Long story short. Wanted a Delta printer. Bought expensive, for the time, Delta printer. What a Piece of S. Slop in the universals. Plastic filament drive unable to push filament through bowden tubes. Too much play in the linear bearings so twist one of the slides and the hot end moves several mm. And the 8 bit Arduino software just was inadequate.

So I splurged on a Replicape and Touch screen for a BeagleBone Black running LinuxCNC and Octoprint and found that one of the stepper motor drivers wasn't working. Even changing drivers around in the software still had problems. This was about 6 years ago. Gave up.

It's been collecting dust. It's in the way. To make it fit the Replicape I had to replace all the connectors. Well today I put the original connectors back on. Once I correctly put the X and Z limit switches into the proper places it homed. Yahoo. It's alive.

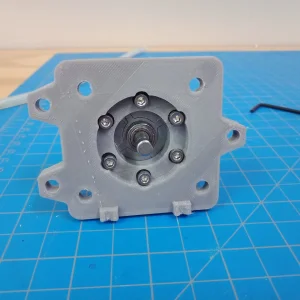

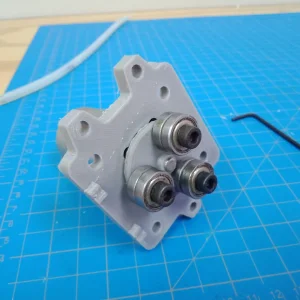

Now why am I doing this? Well it was collecting dust. The BeagleBone due to a failed Replicape and no support because the designer has moved onto other things was a total loss. So I thought now that I know more than 6 years ago perhaps I'd pick up a few more linear bearings to stabilize the motion. I've already replaced the extruder drives with all metal units. I have a whole bunch of different types of extruder nozzle assemblies.

So it's time to do something with the POS. I figure if I can make it mechanically sound then maybe one of the more advanced 32 bit controllers would handle it better.

So I splurged on a Replicape and Touch screen for a BeagleBone Black running LinuxCNC and Octoprint and found that one of the stepper motor drivers wasn't working. Even changing drivers around in the software still had problems. This was about 6 years ago. Gave up.

It's been collecting dust. It's in the way. To make it fit the Replicape I had to replace all the connectors. Well today I put the original connectors back on. Once I correctly put the X and Z limit switches into the proper places it homed. Yahoo. It's alive.

Now why am I doing this? Well it was collecting dust. The BeagleBone due to a failed Replicape and no support because the designer has moved onto other things was a total loss. So I thought now that I know more than 6 years ago perhaps I'd pick up a few more linear bearings to stabilize the motion. I've already replaced the extruder drives with all metal units. I have a whole bunch of different types of extruder nozzle assemblies.

So it's time to do something with the POS. I figure if I can make it mechanically sound then maybe one of the more advanced 32 bit controllers would handle it better.