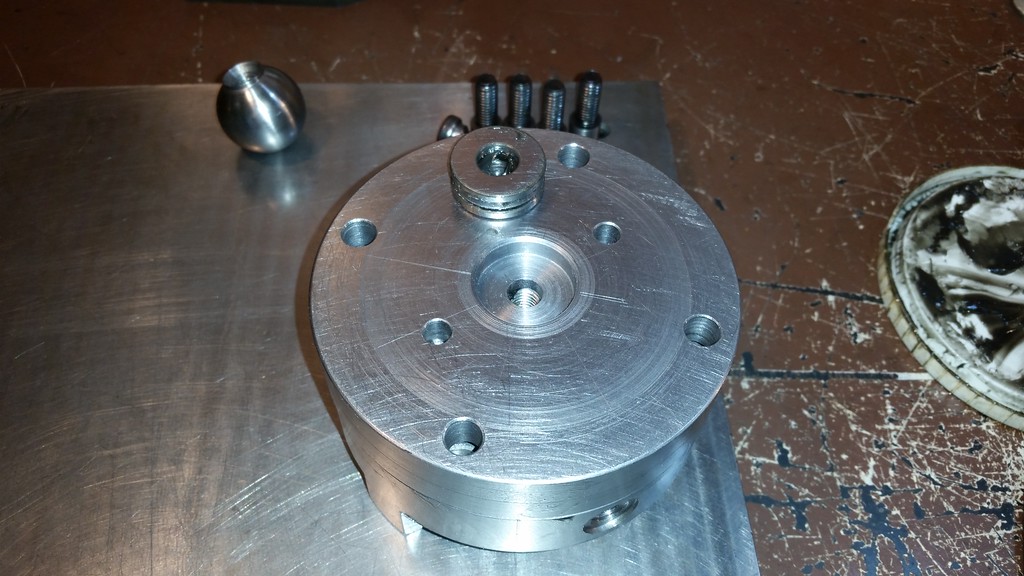

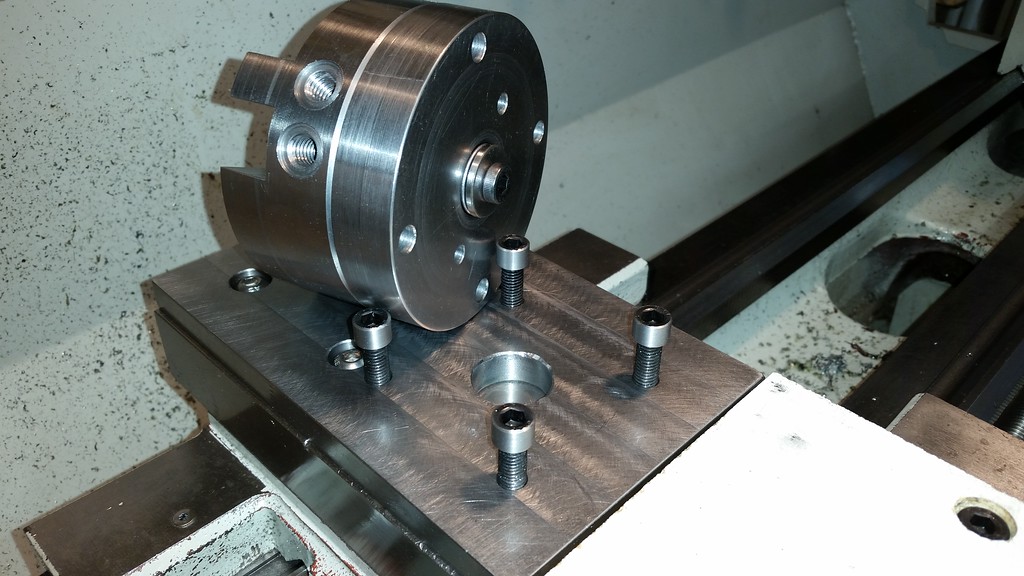

I have been thinking about building a radius turning tool for a while now. I have been working on plans in my head for a couple of weeks now and got to work on it this weekend. My lathe has t-slots on the cross slide so I machined some t-nuts and a mounting plate for the body of the radius tool. The compound does need to be removed to use it but the cross slide stays more centered in it's travel so I chose not to mount it using the compound bolts. I copied a design I saw on another forum but added a second bearing. It has a tapered roller bearing on the top and a thrust ball bearing on the bottom. The bearings are packed with grease and slightly preloaded which makes for very smooth stable turning action. The cutter head is mounted to an adjustable slide that is secured from one side with four m8 set screws. The cutter head can be mounted 2 ways to provide more options for different size radii. It can machine a ball up to 3.125 inches in diameter and can be adjusted to make a large range of concave radii as well. I made a couple of balls, one for the handle of this tool and 1 for the spindle clamp on my mill. They came out pretty smooth and didn’t need much polishing to be made shiny smooth. It uses a TCMT insert which has a 6 degree positive rake.