After asking about casting Al, I am wondering what some of you use to check the temp of your melt? I have an IR temp gun that I used in the auto repair business, but it doesn't go nearly high enough for casting. Or do you just melt it and pour? If there was something reasonably priced I would be interested. I hate not knowing what I'm doing, although that is becoming more frequent as the yrs. go by. HAHA

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

molten metal temp

- Thread starter garageguy

- Start date

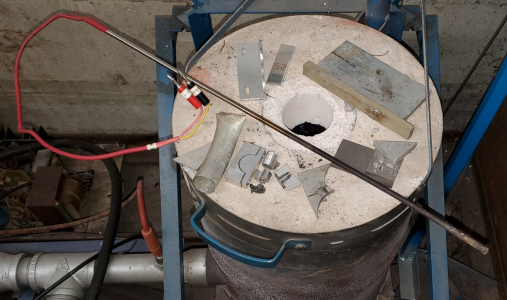

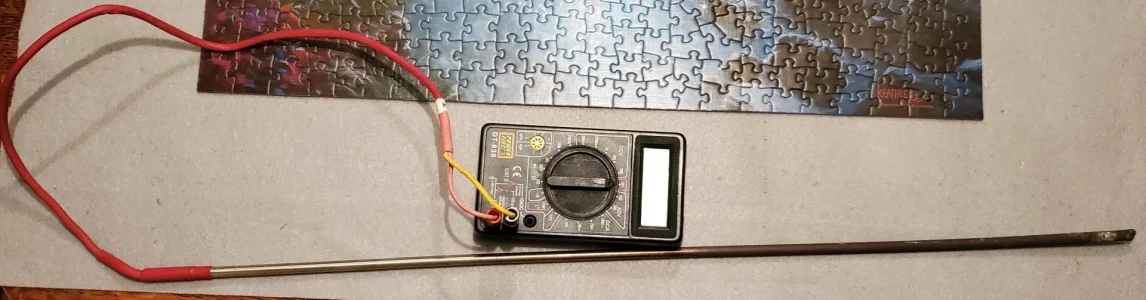

I bought this cheap little meter from Princess Auto. It has a K Type Thermocouple input. The probe was made for my by the late Robert Grauman in Edmonton. The tube is stainless steel. The Thermocouple joint is welded into the tip. High temperature insulated sleeves I believe inside. The probe and wire are long enough that I don't have to be right over the crucible to measure the temperature.

BTW, in case anyone is wonder what "Pour under 0.5" etc. means it has to do with the thickness of the pattern being cast. Thin castings require higher temperature since it can cool too fast, chill and block flow to the rest of the pattern. Thicker patterns require cooler temperatures otherwise the metal shrinks too much as it cools and the top of the castings have dips. If that makes sense.Oh and here's the temperature chart I have hanging by the furnace.

View attachment 45574

I have the same PA Meter (used to go on Sale for around $10), made my own Probe by the simple act of pinching the supplied thermocouple in the end of some stainless pipe, and running a weld bead across the end. Thermocouples, are marvelously forgiving things, as long as you have the two wires fused into the end of the probe, you will get the correct results! If you dig through the correct suppliers catalogs, you can find sources for the various thermocouple wires, and the ceramic beads that might be used to keep them separate in the probe, as well as a great number of very much more expensive, (but not necessarily better) pre-built units.I bought this cheap little meter from Princess Auto. It has a K Type Thermocouple input. The probe was made for my by the late Robert Grauman in Edmonton. The tube is stainless steel. The Thermocouple joint is welded into the tip. High temperature insulated sleeves I believe inside. The probe and wire are long enough that I don't have to be right over the crucible to measure the temperature.

View attachment 45573

I'll add that Rob G was a very good and dear friend, pretty near tireless in sharing anything he knew, to anyone that was interested, and I hold that as a pretty high bar to meet! He and Rupert Wenig, taught me a LOT about casting! And a lot of other related skills, like making furnace burners, how to prevent, or troubleshoot casting flaws, and a bunch more.

Robert was kind enough to leave to me his entire library of technical related books, among other gifts. I miss him! But I am glad to have known him, at least the parts I did.

Tobho Mott

Well-Known Member

I'm a year late to this party, but I really like mine, built mine similar to Henry Davis AKA HT1 metalworks', using a MIFCO replacement thermocouple tip that needs no protective sheath. I know some guys on the home foundry forums forums who instead buy cheaper probes then make or buy graphite sheaths to protect them, which is another great option.

Here's HT1's pyrometer video:

Jeff

Here's HT1's pyrometer video:

Jeff

I made a similar setup using a cheap handheld thermocouple reader <$40 and the temperature probe (Mifco type) I got from Foundry Supply Source (used to be Smelko). I'll find a picture of the "temporary prototype" that became permanent.I'm a year late to this party, but I really like mine, built mine similar to Henry Davis AKA HT1 metalworks', using a MIFCO replacement thermocouple tip that needs no protective sheath. I know some guys on the home foundry forums forums who instead buy cheaper probes then make or buy graphite sheaths to protect them, which is another great option.

Here's HT1's pyrometer video:

Jeff

Tobho Mott

Well-Known Member

I must admit I don't use mine as often as I probably should. I tend to rely on the 'poor man's pyrometer' - dip a preheated steel rod in the melt then see how much (if any) sticks to it, to judge whether pouring temperature has been reached, as well as other clues like what colour of hot it's glowing. That works pretty well for me, most of the time.

