CrusherDestroyer

New Member

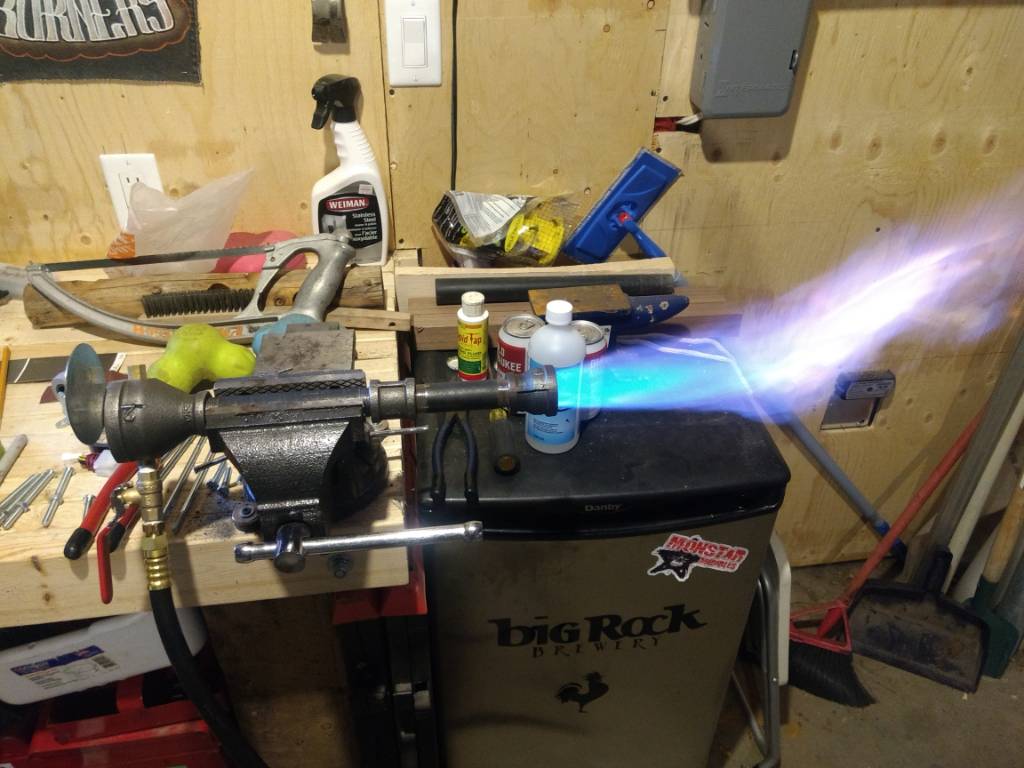

Hi all,

I posted a video on YouTube showing off my forge and I need some advice. The description in the video comments says it all. Any help would be appreciated. Thanks.

Sent from my XT1635-02 using Tapatalk

I posted a video on YouTube showing off my forge and I need some advice. The description in the video comments says it all. Any help would be appreciated. Thanks.

Sent from my XT1635-02 using Tapatalk