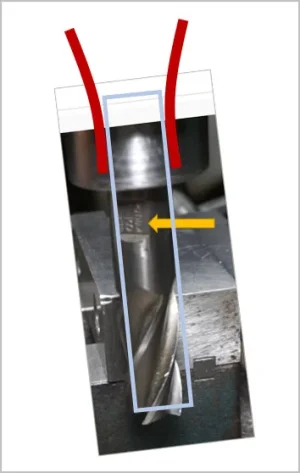

My experience has been the opposite. For the same material removal, roughers put less stress on lighter duty machines & make better use of limited HP so actually more beneficial. I highly recommend them. They make a very efficient chip. Some notesfrom what i understand roughing endmills actually take more hp and rigidity, but maybe that's to take full advantage of the roughing action, im not sure

- they typically make roughers in fine & coarse depending on size. You might want to try one of each to see which you prefer & what your machine likes. In terms of end cutting, they make a pretty decent finish. Sometimes on non-critical parts I don't even bother swapping in a regular EM. Side milling of course leaves little serrations on the part.

- they will be metric on Ali, so hopefully you have an ER or some collet system to accommodate

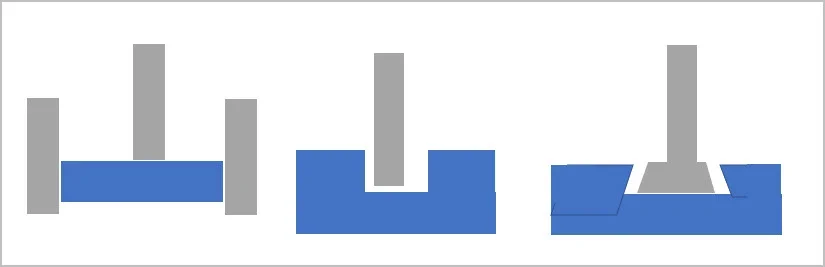

- what I find advantageous is but a rougher same diameter as regular/finishing EM. That way you can hog out your work, leave some allowance, then plop the regular EM in & your dimensions & settings stay mostly the same. I say mostly because all EM's have tolerance. The roughers are a bit more +/-

Do some poking around AliExpress, there's lots of sales & coupons going on now it seems.