-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need to get drill bits for tapping

- Thread starter Warlock

- Start date

Martin w

Ultra Member

The only Canadian manufacturer I know of is Gray Tools. Not sure where they source their drills from. But they have a nice set. Any local industrial supply should be able to set you up.

Myself, I scan Kijiji and Marketplace for used drills. I have complete sets of Huot boxes as well as taper shank up to 2-1/2" all for cheap on Kijiji. It takes time and patience's though.

Then you can jump into the sharpening end and have them all ready to drill.

Martin

Myself, I scan Kijiji and Marketplace for used drills. I have complete sets of Huot boxes as well as taper shank up to 2-1/2" all for cheap on Kijiji. It takes time and patience's though.

Then you can jump into the sharpening end and have them all ready to drill.

Martin

Dan Dubeau

Ultra Member

Don't think there are any Canadian drill manufacturers, but I'd love to be wrong. There might be Canadian importers rebranding quality stuff though.

A good quality 115pc index new is expensive, and only getting more expensive. Scour kijiji and marketplace and be ready to jump on deals when they pop up. If you want one click shopping, and don't mind buying once and crying once, this set is very good quality, and decently priced comparatively to other quality drills.

Alternatively you can buy a cheap index or one missing some drills and buy individual quality drills from KBC or other local industrial supply house in the most frequently used tap/clearance sizes. I did that for my work box years ago, and would just buy a bunch of drills of different sizes to replace the junk ones in my cdn tire index with dormers. Eventually wound up with almost a full index of good ones a little at a time. There's a bunch of sizes in a full index you will most likely never use.

Jobber length, Bright finish 118* HSS will be great all around general purpose bits for 98% of home shop needs.

A good quality 115pc index new is expensive, and only getting more expensive. Scour kijiji and marketplace and be ready to jump on deals when they pop up. If you want one click shopping, and don't mind buying once and crying once, this set is very good quality, and decently priced comparatively to other quality drills.

Alternatively you can buy a cheap index or one missing some drills and buy individual quality drills from KBC or other local industrial supply house in the most frequently used tap/clearance sizes. I did that for my work box years ago, and would just buy a bunch of drills of different sizes to replace the junk ones in my cdn tire index with dormers. Eventually wound up with almost a full index of good ones a little at a time. There's a bunch of sizes in a full index you will most likely never use.

Jobber length, Bright finish 118* HSS will be great all around general purpose bits for 98% of home shop needs.

Last edited:

I went to Sowa tools for what I needed. They have cheap-er and then expensive lines. But they don't try to upsell, they try to sell according to your needs

For the last 20 years or so, I stopped buying cheap drill sets. Now I mostly buy individual Dormer drills as I need them at my local Varco. They do online sales too. My local Varco maintains a full stock of metric, imperial, and numbered drills. I have not had a bad one yet. I believer Dormer drills are made in Brazil.

I did buy a set of lower cost 1/64ths Drill Hogs just recently, but the jury is still out on them.

I did buy a set of lower cost 1/64ths Drill Hogs just recently, but the jury is still out on them.

Thank you all for responding. I think I will buy good individual bits in the hole sizes and tap sizes that I expect I will need the most. Probably cheaper then buying sets where a lot of the bits I will never use.

I did buy a couple of bits from Cardon Tools up in Perth yesterday for tapping of 1/2" and 1/4" bolts in 3/16" steel plate. I did drill and tap eight holes to accept 1/4"-20 bolts and the bit cut through the steel plate like a hot knife in butter.

The steel plate is the base for a small project that I have been working on and off over the winter for a leather embosser. Keep in mind I'm a cheap old geezer and I was NOT going to spend $1000 on something I could build better and cheaper ($150) then the "professional" versions. I 3D designed and printed all the parts and made the necessary changes then I 3D printed a drilling template before starting.

