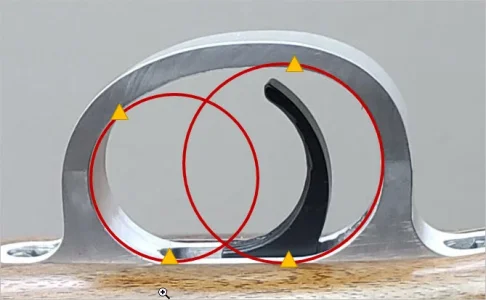

Its probably just photo perspective but using this as example, you could also modify the 2-circle + 2-arc method to create a different shape by altering the relative diameters of horizontal circles but still connect them with a tangent arcs top & bottom. This would give the shape a more wedged aspect ratio in one orientation if that was desireable.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oval, ellipse or something else?

- Thread starter Perry

- Start date

I am in the camp of two different sized modified Circles like the last one and like @thestelster made. I prefer a trigger gaurd with a little asymmetry to it to accomodate a gloved hand. The Remington factory 700 trigger gaurd is a good one in my view.

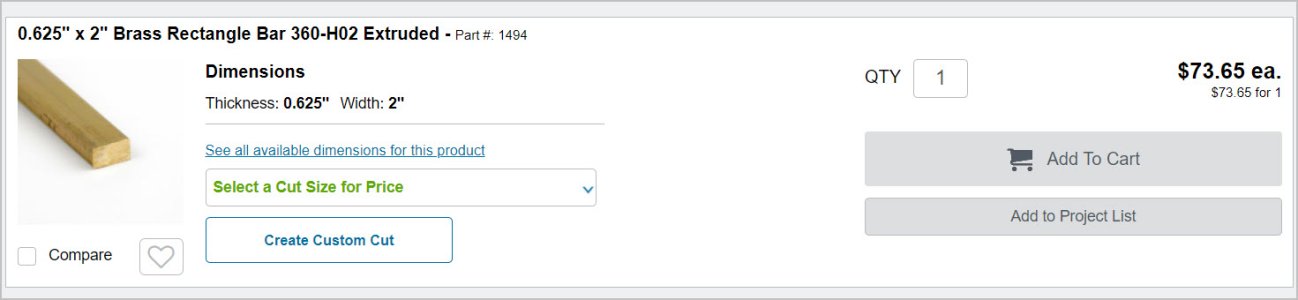

Well the sticker price of $45.00 at Metal Supermarket for a 2"X3.5" X 3/4" (need 5/8") piece of brass has scared my friend off. Project is on hold well he begins the scavenge process.

I had a few old bathroom fixtures in my bin, but just not enough meat where I need it. (Thinking about it now those might be made of bronze.)

I had a few old bathroom fixtures in my bin, but just not enough meat where I need it. (Thinking about it now those might be made of bronze.)

Well the sticker price of $45.00 at Metal Supermarket for a 2"X3.5" X 3/4" (need 5/8") piece of brass has scared my friend off. Project is on hold well he begins the scavenge process.

I had a few old bathroom fixtures in my bin, but just not enough meat where I need it. (Thinking about it now those might be made of bronze.)

I'm sorry. I'm having a little trouble with this one. Your buddy doesn't mind you spending a day or more chasing this all down for him but he thinks 45 bucks for a block of stock is too much?

If I were you, I'd suggest that I'll buy the block for him but he has to make the gaurd himself using a file and a hand drill.

I can never get my head around that mentality. The parts or raw materials are too much money but the value of my work isnt given a second thought.

I'm guessing you really like this character for other reasons.

I'm sorry. I'm having a little trouble with this one. Your buddy doesn't mind you spending a day or more chasing this all down for him but he thinks 45 bucks for a block of stock is too much?

If I were you, I'd suggest that I'll buy the block for him but he has to make the gaurd himself using a file and a hand drill.

I can never get my head around that mentality. The parts or raw materials are too much money but the value of my work isnt given a second thought.

I'm guessing you really like this character for other reasons.

Well the sticker price of $45.00 at Metal Supermarket for a 2"X3.5" X 3/4" (need 5/8") piece of brass has scared my friend off. Project is on hold well he begins the scavenge process.

I had a few old bathroom fixtures in my bin, but just not enough meat where I need it. (Thinking about it now those might be made of bronze.)

I've had similar bizarre conversations at times with potential clients. I always start with can you buy that thing? Then buy it. Machining or custom software projects - same weird conversation. This is going to take me 8 hours to make - how much would you charge for 8 hours time? That gets them thinking. Often though if that is where their head is there is no point in discussing it. People just seem to think getting something done custom just for them should cost about as much or less than buying it in a store.

