-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pep talk

- Thread starter Doggggboy

- Start date

I find it hard to believe that he only bought the 3D printer 6 months ago like he stated in the video. But a lot of people do rave about the Bambu Labs units.This is a good explanation of why a 3d printer in a shop is a great idea.

Doggggboy

Ultra Member

There are a lot of holdouts when it comes to 3D printing.I find it hard to believe that he only bought the 3D printer 6 months ago like he stated in the video. But a lot of people do rave about the Bambu Labs units.

Maybe even a few on this forum😉

That filament is crazy expensive though.

Last edited:

slow-poke

Ultra Member

Well, my only experience is with a used $100 Kijiji Prusa. I mostly print in PLA and I have printed countless useful prototypes and parts with near zero nerd time, tweaking or repairs.

PLA might be weak compared to better filaments, however as a timing pulley to raise and lower the knee on my mill it was strong enough, so not that weak.

PLA might be weak compared to better filaments, however as a timing pulley to raise and lower the knee on my mill it was strong enough, so not that weak.

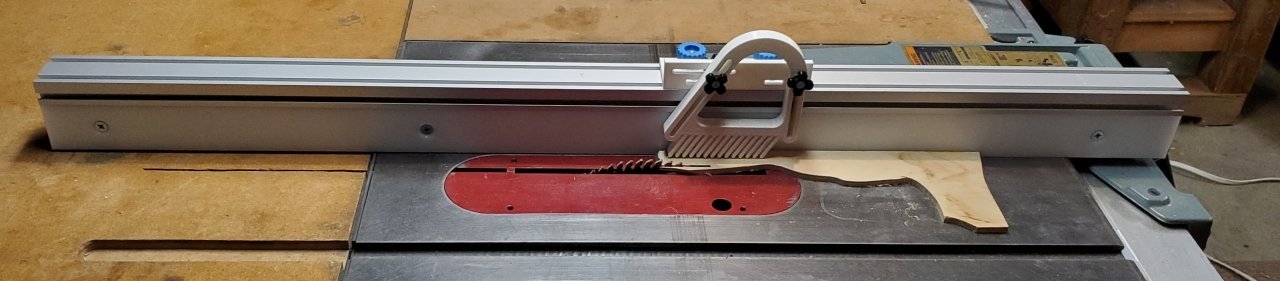

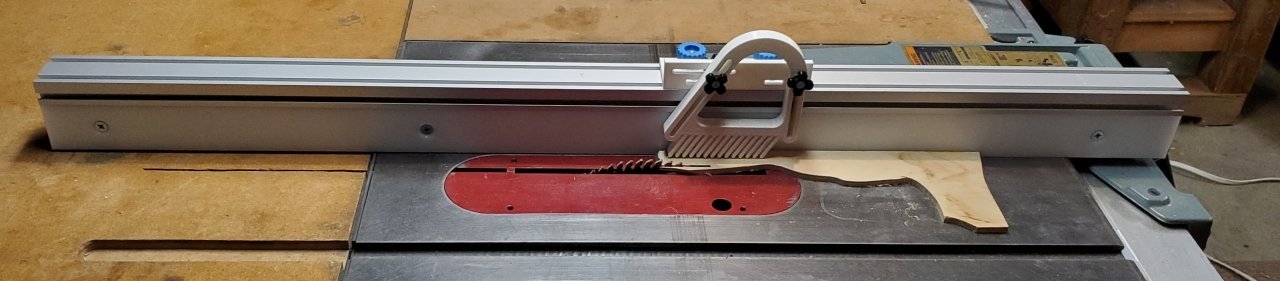

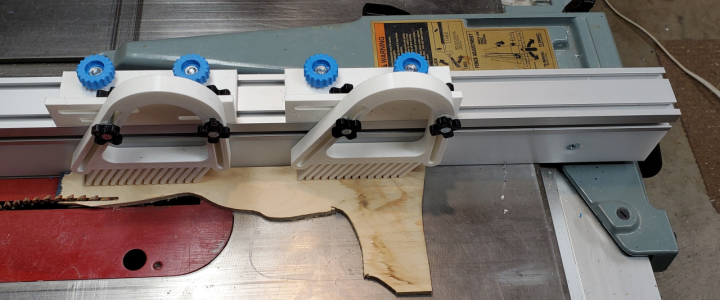

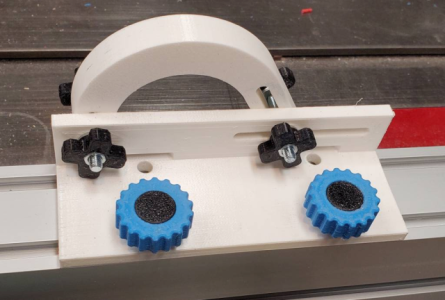

Truth be told often 3D printing is chosen because it's easy but the solution can be found in other ways. For example. @DavidR8 and I purchased a replacement extruded fence for our Delta Table Saws. The curved extrusion has always been a pain to clamp feather boards etc.

