Ironman

Ultra Member

One of my favourite guys, Joe Pie has a short vid on how to create a height standard.

What he says makes sense to me.

What he says makes sense to me.

One of my favourite guys, Joe Pie has a short vid on how to create a height standard.

What he says makes sense to me.

A Vernier "dial" caliper, much easier. A Vernier "digital" caliper, kind of a no brainer. And so on.

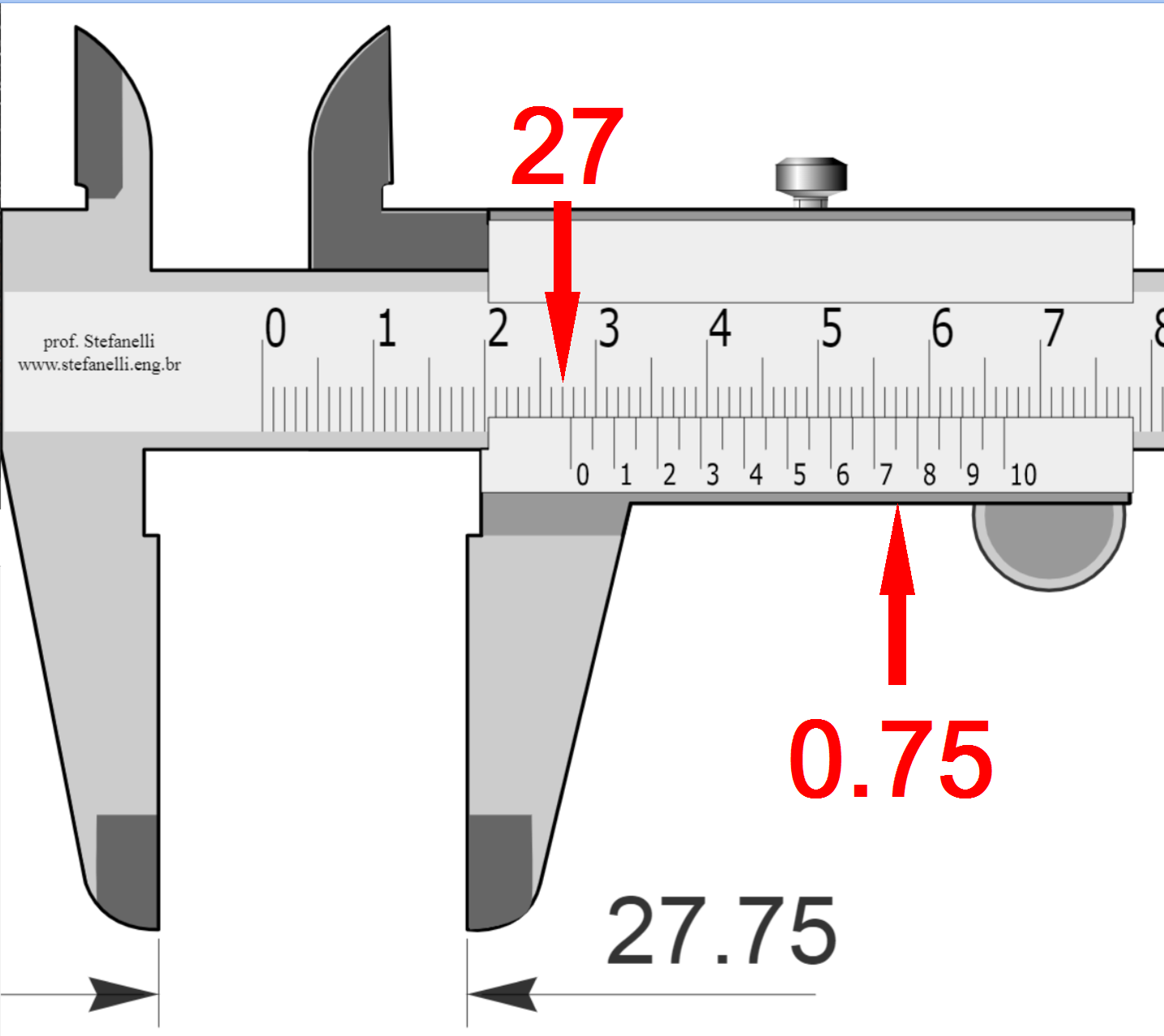

Personally, I can't recall anyone ever calling them vernier digital calipers or digital vernier calipers, just digital calipers, or calipers, the one that gets me is all the people that call a face mill a fly cutter.Actually, I'd like to kick that no brainer out of your head if you will let me. The word Vernier refers to the two side by side scales that are etched into the metal - they are deliberately offset in such a way that allows you to see which one lines up best. The best match gives you the last digit (thousandth) or sometimes more of the measirement. You can have Vernier scales on all kinds of different devices ranging from Calipers to rotary tables. It's a very precise mechanical way to get very fine resolution. There are even programs on the net that you can use to make your own Vernier scales.