@Susquatch You said people with broken trigger guards would pay lots for a custom replacement. Above it seems like no they won't. Do you think really they would?

You said people with broken trigger guards would pay lots for a custom replacement. Above it seems like no they won't. Do you think really they would?

I don't think I said that John.

I seem to recall someone else said that though. I just can't find it for you.

In my opinion, the people who might pay for a nice custom one are not people with a broken one. They are fussy people who know exactly what they want and can't find it.

I typically pay 50 bucks for a decent trigger gaurd. But they are hardly custom units.

@SusquatchI've had similar bizarre conversations at times with potential clients. I always start with can you buy that thing? Then buy it. Machining or custom software projects - same weird conversation. This is going to take me 8 hours to make - how much would you charge for 8 hours time? That gets them thinking. Often though if that is where their head is there is no point in discussing it. People just seem to think getting something done custom just for them should cost about as much or less than buying it in a store.

I had a stint working a contractor for a little boutique software consulting shop. The clients were small - a few employees - maybe up to 25 or 50. Every single one cheap as hell. Tell them something is going to take 15-25 hours. And every change you need will add significant hours to the bill. It was mostly a hopeless relationship. Their expectations were sky high and their budget a pittance. Complete mismatch. I've thought about it a lot - we didn't set the right expectations and if we did we didn't get the job.I've had similar bizarre conversations at times with potential clients. I always start with can you buy that thing? Then buy it. Machining or custom software projects - same weird conversation. This is going to take me 8 hours to make - how much would you charge for 8 hours time? That gets them thinking. Often though if that is where their head is there is no point in discussing it. People just seem to think getting something done custom just for them should cost about as much or less than buying it in a store.

@Susquatch You said people with broken trigger guards would pay lots for a custom replacement. Above it seems like no they won't. Do you think really they would?

He is a good guy. One of the reasons I am doing this for free for him. We are worlds apart on disposable income. He did offer to pay me for my effort, but I'm ok with doing it in my spare moments. He is only just realizing the effort it takes to make something. (Like most people that are not in the hobby). He figured a CNC machine would just "MAKE" the part.I'm sorry. I'm having a little trouble with this one. Your buddy doesn't mind you spending a day or more chasing this all down for him but he thinks 45 bucks for a block of stock is too much?

If I were you, I'd suggest that I'll buy the block for him but he has to make the gaurd himself using a file and a hand drill.

I can never get my head around that mentality. The parts or raw materials are too much money but the value of my work isnt given a second thought.

I'm guessing you really like this character for other reasons.

I have ran into many people I would love to give them the material and a dull file ,with a dull drill. lol.

I'm just so busy right now. Still haven't got back to the garage project, but it is nice to have a little project to play with when I have a few minutes here and there. Hopefully by the end of next month life will ease up for me a bit.

Last edited:

@Susquatch You said people with broken trigger guards would pay lots for a custom replacement. Above it seems like no they won't. Do you think really they would?

Oval, ellipse or something else?

I have been asked if I could make up a brass trigger guard to replace a plastic one on an air rifle. Easy peazy. Nope. lol The opening for the trigger area is causing me to think. (more then I'm used to, lol) Google has failed to give me an easy answer of a formula for this shape...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

He is a good guy. One of the reasons I am doing this for free for him. We are worlds apart on disposable income. He did offer to pay me for my effort, but I'm ok with doing it in my spare moments. He is only just realizing the effort it takes to make something. (Like most people that are not in the hobby). He figured a CNC machine would just "MAKE" the part.When I sent him the CAD drawing is when I think he first started to realize the work behind a "one of" type project.

I have ran into many people I would love to give them the material and a dull file and a dull drill. lol.

I'm just so busy right now. Still haven't got back to the garage project, but it is nice to have a little project to play with when I have a few minutes here and there. Hopefully by the end of next month life will eases up for me a bit.

OK, that's kind of what I ended up guessing. You like him so you are just doing it for him.

I do that a lot too. Generally, II don't tell them what the block costs. I just buy it and hope they never ask or if they do I just say I got it cheap.

Some people are just good people worth helping. Cost is not the issue.

I guess what threw me off was him baulking at the cost of the block. Knowing now the situation, I would not have told him.

Want a photo and dimensions of a nice gaurd?

Or maybe want a source to buy one (that you can tell him was cheap)?

I wish I had the time to learn that stuff. I think its so amazing. There are a lot of shooters' rifles out there with broken trigger guards that aren't available anymore who are willing to pay hefty prices for replacements. Keep at it, it looks great.

You have the time. That's not the problem. The problem is that's its not a priority...... LOL!.