So of course as soon as it was installed the 3D printer was put to work.

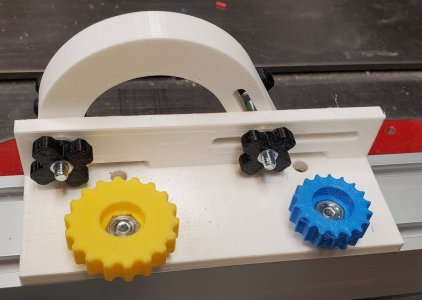

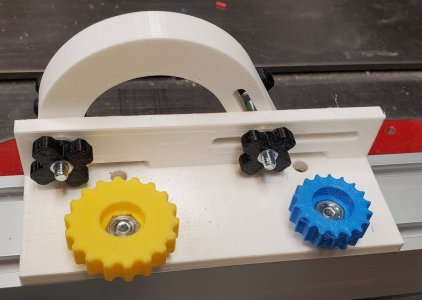

Now it's true. With some 3/4" plywood, wing nuts and bolts the same thing could have been done. And as it was I had to go to Lowes to get some 5x0.8x40mm bolts since the design I found online used 5.5mm slots and the black knobs were meant for 5mm nuts.

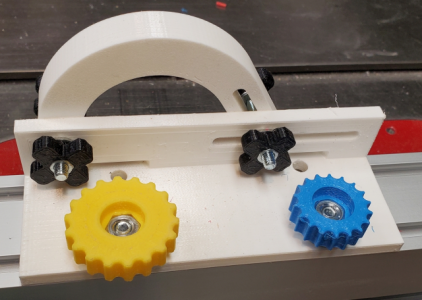

The bracket I designed myself to fit on the new fence and it uses 1/4" bolts. The first knobs I used were from the Compressor monitor project but they were a bit large. So I scaled that down and reprinted in blue.

The recess is so I can use shorter bolts and also I'll print a cap that gets glued in to retain the nut.

So of course as soon as it was installed the 3D printer was put to work.

Now it's true. With some 3/4" plywood, wing nuts and bolts the same thing could have been done. And as it was I had to go to Lowes to get some 5x0.8x40mm bolts since the design I found online used 5.5mm slots and the black knobs were meant for 5mm nuts.

The bracket I designed myself to fit on the new fence and it uses 1/4" bolts. The first knobs I used were from the Compressor monitor project but they were a bit large. So I scaled that down and reprinted in blue.

The recess is so I can use shorter bolts and also I'll print a cap that gets glued in to retain the nut.

TorontoBuilder

Sapientia et Doctrina Stabilitas

I finally got a separate 3d printer for my brother.There are a lot of holdouts when it comes to 3D printing.

Maybe even a few on this forum😉

That filament is crazy expensive though.