Sometimes I worry I'm going to overheat my melt futzing around trying to get a good reading off my immersion pyrometer and cause worse problems than I was trying to avoid, but I'm sure that is really just due to my lack of practice actually using it.

If I did more production type work, it would make sense to use it to try and dial in ideal pouring temps for specific patterns, but just about everything coming through here to date is all one or two-offs, where there will never be enough iterations and rarely any real need to accomplish that. The only time I really did any sort of production casting was 3 years ago when I made a 77 casting run of flask sides and molding tools for a local blacksmithing school. (7 sets of 8 flask sides plus a rammer, a rapper, and a strike)

But even then the castings only had minimal machining (flask sides only), and none of them would be impacted by a little bit of internal porosity due to an overheated melt, and if it was overheated badly enough to cause shrink, the way I molded and fed them it would only have added a bit of beneficial sand retention texture to the interior surfaces of the flask sides.

I'll be doing the 4.5h road trip to Milton next Friday to pick up a load of silica, bentonites, sea coal and ferrosilicon for an upgrade/project that's been a long time coming. Looking forward to seeing their new location, I've had stuff shipped before since the switch-over, and talked friends living in Guelph and planning visits with family living here to do a couple of small pickups for me, but I haven't been there in person since 2015 when then-owner Tim Smelko took an hour out of his day to give me the most amazing tour (while my 8yo son sat in the office and played with the paper shredder)

Sorry for rambling, I've wandered way off pyrometers. Cutting myself off here.

Jeff

Sometimes I worry I'm going to overheat my melt futzing around trying to get a good reading off my immersion pyrometer and cause worse problems than I was trying to avoid, but I'm sure that is really just due to my lack of practice actually using it.

If I did more production type work, it would make sense to use it to try and dial in ideal pouring temps for specific patterns, but just about everything coming through here to date is all one or two-offs, where there will never be enough iterations and rarely any real need to accomplish that. The only time I really did any sort of production casting was 3 years ago when I made a 77 casting run of flask sides and molding tools for a local blacksmithing school. (7 sets of 8 flask sides plus a rammer, a rapper, and a strike)

But even then the castings only had minimal machining (flask sides only), and none of them would be impacted by a little bit of internal porosity due to an overheated melt, and if it was overheated badly enough to cause shrink, the way I molded and fed them it would only have added a bit of beneficial sand retention texture to the interior surfaces of the flask sides.

I'll be doing the 4.5h road trip to Milton next Friday to pick up a load of silica, bentonites, sea coal and ferrosilicon for an upgrade/project that's been a long time coming. Looking forward to seeing their new location, I've had stuff shipped before since the switch-over, and talked friends living in Guelph and planning visits with family living here to do a couple of small pickups for me, but I haven't been there in person since 2015 when then-owner Tim Smelko took an hour out of his day to give me the most amazing tour (while my 8yo son sat in the office and played with the paper shredder)

Sorry for rambling, I've wandered way off pyrometers. Cutting myself off here.

Jeff

Tobho Mott

Well-Known Member

Not sure yet, still waiting to hear some of the details and receive a final quote. I'll report back when I know moreWhat sizes does the ferrosilion come in and what do they want for it?

Jeff

ChazzC

Ultra Member

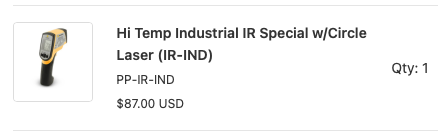

UPDATE: I don't know what the list price of my IR-IND was late last year, but this is what it was on Super-Duper/Special/Black Friday Sale:My ThermoWorks IR-IND goes up to 1400F, and their IR-PRO goes to 1832F; not cheap (US$174 & US$239, respectively; got mine on Black Friday last year for much less).

I know: I SUCK!

Curious if you've tried it and possibly compared the readings with an immersion type? Everything I've read thus far indicates IR guns will not give you the temperature of the melt...an actual comparison and knowing would beat guessing. I use one of these with off the shelf K probes for aluminum.

Edit: Thanks for sharing that chart John. A handy little thing to have nearby. 🙂

Edit: Thanks for sharing that chart John. A handy little thing to have nearby. 🙂

Proster Digital Thermocouple Thermometer Dual Channel Temperature Meter Tester with Two K Type Thermocouple Probe Sensor and LCD Backlight for K/J/T/E/R/S/N Type (Red) : Amazon.ca: Industrial & Scientific

Proster Digital Thermocouple Thermometer Dual Channel Temperature Meter Tester with Two K Type Thermocouple Probe Sensor and LCD Backlight for K/J/T/E/R/S/N Type (Red) : Amazon.ca: Industrial & Scientific

www.amazon.ca

ChazzC

Ultra Member

I checked it against a surface thermocouple at “normal” temperatures back when it arrived, but haven’t tried it on elevated temps yet (I got it primarily for checking things in the toaster oven). However, there’s no reason to think it wouldn’t give good results up to the rated temperature: you would need to adjust the emissivity for each metal to calibrate it.Curious if you've tried it and possibly compared the readings with an immersion type? Everything I've read thus far indicates IR guns will not give you the temperature of the melt...an actual comparison and knowing would beat guessing. I use one of these with off the shelf K probes for aluminum.