Btw, it's not a priority for me either.

He is an older gentlemen. One of his hobbies is air guns. This one gun he has taken a liking to. It is actually a nice gun, but for economic reasons they cheaped out on a few things on it. One is the plastic trigger guard.OK, that's kind of what I ended up guessing. You like him so you are just doing it for him.

I do that a lot too. Generally, II don't tell them what the block costs. I just buy it and hope they never ask or if they do I just say I got it cheap.

Some people are just good people worth helping. Cost is not the issue.

I guess what threw me off was him baulking at the cost of the block. Knowing now the situation, I would not have told him.

Want a photo and dimensions of a nice gaurd?

Or maybe want a source to buy one (that you can tell him was cheap)?

He insisted on paying for the material seeing I was going to do the work for free. I don't think he realized the cost of the material. I should have just grabbed it, now that you mentioned it. When I seen the price, I figured I better run it by him first. (Percentage wise, that is a big amount considering the cost of the air rifle.)

I've got a bunch of aluminum here, but I'm sure he is trying to make that thing sparkle.

Yeah, brass is getting spendy. My spot check is Online metals in States. If I did my math right, works out to ~26 CAD for that length. But that doesn't include shipping dinger dollars & wait time. Probably be pretty close to MSM at the end of it. The sad part is probably 3/4 will be shavings. I try to plan forward a couple months, slowly build an order. Typically I need small quantities of diverse weird stuff. Wait for the 10-15% e-coupon to arrive, hold my nose & click buy.

Attachments

lolhold my nose & click buy

The money someone is willing to spend on a project or custom part is directly proportional to either the value or importance of the whole unit. Someone with a $100.00 air rifle isn't prepared to spend that much money, unless it has sentimental value. My gentleman which I made this trigger guard for has been a long time customer mine. He has given me $20-30 thousand dollars worth of work over the years, so I was willing to do the job, even though I knew I would lose money on the job. Saying that I still charged him $200.00, and told him he would still have to make it look nice by filing and contouring (it's still too blocky), and either painting it or anodizing it, and he was more than happy to do that.

The money someone is willing to spend on a project or custom part is directly proportional to either the value or importance of the whole unit. Someone with a $100.00 air rifle isn't prepared to spend that much money, unless it has sentimental value. My gentleman which I made this trigger guard for has been a long time customer mine. He has given me $20-30 thousand dollars worth of work over the years, so I was willing to do the job, even though I knew I would lose money on the job. Saying that I still charged him $200.00, and told him he would still have to make it look nice by filing and contouring (it's still too blocky), and either painting it or anodizing it, and he was more than happy to do that.

This is the voice of experience speaking...... It lines up nicely with my thoughts on it.

Additional thoughts on this project for the OP - @Perry

A variety of trigger gaurds can be had on Brownells/Sinclair. Midway is a great source too but they won't ship to Canada so you have to have a friend in the USA get it for you. There are also a few places that specialize in parts for oem products.

My point here is that a premade trigger or even an entire floorplate can be had for the same cost as the block and just modified to fit. This is the approach I have always taken and never been disappointed.

A nice block of brass can be had cheap but first you need a forge and a milling machine. Oh damn, there goes cheap. Saw a nice looking AR-15 a guy made, the receiver was milled out of melted down 223 cases he cast into a block then started machining. Likely not even close to the chemical composition of regular brass but it worked fine for 22lr.

This was the route I originally wanted to go. In fact I have 4 or five trigger guards from other firearms, but the screw hole spacing wouldn't work. I did order a "blank" from the US, but it wasn't "blank" enough, and wouldn't work either.This is the voice of experience speaking...... It lines up nicely with my thoughts on it.

Additional thoughts on this project for the OP - @Perry

A variety of trigger gaurds can be had on Brownells/Sinclair. Midway is a great source too but they won't ship to Canada so you have to have a friend in the USA get it for you. There are also a few places that specialize in parts for oem products.

My point here is that a premade trigger or even an entire floorplate can be had for the same cost as the block and just modified to fit. This is the approach I have always taken and never been disappointed.

$200 good for you @thestelster I'm really glad to hear that.The money someone is willing to spend on a project or custom part is directly proportional to either the value or importance of the whole unit. Someone with a $100.00 air rifle isn't prepared to spend that much money, unless it has sentimental value. My gentleman which I made this trigger guard for has been a long time customer mine. He has given me $20-30 thousand dollars worth of work over the years, so I was willing to do the job, even though I knew I would lose money on the job. Saying that I still charged him $200.00, and told him he would still have to make it look nice by filing and contouring (it's still too blocky), and either painting it or anodizing it, and he was more than happy to do that.