It has a raspberry pi and webcam so I can remotely keep an eye on his prints too. Now I just need to get him up to speed on printing. I'll still have to send him models to print though

DPittman

Ultra Member

Yup I'm one of them. I am afraid of the time commitment and learning curve that I think i will have with one. I don't want to buy technology that won't get used or learned until maybe it's obsolete. I wish I had a friend with 3D printer😉. Hell I'd be happy just having a friend😕.There are a lot of holdouts when it comes to 3D printing.

Maybe even a few on this forum😉

That filament is crazy expensive though.

140mower

Don

Awe, come on buddy....... You've always got us. 😎Hell I'd be happy just having a friend😕.

Okay, maybe I see what you

mean. 🙄

Same here.I finally got a separate 3d printer for my brother.

It has a raspberry pi and webcam so I can remotely keep an eye on his prints too. Now I just need to get him up to speed on printing. I'll still have to send him models to print though

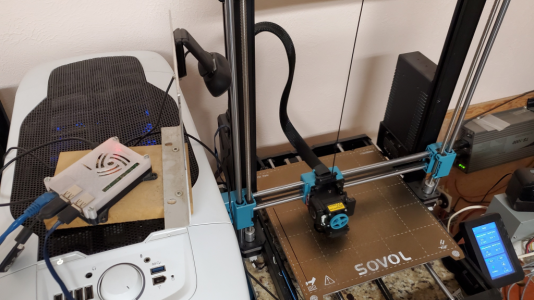

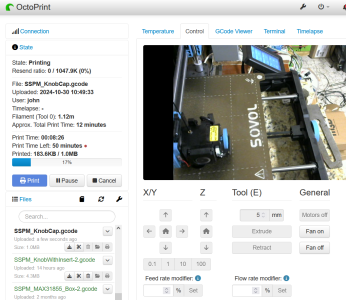

Raspberry Pi3, Camera, OctoPi Software talk via USB to the SOVOL printer.

Watch what is going on from upstairs.

And keep churning out parts I guess.

I want to get one, but my recent machine buying spree has me a bit tapped out...

I was an early adopter about 10 years ago, but I was spending so much time messing with the printer that I never made anything useful with it. I sold it all off during the pandemic.

I might be ready again, as long as I can get one that just works, and doesn't break the bank. Right now that is looking like the Bambu A1. Just a basic machine, no extras. Black Friday may have me spending more money...

I was an early adopter about 10 years ago, but I was spending so much time messing with the printer that I never made anything useful with it. I sold it all off during the pandemic.

I might be ready again, as long as I can get one that just works, and doesn't break the bank. Right now that is looking like the Bambu A1. Just a basic machine, no extras. Black Friday may have me spending more money...

I’m mildly averse, mostly because my brain was wired decades ago to think in the two dimensions of a drafting table and I’ve never been able to wrap my head around 3d CAD. I’m ok with running someone else’s STP files on my CNC routers, but the grey matter balks at designing my own.

I've tried various CAD programs over the years. Nothing clicked for me until Alibre showed up. Even now, being fairly competent with Alibre I still can't get my head around Fusion 360 or even the free FreeCAD 0.2.I’m mildly averse, mostly because my brain was wired decades ago to think in the two dimensions of a drafting table and I’ve never been able to wrap my head around 3d CAD. I’m ok with running someone else’s STP files on my CNC routers, but the grey matter balks at designing my own.

If your brain is like mine then do the free trial .

https://www.alibre.com/atom3d/

Parametric CAD, once you click so very easy.

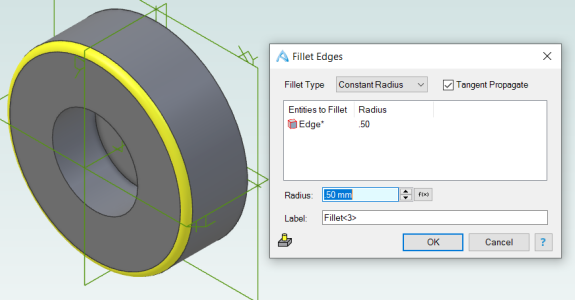

For example. The covers over the nuts on the project I just finished.