Another example is I needed a leather clicker press. I figured I needed about a 5 ton press for the dies and the cheapest 4 ton was plus $3000. So me being me I converted a new 20 ton cheap Princess Auto hydraulic press ( https://www.princessauto.com/en/20-ton-hydraulic-bottle-jack-shop-press/product/PA0009193798 ) which involved about 20 mods.

I did buy a couple of bits from Cardon Tools up in Perth yesterday for tapping of 1/2" and 1/4" bolts in 3/16" steel plate. I did drill and tap eight holes to accept 1/4"-20 bolts and the bit cut through the steel plate like a hot knife in butter.

The steel plate is the base for a small project that I have been working on and off over the winter for a leather embosser. Keep in mind I'm a cheap old geezer and I was NOT going to spend $1000 on something I could build better and cheaper ($150) then the "professional" versions. I 3D designed and printed all the parts and made the necessary changes then I 3D printed a drilling template before starting.

Another example is I needed a leather clicker press. I figured I needed about a 5 ton press for the dies and the cheapest 4 ton was plus $3000. So me being me I converted a new 20 ton cheap Princess Auto hydraulic press ( https://www.princessauto.com/en/20-ton-hydraulic-bottle-jack-shop-press/product/PA0009193798 ) which involved about 20 mods.

Drills related to fasteners are kind of an evil thing. Back when life was simple I use to have a simple wood block stand with progressive tap sizes & their corresponding tap drill & clearance drill size in a row. It wasn't very extensive, like 2-56 to 1/4-X at the time. But it was convenient because it saved me looking for the drill from my set or grabbing the wrong one. And it confined wear to those particular drills, replace them as required. The idea is still good but lots has changed. Different materials call for different % thread engagement, so that might add a few more drills. Same goes for clearance hole, sometimes you want more or less. Now the tap selection has also grown. Now I rarely use IMP fasteners anymore unless I have to because MET fasteners & tooling are much more predominant & affordable, so that's a different set of drill sizes. You can certainly buy specific drills from any machinery suppliers but gone are the days of inexpensive shipping & low min $ orders.

So depending on what you are doing & where you are shopping, a set might make sense. Have a look at some of the drill tap tables & how that reflects on your work. Sadly, my 20 year old Precision Twist HSS set has gone through the roof cost wise. If tapping was confined to only small stuff, a number/letter set covers a lot of range but there will always be exceptions. Because you will go through the same process when sizing a drill for say a reamed hole. There is no easy answer, only your own application & needs.

For example I bought a stub length numbered set a few years back because I wanted the shorter length specifically & it was on sale. It was made in eastern Europe supplied through KBC. It came with a 135-deg split point whereas my existing set was was the classic 112-deg spiral relief. Well the stubs cut like a dream & opened my eyes to that aspect. So there is another consideration, drills are evolving over time. I've bought some real junk from AliExpress I save for handyman abuse & OTOH have bought some really good stuff for reasonable cost. I think the days of Made in Canada for this stuff ended about 40 years ago but I could be wrong.

So depending on what you are doing & where you are shopping, a set might make sense. Have a look at some of the drill tap tables & how that reflects on your work. Sadly, my 20 year old Precision Twist HSS set has gone through the roof cost wise. If tapping was confined to only small stuff, a number/letter set covers a lot of range but there will always be exceptions. Because you will go through the same process when sizing a drill for say a reamed hole. There is no easy answer, only your own application & needs.

For example I bought a stub length numbered set a few years back because I wanted the shorter length specifically & it was on sale. It was made in eastern Europe supplied through KBC. It came with a 135-deg split point whereas my existing set was was the classic 112-deg spiral relief. Well the stubs cut like a dream & opened my eyes to that aspect. So there is another consideration, drills are evolving over time. I've bought some real junk from AliExpress I save for handyman abuse & OTOH have bought some really good stuff for reasonable cost. I think the days of Made in Canada for this stuff ended about 40 years ago but I could be wrong.

I bought these sets from KBC and they have been excellent.

I have metric, NC and NF

www.kbctools.ca

www.kbctools.ca

I have metric, NC and NF

Results Page 1 :: KBC Tools & Machinery

What shame, we have become too reliant other countries for too many things and the really sad thing is a lot of the companies have out sourced some of their items overseas so it can be difficult to figure out the actual manufacturer.I think the days of Made in Canada for this stuff ended about 40 years ago but I could be wrong.

I figure the drill bits that I probably use the most will be:

Bolt size --------- Drill size

#10-24 --------- 5/32"

1/4" --------- 13/64"

5/16" --------- 17/64"

3/8" -16 --------- 5/16"

3/8" - 24 --------- 21/64"

7/16" -14 --------- 23/64"

7/16" -20 --------- 25/64"

1/2" -29 --------- 29/64"

3mm -------------------------2.5mm

4mm -------------------------3.3mm

5mm -------------------------4.2mm

6mm -------------------------5mm

8mm -------------------------6.8mm

10mm ------------------------8.5mm

Last edited:

The idea is still good but lots has changed. Different materials call for different % thread engagement, so that might add a few more drills.

I agree with this totally! I almost NEVER have one drill size for a given tap. Instead, I pick the drill size closest to delivering the clearances I want for the material and application I am tapping.

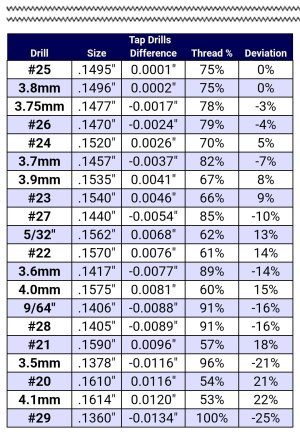

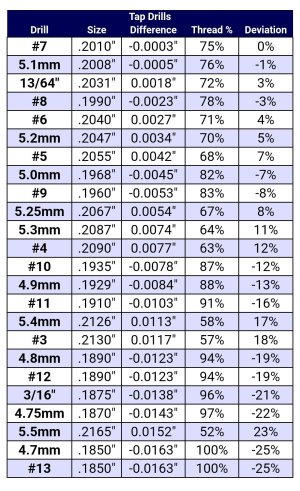

@Warlock - I wasn't really going to say anything about anything till I saw your chart. I've picked two threads from it and added some comments for you. If you have an android phone, install the app called "Tap and Drill Chart Calculator". It will open your eyes about the idea of a standard drill for each tap.

Bolt size --------- Drill size

#10-24 --------- 5/32"

It's the first in your list. So let's focus in on that. Assuming mild steel or aluminium, here are the fits for that particular thread.

Note that your choice of 5/32 provides a 62% thread fit. 62% is fine for most applications, but 75% is usually better. A 75% fit is better accomplished with a #25 or 3.8mm drill. If you want a bit more thread engagement at say 80%, you could choose a #26 or even a 3.6mm at 89%.

Similarly, you chose a 13/64 drill for a 1/4-20 tap.

Tap and drill chart above says that 13/64 drill yields a 72% fit which isn't bad. But a #7 will yield 75%, a number 8 will deliver 78% and a #11 will give you 91%.

The point I am making is the same as Peter T's. You need to know what you are trying accomplish and what will do what. The days of a simple tap and drill combo are long gone.

I sometimes also find I need a looser fit for some reason. Perhaps as low as 50% or even less.

This is why I don't maintain matching tap and drill sets. I figure out what I want and why, and then I go buy that drill for that job.

