we're real good at spending other people's cash...Just do it man. You aren't getting any younger. What do you even work for if you can't buy what you want? You're getting a good deal. Are you going to wait another year?

hope this helps

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Prusa core one

- Thread starter Janger

- Start date

I'm not on the board any more but... I always thought the rule should be you don't have to be Canadian but you better be damn Canadian in your attitudes. No assholes. I think we have generally accomplished that. We do have a locker room mentality at times, probably quite the turn off, I could never figure out how to change that.The very name of our forum would suggest that we are mostly Canadian and that was our founding target. But we have certainly grown to include many others from all around the world. There is no requirement to be Canadian.

I sincerely believe she would be welcome here. We embrace a wide range of skill sets - from newbies to wise old pros. She would fit right in from that perspective.

Our membership has very loppsided male representation. Some think it is self imposed. Who am I to say no. But I don't believe for one minute that it's deliberately exclusionary. It's just an outcome not a deliberate goal. In fact, I'd say there isn't even one member on here who wouldn't welcome her with open arms.

Last edited:

Prusa needs in country distribution to cut delivery times and drastically reduce shipping costs. The Core One is $140USD for shipping + whatever extras the courier squeezes. Call that $225CAD all in. And Bambu is free/included?Well, I bought a Bambu P1S 2 weeks ago (after my Ender threw a final hissy fit) and I have to say it is a very impressive piece of kit for $890 including taxes & delivery. I bought the plain jane version without the multi-filament feeder (called the AMS) since I have no interest in the extra hassles involved.

I feel really bad for Prusa - smart people building good products in country - China comes along and it's not 20% less it is half the cost for something similar. What can Prusa do? Cut quality, outsource to China, innovate and design a revised CoreXY for $750USD? Or build something other people are not. How about a prosumer DLP printer delivering 10x print speed performance for $1500USD? Make a cheap DLP printer with Prusa consumables for a premium but reasonable price. i.e. the inkjet printer model. HP has made a lot of money selling cartridges.

Today I was comparing the Prusa Core one to the Bambu X1C. They have the same price in USD on the bambu USA web site vs Prusa web site $1199. I think Prusa is trying position the Core One as equivalent to the X1C, not the P1S as we seem to be doing. So, is the Core One comparable to the X1C? Here is the bambu comparison page between X1 and P1 series. I'm not sure what to think.

bambulab.com

bambulab.com

Compare all 3D printers - Bambu Lab

Compare features and technical specifications for the Bambu Lab 3D printers and see what makes each model different. Bambu Lab X1C, P1P, P1S, A1, A1 mini.

TorontoBuilder

Sapientia et Doctrina Stabilitas

I would not. My wife wud kill me.In fact, I'd say there isn't even one member on here who wouldn't welcome her with open arms.

But I'd welcome her with an open mind.

If we are recruiting scottish electrical engineers I'd suggest we also recruit Big Clive.

We're not recruiting per say. I've mentioned the group to Katie and I've posted links to some of the things she's doing. She's in the middle of building a new shop for her wood working tools and CNC router etc.I would not. My wife wud kill me.

But I'd welcome her with an open mind.

If we are recruiting scottish electrical engineers I'd suggest we also recruit Big Clive.

She checked out the group and told me pity it's just for Canadians. Turns out not and I've told her that.

It's up to her to decide to join or participate and at whatever level. So far my interaction with her has been much the same as with everyone here. She knows stuff I don't know just like on this list. She seems like a nice person.

She's a big Bambu 3D printer fan and is churning out some innovative solutions. From the advice of the people here on this group and her I have an X1C ordered that now has a FedEx tracking # attached to it. Black Friday sale. Couldn't pass it up and my original 10 year old 3D printer has bed heater/sensor problems. Time to retire it. The SOVOL is doing well but it's not enclosed and I can't do ABS or some of the other more exotic plastics.

Oh crap John. Now I have major printer envy!We're not recruiting per say. I've mentioned the group to Katie and I've posted links to some of the things she's doing. She's in the middle of building a new shop for her wood working tools and CNC router etc.

She checked out the group and told me pity it's just for Canadians. Turns out not and I've told her that.

It's up to her to decide to join or participate and at whatever level. So far my interaction with her has been much the same as with everyone here. She knows stuff I don't know just like on this list. She seems like a nice person.