Technically speaking, there is no such thing as a Digital Vernier Caliper. It is just a Digital Caliper.because there is no Vernier scale on it.

But you can rest assured that you are not the only one who calls them Verniers. I see them called Verniers instead of Calipers everywhere I go. But if you want to impress a machinist who really knows his stuff, just call them calipers because that's what they really are. Then add either dial or digital or Vernier or nothing. Yes, there are calipers that don't have any of the 3 types. Those ones are just plain old calipers.

If you want to keep calling them Verniers, that's ok too. It's definitely a growing trend. But when some old guy looks at you funny, at least you will know why.

.

Many digital calipers do also have scales on them, but just not the Vernier scale. I think the scale is just an alternate quick & dirty independent 'ruler' for your eyeball. Hard to know why manufacturer decided to include or omit. Maybe as a sanity check to the common offshore models that lose their display marbles when the power goes off. Turn the power on again, jaws happen to be open 0.25", display says 0.000" & does not line up to the scale. OK I'm grasping at straws here. Sometimes scale is etched, sometimes its a sticker (and not well aligned if you examine real cheap models). It cant cost much or they would skip it altogether.

Many digital micrometers also have thimble scales on them. I may have even seen one that also has the Vernier scale, but for sure it is not the norm. Again, why I'm not sure why. Maybe to please a larger age span machinists so the same mic can be used by either or? Or if the battery dies you are still in business? Or it uses common parts from mechanical line & they don't have to re-tool? Kind of a side note but something to consider on digital mics when buying, there are different permutations. Some have an IMP/MET switch which seems obvious enough. These could have MET engraved thimble, or IMP engraved thimble, or no engravings on thimble. Then there are MET or IMP which digital display of those units only, no IMP/MET switching.

^^^This^^^This (and for other reasons too) is why I really like making and using a tool height standard. I use it virtually every time I change tools. It takes seconds to do and prevents all kinds of errors. It is my belief that the very first tool any lathe owner should make is a tool height standard.

As it turns out, I've never needed to adjust it. The center height of my lathe has never changed.I'm not keen on the magnet, but I LOVE the adjustability!

Agree that "MACHINISTs" are supposed to be precise but that is why this site is titled "HOBBY" as very few of us, myself included, are "MACHINISTs". So if you wish to correct someone in what maybe an incorrect term to you that's okay but here you must expect errors in machine use and terminology.I also get irritated when people use incorrect terms like calling digital calipers "verniers". Machinists are supposed to be precise, that should apply to speech as well as parts.

As it turns out, I've never needed to adjust it. The center height of my lathe has never changed.

I suppose if I got another lathe....

I sure hope my machining never gets as bad as my English 😛Agree that "MACHINISTs" are supposed to be precise but that is why this site is titled "HOBBY" as very few of us, myself included, are "MACHINISTs". So if you wish to correct someone in what maybe an incorrect term to you that's okay but here you must expect errors in machine use and terminology.

It's the same for the brand of machinery used by the members, no one cares what brand machines are used it's all about how it's used and the enjoyment of making and sharing things.

If you ever work in a place where they are dragging junk in the door to be fixed every day, you would realize that hobby machinists are very often way more anal and whimper on about a 1/2 thou. Production guys soon realize the customer just wants it to be round again. I remember using a Polish lathe one time in a shop and it was out by .5 in a foot and I could not do a job on it. Told the boss and he called an old guy over and said can you help. This guy knew how to keep backing out the crossfeed as it progressed and got it round enough and it would fit the bearing. Accurate? Naa. I asked why not line it up and fix it. He said it works fine as it is.Agree that "MACHINISTs" are supposed to be precise but that is why this site is titled "HOBBY" as very few of us, myself included, are "MACHINISTs". So if you wish to correct someone in what maybe an incorrect term to you that's okay but here you must expect errors in machine use and terminology.

It's the same for the brand of machinery used by the members, no one cares what brand machines are used it's all about how it's used and the enjoyment of making and sharing things.

They don't understand....