Dan Dubeau

Ultra Member

A couple years ago I designed and made this jig. It worked great, and I've used it for quite a few little projects around the house and shop. A buddy of mine was over one day when I was building something and asked to borrow it when I was done. Well over the years he asked to borrow it so many times, the last time I told him to just keep it i'll make another one. That was a few weeks ago and I totally forgot about it, so I spent some time searching everywhere this morning for it before I remembered..... Time to get the printer out (burried under a bunch of workbench junk) and get printing. Princess auto had step drills on sale so I ordered 2 a few weeks ago. They're actually porter cable branded and IMO better than the other one I gave him with the old jig lol.

First layer went down great after sitting idle for a few months. I really like this little printer.

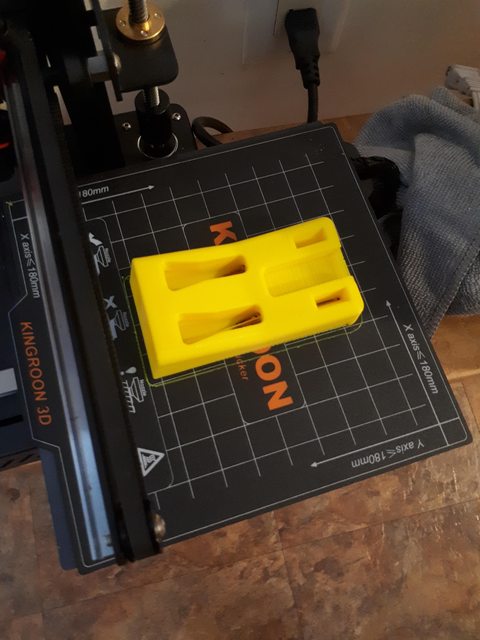

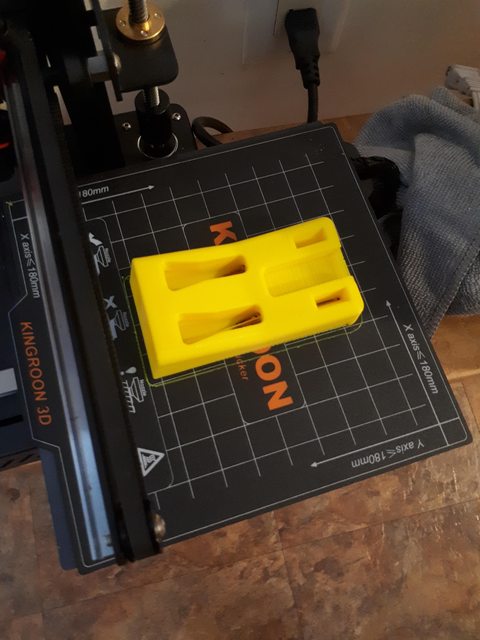

Anyway, 4 hrs later, it's done. I should redesign it to print without supports, but I can guarantee you it's a job i'll never get around to doing lol. The first one drilled a few hundred holes at least with no issues, and I bumped up the wall thickness on this one to 4mm. If I ever break this one or get to using it more, I'll just make one from aluminum. The bushings are headed 3/8" drill jig bushings. I heat them up and push them into the holes and they melt into place. The open skeleton of this design clears chips really good, and the sight windows help line up the holes. The back face is zero clearance around the drill bit so there is little tearout. I have a pile of these quick grip clamps, so I can just grab one and strip the pad off whenever I need one.

Random test piece

Now I've got some shelves and storage to make.

First layer went down great after sitting idle for a few months. I really like this little printer.

Anyway, 4 hrs later, it's done. I should redesign it to print without supports, but I can guarantee you it's a job i'll never get around to doing lol. The first one drilled a few hundred holes at least with no issues, and I bumped up the wall thickness on this one to 4mm. If I ever break this one or get to using it more, I'll just make one from aluminum. The bushings are headed 3/8" drill jig bushings. I heat them up and push them into the holes and they melt into place. The open skeleton of this design clears chips really good, and the sight windows help line up the holes. The back face is zero clearance around the drill bit so there is little tearout. I have a pile of these quick grip clamps, so I can just grab one and strip the pad off whenever I need one.

Random test piece

Now I've got some shelves and storage to make.