She's a big Bambu 3D printer fan and is churning out some innovative solutions. From the advice of the people here on this group and her I have an X1C ordered that now has a FedEx tracking # attached to it. Black Friday sale. Couldn't pass it up and my original 10 year old 3D printer has bed heater/sensor problems. Time to retire it. The SOVOL is doing well but it's not enclosed and I can't do ABS or some of the other more exotic plastics.

Mwwaaaaha ha ha ha....Oh crap John. Now I have major printer envy!

I've been into the 3D printing for over 10 years. A number of people had the unit I still have. They added metal frame supports to the top to keep it from rocking. What really made these old printers and even my new SOVAL so easy to use was the Raspberry Pi and Octoprint interface. From my laptop all the printers look and behave the same. Especially with the camera looking at it. And the number of features that Octoprint has like relay control for lighting, heating, fans and all sorts of other things make it a superb environment.

That's where the Bambu worries me. No hard ethernet connection. Custom user interface. Apparently it can even have microchips in the reels so the printer knows what type of filament is there. But it has a built in camera and can do exotic materials. Not looking forward to learning a new user interface but apparently if I wanted to speed up my SOVOL with a Klipper module I'd have to let go of Octoprint too.

So there it is.

That's where the Bambu worries me. No hard ethernet connection. Custom user interface. Apparently it can even have microchips in the reels so the printer knows what type of filament is there. But it has a built in camera and can do exotic materials. Not looking forward to learning a new user interface but apparently if I wanted to speed up my SOVOL with a Klipper module I'd have to let go of Octoprint too.

So there it is.

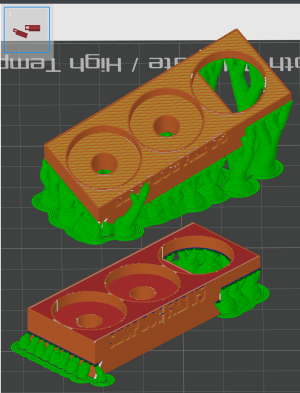

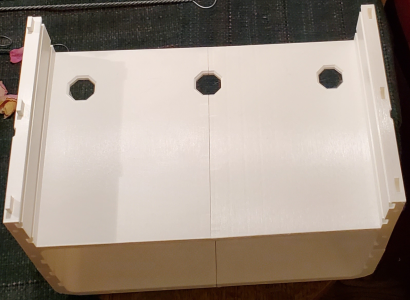

Meanwhile progress on the Herbus cabinet. This is already 4 pieces held together with rectangular dowels. Two more sides to go. Then the two top pieces. Each door, front and back requires 4 prints. So far the average time of each print is about 11 hours. Apparently the Bambu can cut that time in half. Just like the Klipper software could make my SOVOL go faster.

The barcode on the spool is a thing of beauty. You load it in and Bambu studio knows what it is and adjusts all the settings/imports the filament profile. It really works well, but of course, only if you buy the filament from them. I literally had prefect prints every time using Bambu filament. When I tried to save a few bucks, I had to mess around modifying settings and googlin till I got it to work. I wish Bambu had an Amazon store., but I've now got a few print profiles that work well with Elegoo Rapid PLA+ etc.

I don't know if this is specific to the heated chamber of the X1C, but the best thing I learned for me as a noob, is using hairspray on the plate instead of gluesticks. You can have the bestest/fastest printer but if your part comes loose 3 hours into a print, you're hooped. My failed prints went from like 2/20 to 1/200.

I don't know if this is specific to the heated chamber of the X1C, but the best thing I learned for me as a noob, is using hairspray on the plate instead of gluesticks. You can have the bestest/fastest printer but if your part comes loose 3 hours into a print, you're hooped. My failed prints went from like 2/20 to 1/200.

Meanwhile progress on the Herbus cabinet.

So you make birdhouses on the side eh!

I have a bambu A1 mini. With bambu brand PLA it prints quickly and does a nice job - however, I find the prints are weak. This was printed in PLA with 100% infill, I broke it accidentally with my fingers. I'm not sure if this is just PLA, or the printer? I usually use PETG with my Prusa and find that material is much stronger. This same part on the Prusa with PETG is fine no brittleness or weakness. I should print this again with PETG on the A1 and see. Are members using PETG in their X1 P1 etc and how do you find the print strength? Or maybe how is the print strength with PLA in your experience?The barcode on the spool is a thing of beauty. You load it in and Bambu studio knows what it is and adjusts all the settings/imports the filament profile. It really works well, but of course, only if you buy the filament from them. I literally had prefect prints every time using Bambu filament. When I tried to save a few bucks, I had to mess around modifying settings and googlin till I got it to work. I wish Bambu had an Amazon store., but I've now got a few print profiles that work well with Elegoo Rapid PLA+ etc.

I don't know if this is specific to the heated chamber of the X1C, but the best thing I learned for me as a noob, is using hairspray on the plate instead of gluesticks. You can have the bestest/fastest printer but if your part comes loose 3 hours into a print, you're hooped. My failed prints went from like 2/20 to 1/200.

Pretty narrow section where the break is. Broke right on the layer seam. Turn it 90 degrees and print it on the edge. Or try using a raft and print it on a 45 degree angle.

I find the PLA stiff and brittle.

These would easily break right where it tapers down. Again you see the layer lines and the thin area. Instead of printing in a different orientation I printed them in PETG.

I find the PLA stiff and brittle.

These would easily break right where it tapers down. Again you see the layer lines and the thin area. Instead of printing in a different orientation I printed them in PETG.

Last edited:

Plain ordinary PLA is brittle, yet quite stiff. PLA+ or PLA Professional is less brittle, and it will deform slightly before fracturing which seems to make it "stronger".I have a bambu A1 mini. With bambu brand PLA it prints quickly and does a nice job - however, I find the prints are weak. This was printed in PLA with 100% infill, I broke it accidentally with my fingers. I'm not sure if this is just PLA, or the printer? I usually use PETG with my Prusa and find that material is much stronger. This same part on the Prusa with PETG is fine no brittleness or weakness. I should print this again with PETG on the A1 and see. Are members using PETG in their X1 P1 etc and how do you find the print strength? Or maybe how is the print strength with PLA in your experience?

View attachment 55057

For sections like the one you show there, the print orientation - i.e. the layer direction vs. the strain direction is probably the main factor contributing to this break. The cross section is only a few mm square so the inter-layer bonding is taking all the load. For this particular print, I would use the slicer to reorient the print so that the grain follows the outline contours.

Also, the design details matter. I always use fillets, never 90 degree corners. I also chamfer edges, use appropriate clearances, lubrication on jointed parts (vaseline).

Yes, PETG is stiffer and might survive, but careful design is the better solution in most cases.

I use hair spray on the glass plate printer. Only needed it once on the SOVOL textured surface. For the most part a BRIM helps hold down small parts.

Right now while the weather is nice she's busy putting a roof onto her new shop (8m x4.5m or about 26'x15'. Very envious. Really should build a triple car garage on our property but then I'd be spending more time turning it into a shop and no time building fun stuff.

It's a grow seedling green house growing chamber that Katie designed. Still at the revision 0.6 and I think I'm the first two build the entire thing which is why I'm finding little glitches.So you make birdhouses on the side eh!

Right now while the weather is nice she's busy putting a roof onto her new shop (8m x4.5m or about 26'x15'. Very envious. Really should build a triple car garage on our property but then I'd be spending more time turning it into a shop and no time building fun stuff.

temp towers....testing settings for your filament. sounds like a good idea. Got any more information on this?I print temp towers when I try new filament so that I can find the optimum temp.

My PLA prints are very strong. All the printed parts on my CNC router are PLA and they are holding up fine after 3 years.

I'm using the bambu filament with the rfid chip which sets up with the "right" parameters supposedly automatically. The slicer knows the filament type and colour so I think that is working. So if it is set up correctly then why does it not seem like it is?

Plain ordinary PLA is brittle, yet quite stiff. PLA+ or PLA Professional is less brittle, and it will deform slightly before fracturing which seems to make it "stronger".

For sections like the one you show there, the print orientation - i.e. the layer direction vs. the strain direction is probably the main factor contributing to this break. The cross section is only a few mm square so the inter-layer bonding is taking all the load. For this particular print, I would use the slicer to reorient the print so that the grain follows the outline contours.

Also, the design details matter. I always use fillets, never 90 degree corners. I also chamfer edges, use appropriate clearances, lubrication on jointed parts (vaseline).

Yes, PETG is stiffer and might survive, but careful design is the better solution in most cases.

Good insight there @Arbutus - I'm printing again with some different orientations. I like the triple 30 degree offsets on X Y Z. I've done that before and it can make a surprising difference. And I'll try PETG too.