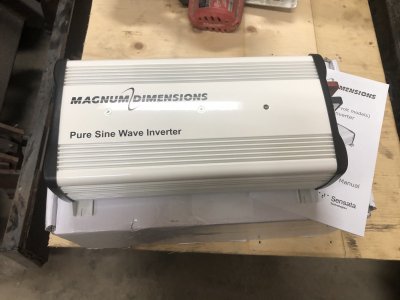

View attachment 27490Still no bueno. I’m not understanding this

Sept- Truck running, high idle, wouldn’t run the microwave

Sept- Truck running, low idle, printer plugged in (not printing), laptop wouldn’t power up

Oct 4- First phone call to tech support, 45 minutes on hold, got cut short because I had a meeting, their initial thought was the printer was a power hog (?)

Oct 28- 4 new batteries, alternator was new around May 2022, found 3 bad battery cables, fixed 2, had to leave the 3rd

Still will not run the microwave. Says it’s 1100 watt input, 700 watt output (truck running)

Owners manual says I should be running 2 gauge wire, I have 4 gauge, it’s approximately 6 feet from the batteries to the inverter

Positive for the inverter is on one battery, ground is on an opposite battery

Within 10 seconds of running the microwave, the voltmeter on the dash drops dramatically (truck running), and the error message E06 flashes, connected load is too high

Other than another call to tech support, which I’ll do next week, I’m stumped