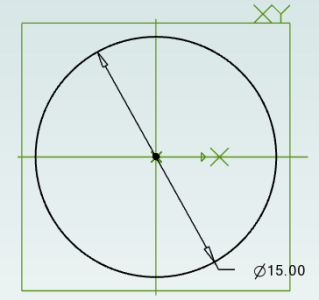

I started with a 15mm diameter circle which is called sketch<1>.

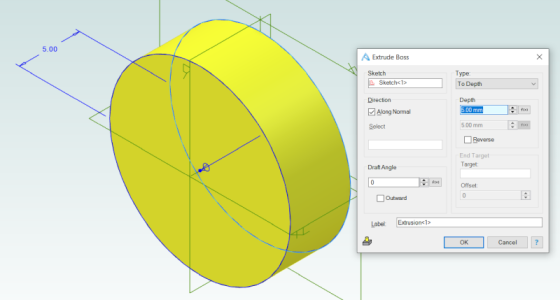

Next I extruded a boss. It's like plastic extrusion pushing melted plastic through a die. In this case for 5mm.

Now I have something equivalent to a 15mm diameter dowel cut to a length of 5mm. To make sure there's a bit of clearance for the 1/4" bolt to extend past the nut I need to put a hole in the middle.

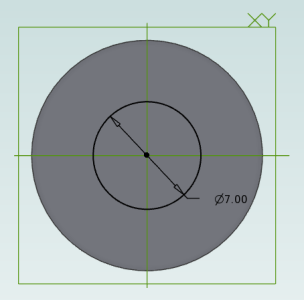

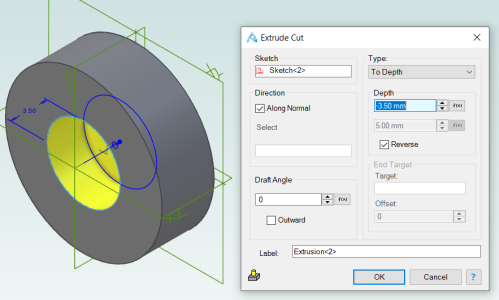

So I place a circle on the surface. 7mm diameter for that 6.35mm (1/4") bolt that might come through a bit. That's sketch2.

Instead of extruding now I'm going to cut (like drill a hole) for a depth of 3.5mm

Now 3D printed holes never have absolute 90 degree shoulders so I need to round off the edge a bit so it will go all the way down into the hole. That's called a fillet. Like smearing body filler along a 90 degree corner or in this case taking a file to the sharp edge and rounding it a tad.

Save the file. Export it as an STL file for the 3D printing format. Print it hole side up so the bottom also has the textured finish of the build plate.

Drop it into the hole. Either some Krazy Glue or Epoxy and the nut under it will remain firmly in place.

And yes, I could have made the knobs out of wood and embedded the nut in a round hole with epoxy and just cut up a piece of dowel as I described above.

Now parametric CAD used to the full extent is way more powerful than what I just did. What that allows is making dimensions dependent on other dimensions. Change one value and it ripples through and changes others. Very handy for some things but not mandatory.

After visiting Slow-poke and seeing all the stuff he printed with his, I was amazed at what could be done with a plastic filament printer. The following week, I decided to look on kijiji for a use one. I found a Prusa mini and I am super happy I bought it. It motivated me to learn cad which I have always wanted to do but did have the opportunity to try it out. I have never done anything other than writing email on a computer. It was a bit of a learning curve but not that bad with lots of Youtube tutorials. I am always mesmerized looking at the little toy printer. In the beginning I would watch it print for quite a while, just couldn't believe what it could do. Yesterday I printed some tube connectors. I must of fondle the part for half an hour in admiration and wondering how did it succeed making such a nice part.

Last edited: