darrin1200

Darrin

I just got this for a great price in a local auction. $50.

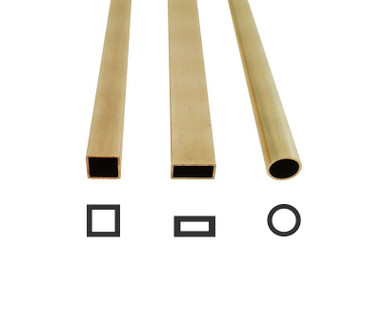

Slick and smooth operating. Needs a little wax on the wood base. Unfortunately, it did not come with the operating key. I figure I should be able to find something on Amazon, but I don’t know the proper name for a key if this type. It’s a 3/16” square piece set inside a 3/8” hole. The hole in the center of the square doesn’t appear to be for anything.

Any help in finding out what it’s called, would be greatly appreciated.

And if I am out to lunch in my understand of this, let me know that too. This is my first vice of this type.

Slick and smooth operating. Needs a little wax on the wood base. Unfortunately, it did not come with the operating key. I figure I should be able to find something on Amazon, but I don’t know the proper name for a key if this type. It’s a 3/16” square piece set inside a 3/8” hole. The hole in the center of the square doesn’t appear to be for anything.

Any help in finding out what it’s called, would be greatly appreciated.

And if I am out to lunch in my understand of this, let me know that too. This is my first vice of this type.