Was the milling all manual? Or Power Feed? Or full CNC?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My reiden Lathe Fast Tool Rest, Add Some Boxes (2021.06)

- Thread starter a smile

- Start date

a smile

Lifelong hobby - cold iron

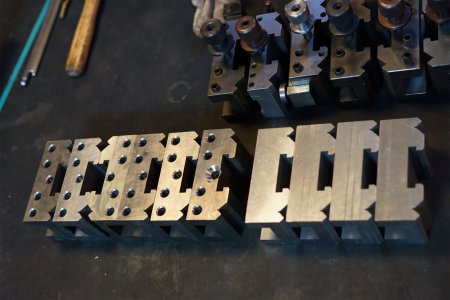

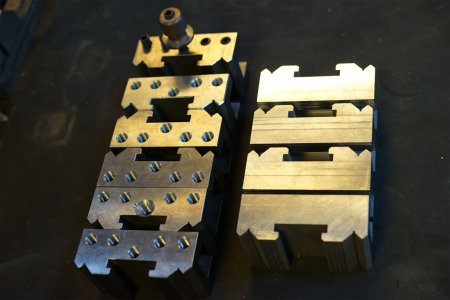

I have tried both manual and electric CNC, but it is a little strange. It can only use simple programming, such as punching holes. I chose to peck holes for programming, and then do other programming. Besides, I was not familiar with the characteristics of metal and cutting tools, so the process was a little difficult, but it was finally completed.

a smile

Lifelong hobby - cold iron

I remeasured it 3 hours ago and confirmed that the distance was 99.70mm, which made it very strange. Does it distinguish between the Asian and American versions?99.70mm divided by 25.4 mm/ inch = 3.92519 inches. It does not make sense in imperial either. Did you guys measure the tool holder or the tool post?

86.67+112.69=199.36mm/2=99.68mm,So 99.70 is an accurate number, we are all confused, I hope the friends who have this tool holder to measure it, so that an accurate and correct number can be retained!

historicalarms

Ultra Member

Forgive me for being inquisitive here....but what is better on these blocks than a simple internal dovetail cut on an inexpensive tool mount. It seems here that you are making 8 or more precession cuts to produce exact angles to mesh together the same as a dovetail holder does with 2 cuts with a "set-in-stone" angle cutter??

It looks to me that the dovetail holder is anchored on 4 unmovable faces so the six that these holders ride on can't be any more than 'equal" in usage.

It looks to me that the dovetail holder is anchored on 4 unmovable faces so the six that these holders ride on can't be any more than 'equal" in usage.

RobinHood

Ultra Member

@a smile , you obviously measured correctly - I was not doubting your measurement.

You did the right thing: make your tool holders to fit your tool post exactly. So well done.

Possibly it is the Swiss made their tool post slightly different so that one has to buy THEIR tool holders as nothing else will fit (unless you make your own).

You did the right thing: make your tool holders to fit your tool post exactly. So well done.

Possibly it is the Swiss made their tool post slightly different so that one has to buy THEIR tool holders as nothing else will fit (unless you make your own).

RobinHood

Ultra Member

Forgive me for being inquisitive here....but what is better on these blocks than a simple internal dovetail cut on an inexpensive tool mount. It seems here that you are making 8 or more precession cuts to produce exact angles to mesh together the same as a dovetail holder does with 2 cuts with a "set-in-stone" angle cutter??

You have a valid point. I think these tool post/holders were designed at a time when precision trumped, cost was never considered and skilled, manual, workers were plentiful and cheap.

The “offshore”, “cheap” products country was Japan.

That changed when Taiwan and later China became the dominant “cheap” products supplier.

The market demanded affordable tool posts and the simple dove tail post was created. Does it work - for sure. Is it as accurate as a wedge style, a double V (like a Dickson) or a multi fix? Not likely. (I may have just put my foot in my mouth with this statement… see below…).

I believe @Dabbler is going to run a comparison experiment of the different styles of tool posts at some point. He can report on his findings when the time comes (and prove me wrong?)

