SightlessSeer

Super User

I don't have any pictures to share at the moment, but I have largely finished the new cross slide gib. I still need to mill the dimples for the gib screws to register into and mill the 60° relief into the long edge of the gib. I also picked up some 2BA screws which I proceeded to modify into proper gib screws instead of my jerry rigged gib screws (did it matter? No. Am I happier now that it's right? Yes).

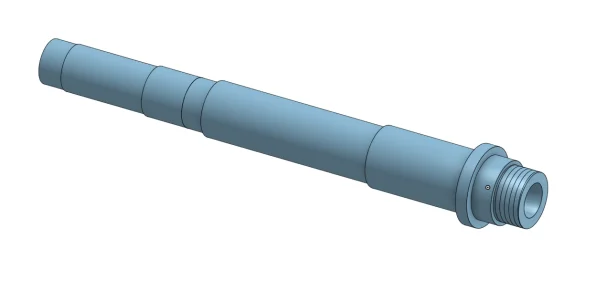

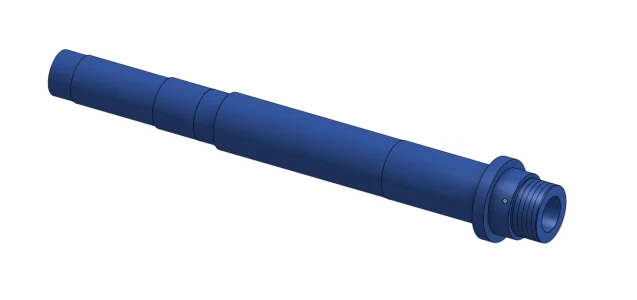

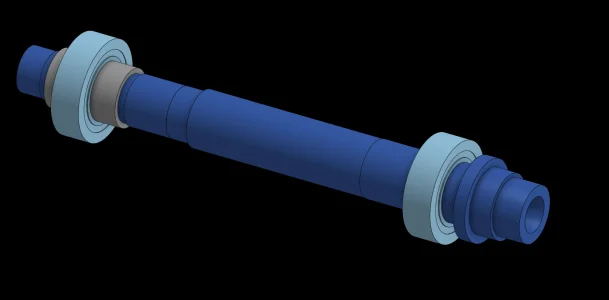

After some further investigation, I found that my head stock casting is different from the one that Wolfgang from this thread used. The distance between the bearing cap bolts is narrower than the casting that he had. As such, if I'm going to convert to roller bearings for the spindle I'm going to have to come up with my own modification instead of blindly following his. Too bad.

I'll make a bigger post when I have more progress to report, but at the moment I'm trying to figure out how I'm going to fixture the gib to cut the relief angles into it. The easiest approach is probably some sacrificial bolts and round stock to push it into the dovetail of the cross slide, but we'll see what I come up with.

After some further investigation, I found that my head stock casting is different from the one that Wolfgang from this thread used. The distance between the bearing cap bolts is narrower than the casting that he had. As such, if I'm going to convert to roller bearings for the spindle I'm going to have to come up with my own modification instead of blindly following his. Too bad.

I'll make a bigger post when I have more progress to report, but at the moment I'm trying to figure out how I'm going to fixture the gib to cut the relief angles into it. The easiest approach is probably some sacrificial bolts and round stock to push it into the dovetail of the cross slide, but we'll see what I come up with.