That's what Sowa made up for me. No looking at charts just drill then tap, even I can't get it wrong 😛

@Susquatch I do appreciate the information but at the moment I'm mostly drilling and tapping holes in flat plate by

i) cutting lengths off threaded rod to make studs

ii) installing the home made stud so it almost goes to the other side of the steel plate

iii) tightening down a nut to over the stud to the steel plate

iv) welding the nut to the steel plate to give a wider base to the stud

v) welding the stud to the nut and in from the other side to fill the hole to add extra strength

i) cutting lengths off threaded rod to make studs

ii) installing the home made stud so it almost goes to the other side of the steel plate

iii) tightening down a nut to over the stud to the steel plate

iv) welding the nut to the steel plate to give a wider base to the stud

v) welding the stud to the nut and in from the other side to fill the hole to add extra strength

I like that do you have a link to their website?That's what Sowa made up for me. No looking at charts just drill then tap, even I can't get it wrong

I don't, sorry@Susquatch I do appreciate the information but at the moment I'm mostly drilling and tapping holes in flat plate by

i) cutting lengths off threaded rod to make studs

ii) installing the home made stud so it almost goes to the other side of the steel plate

iii) tightening down a nut to over the stud to the steel plate

iv) welding the nut to the steel plate to give a wider base to the stud

v) welding the stud to the nut and in from the other side to fill the hole to add extra strength

I like that do you have a link to their website?

I like that do you have a link to their website?

Here you go

Tap & Drill Sets - Tap Sets & Die Sets

Tap & Drill Sets, • Brand: Sowa Taps<br>• Tap Thread Size (Inch): 6-32, 8-32, 10-24, 1/4"-20, 5/16"-18, 3/8"-16, 7/16"-14,1/2-13<br>• Drill Material: High Speed Steel<br>• Drill Size: #36, #29, #7, F, 5/16", U, 27/64Tap & Drill SetsTap Sets & Die Sets

@Susquatch Thank you.

i) cutting lengths off threaded rod to make studs

ii) installing the home made stud so it almost goes to the other side of the steel plate

iii) tightening down a nut to over the stud to the steel plate

iv) welding the nut to the steel plate to give a wider base to the stud

v) welding the stud to the nut and in from the other side to fill the hole to add extra strength

Your example is a great opportunity to discuss alternative drilling. You are using nuts and welding both sides of the connection. In this case, you probably don't even need a threaded hole at all!

I'm not trying to get you to do something you don't want to do. Just presenting a reason why tapping charts exist.

For the sake of discussion, let's just say you need a threaded hole for other reasons - perhaps an adjustment for depth prior to welding.

I assume a mild steel plate. If I were doing that, I would upsize the drill to a 50% thread engagement - maybe even less. The idea being that very few people enjoy tapping manually. At 50% or less, tapping is WAAAAY easier than at 75%. You could probably just use a power drill, a drill press, or your mill to do all the tapping without a tapping head! Zing zing done! I'd also select a gun tap to shoot the cuttings out the other side of the hole.

Have you ever broken a tap off in a hole? That becomes infinitely less likely at 50%.

By the way, I noticed that SOWA includes their yellow ring gun taps in those sets of theirs. Those are REALLY NICE taps!

You have managed to peak my curiosity! What in the world are you making anyhow?

historicalarms

Ultra Member

I agree with this 100% I also often change my drill size because of the quality of the tap I will be using and what the material used will be...some taps can handle full thread bite and some wont !!I agree with this totally! I almost NEVER have one drill size for a given tap. Instead, I pick the drill size closest to delivering the clearances I want for the material and application I am tapping.

slow-poke

Ultra Member

A while back I went a tad drill bit crazy. While searching for a good 115 piece set on eBay I found a set that was listed in another category but appeared to be unused, old and definitely made in USA and priced IIRC $100, with low shipping, so I rolled the dice and it turned out to be a high quality set.

Then I did some organizing......

Thread 'Organized my drill bits'

https://canadianhobbymetalworkers.com/threads/organized-my-drill-bits.14370/

Then I did some organizing......

Thread 'Organized my drill bits'

https://canadianhobbymetalworkers.com/threads/organized-my-drill-bits.14370/