@a smile Nicely done - never did I doubt you either. I just remeasured my holders and got 100.00mm between the centres of the veeways. I may well be just differences in manufacture and standards as all the 'real' Dickson tool posts re in even imperial units...

While @RobinHood above description is 100%, I'd like to add a few thoughts. On the Dickson, the veeways are always at the outside edges of a solid block of steel. So for a given lathe size the veeways are a lot wider than the Aloris style tool holder. Wider means more stable, similar to a tripod. For the same clamping force, there will be far less chance to yaw (the tool dropping down).

Another factor is the height adjuster. On the Aloris style, the adjustment is held purely by the stud and nut. On the Dickson, the height is held by the locking flange, which places it right against the adjuster stud and nut, making the height adjuster more stable, too.

On the Dickson, there are only 4 critical faces, as opposed to 2 in the dovetail style. The T slot can easily be +/- .004 and it won't change anything.

These things are probably nits to pick. Is the Aloris style adequate? Certainly. Is Dickson better? Maybe? Marginally? Who actually knows? I have found my 4-way tool holders to be far more stable in parting off and using form tools than a correctly sized Aloris tool post,

I will be testing them on a test jig so that anyone can reproduce my jig, tests and results. Since @RobinHood let the cat out of the bag 😛 I'm mentioning it here. I planned to make the first round of tests before going public!!

The jig and dimensions for testing was about 50% done when winter hit and things slowed down. Stay Tuned.

Forgive me for being inquisitive here....but what is better on these blocks than a simple internal dovetail cut on an inexpensive tool mount.

While @RobinHood above description is 100%, I'd like to add a few thoughts. On the Dickson, the veeways are always at the outside edges of a solid block of steel. So for a given lathe size the veeways are a lot wider than the Aloris style tool holder. Wider means more stable, similar to a tripod. For the same clamping force, there will be far less chance to yaw (the tool dropping down).

Another factor is the height adjuster. On the Aloris style, the adjustment is held purely by the stud and nut. On the Dickson, the height is held by the locking flange, which places it right against the adjuster stud and nut, making the height adjuster more stable, too.

On the Dickson, there are only 4 critical faces, as opposed to 2 in the dovetail style. The T slot can easily be +/- .004 and it won't change anything.

These things are probably nits to pick. Is the Aloris style adequate? Certainly. Is Dickson better? Maybe? Marginally? Who actually knows? I have found my 4-way tool holders to be far more stable in parting off and using form tools than a correctly sized Aloris tool post,

That's why I'm building a test jig to test all my tool posts. I have American Rocker, Aloris, offshore clones of Aloris, 4-way in 3 sizes, and A Dickson (Rapide). I have managed to arrange the borrow of a real Multifix tool holder for testing as well. I'll be limiting my test to deflection only In the vertical and horizontal directions of a typical tool overhang.I believe @Dabbler is going to run a comparison experiment of the different styles of tool posts at some point. He can report on his findings when the time comes (and prove me wrong?)

I will be testing them on a test jig so that anyone can reproduce my jig, tests and results. Since @RobinHood let the cat out of the bag 😛 I'm mentioning it here. I planned to make the first round of tests before going public!!

The jig and dimensions for testing was about 50% done when winter hit and things slowed down. Stay Tuned.

Stay Tuned.

I will! And I can't wait to see the results. No pressure. 😉

Consider some real world - worst case parting tests too! Absolute measurements of deflection are extremely valuable, but it would be good to be able to correlate that to cutting experience if it is possible.

Each cross slide has different deflection, but I'll try to figure out some kind of real-world test. Trouble is, not all my tool posts will fit on any given lathe. A conundrum. I guess I can use the big one, and make an adapter for smaller tool posts.... Hmmmm...but it would be good to be able to correlate that to cutting experience if it is possible.

Each cross slide has different deflection, but I'll try to figure out some kind of real-world test. Trouble is, not all my tool posts will fit on any given lathe. A conundrum. I guess I can use the big one, and make an adapter for smaller tool posts.... Hmmmm...

That seems like a lot of trouble. I didn't even think that we were talking different lathes here. That was a dumb oversight on my part. I certainly didn't intend to suggest that much work.

My primary intent was to try to correlate deflection numbers to capability in some way that would be meaningful to other members and I. Generally, I think parting is kinda the meat in the sandwich.

If that can't be done, then it can't be done. I should have thought about it a bit more before I suggested it.

No don't feel that way -- Deflection numbers might be interesting from a theoretical point of view, but It still has to relate in some way to a practical use. I'm just curious about what I *think* is going on, and can make a prediction of rigidity. Test world numbers will tell me if I'm wrong in some way! Real world use is something that can surprise you...I should have thought about it a bit more before I suggested it.

So I think it is a good idea to confirm that the deflection numbers actually tell us *anything*...

Last edited:

a smile

Lifelong hobby - cold iron

My own opinion: the locking direction of the dovetail is jacking, which is opposite to the direction of the cutting force. When the cutting force is a lot, there must be a small amount of displacement, because there is enough displacement space.Forgive me for being inquisitive here....but what is better on these blocks than a simple internal dovetail cut on an inexpensive tool mount. It seems here that you are making 8 or more precession cuts to produce exact angles to mesh together the same as a dovetail holder does with 2 cuts with a "set-in-stone" angle cutter??

It looks to me that the dovetail holder is anchored on 4 unmovable faces so the six that these holders ride on can't be any more than 'equal" in usage.

All four faces of the V slot are fitted to the tool post, and with the direction of tension, there should be no change in the position of the tool tip except for the amount of microscopic deformation of the metal.

a smile

Lifelong hobby - cold iron

May I ask you a question? Regarding the price of the knife holder, if you want to get a 125 model knife holder, about how much will it cost in Canadian dollars? And then the second question is what's the highest price you're willing to pay?Mine is a Rapide model. I measured the width across 2 1/2" dowel pins - they are +/- .0005. After subtracting the pin width it was 100.00 mm. But now that you have mentioned it, I will recheck it again to be 100% sure.

I have recently purchased some more metal blocks and plan to re-make some 125mm knife holders, if the price can make some profit, I may consider making some to sell.

Although this is not in line with the purpose of DIY, it will improve my hands-on production ability. Thank you for your previous detailed reply!

Last edited:

if you want to get a 125 model knife holder, about how much will it cost in Canadian dollars?

Several Rapide Dixon style tool posts have come up in the last 3 months in Canada, one of them was 125mm between centres. The post and holders were about 350 CDN$. Another was 300$ and falling - but I think that was 100mm between veeways.And then the second question is what's the highest price you're willing to pay?

For a tool post in good condition with 4 holders in the larger D size - like the one @RobinHood has on his bigger lathe (around 120mm across veeways) I think 400-500 CDN$ is maximum.

Any higher than that and I'd consider the offshore clones at about 500-600 CDN$ for new stock. I've seen the 100mm ones go for around 400$ new, with 2 toolholders.

Anything less than these prices is a good deal, if in good undamaged condition.

Last edited:

a smile

Lifelong hobby - cold iron

Attachments

a smile

Lifelong hobby - cold iron

Now I can finish the processing in about 15 hours, but sometimes the EDM will have some strange faults, resulting in me wasting time and increasing the waste of molybdenum wire, sometimes it may take more than 20 hours.Sun - How long does it take the EDM to make one of those cuts? Cool parts for sure.

The combination of a beat-up EDM and a completely novice operator is a bad collaboration!

Perhaps for a skilled operator + a qualified equipment, the estimated normal processing time should be about 10 hours, or less!

I am getting familiar with the operation and also repairing the EDM. After the test works properly, I will make several products and sell it as commodities!

@kevin.decelles you have a home made EDM you have been working on. Could it make cuts like Sun is doing above?