DanCom

New Member

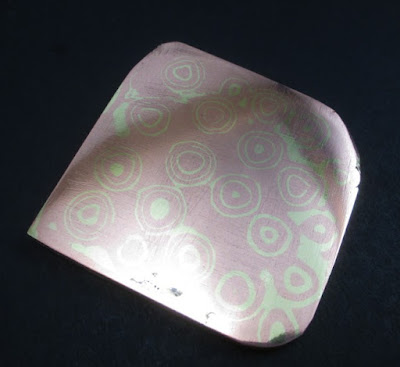

Ok, so I've never done this before, but certainly did lots of reading and asked some questions on this forum (Thanks Tim). Here's my evening of making mokume gane with copper and brass sheet.

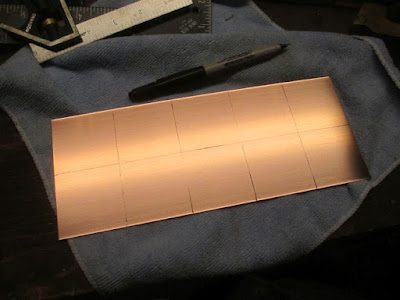

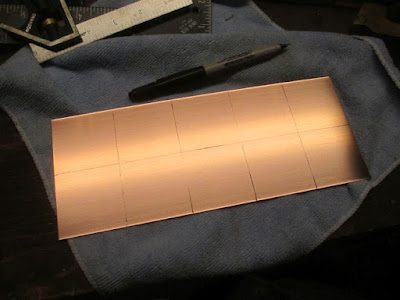

I started with one sheet of copper and one sheet of brass. Nice and clean.

This was overpriced at the hobby store, but I figured it was saving me the the scrubbing.

These sheets are 4 x 10" which should make five 2"x2" pieces per per sheet.

The copper is a little thicker than the brass, but we'll live with it.

With a ruler or square and a permanent marker, layout the 2" squares.

Do this for both the brass and copper sheets.

You can probably cut this with some snips, but I choose the porta-bandsaw,

Same 2" square pieces for the brass.

Here I am holding a nice stack of alternating copper & brass plates.

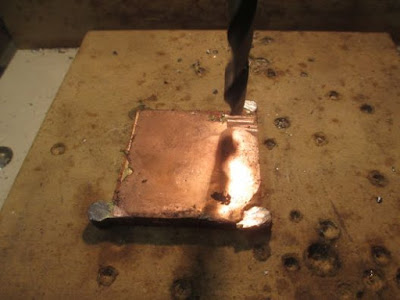

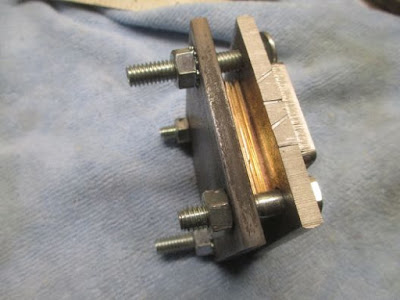

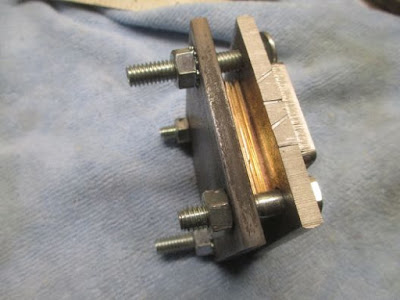

I squeeze them into my handy compression plate thingy.

It's really two pieces of 1/4" plate with four 5/16" bolts to squish the copper and brass.

Clamps also work, but whatever you use has to fit into the forge for heating.

As per Tim's suggestion, I got some Borax. No, not that crazy comedian from Sloblazekhstan, but rather a trip to the Walmart in the laundry isle.

I mixed a small amount of Borax (3 teaspoons) with a smaller amount of water to make a paste.

With the brush I applied the paste Borax to the perimeter of the stack. All the way around. Covering everything in the cracks.

On one of the longer bolts I fitted some scrap steel and a nut for a handle and tossed her in the forge.

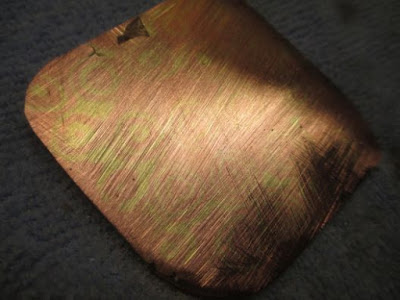

Once in the forge, watch. Turn like a hot dog. Even heat through the billet is the aim.

Now the whole thing is glowing yellow, pull the billet before the brass melts and leaks all over.

(personal experience).

2 B Cont'd...

I started with one sheet of copper and one sheet of brass. Nice and clean.

This was overpriced at the hobby store, but I figured it was saving me the the scrubbing.

These sheets are 4 x 10" which should make five 2"x2" pieces per per sheet.

The copper is a little thicker than the brass, but we'll live with it.

With a ruler or square and a permanent marker, layout the 2" squares.

Do this for both the brass and copper sheets.

You can probably cut this with some snips, but I choose the porta-bandsaw,

Same 2" square pieces for the brass.

Here I am holding a nice stack of alternating copper & brass plates.

I squeeze them into my handy compression plate thingy.

It's really two pieces of 1/4" plate with four 5/16" bolts to squish the copper and brass.

Clamps also work, but whatever you use has to fit into the forge for heating.

As per Tim's suggestion, I got some Borax. No, not that crazy comedian from Sloblazekhstan, but rather a trip to the Walmart in the laundry isle.

I mixed a small amount of Borax (3 teaspoons) with a smaller amount of water to make a paste.

With the brush I applied the paste Borax to the perimeter of the stack. All the way around. Covering everything in the cracks.

On one of the longer bolts I fitted some scrap steel and a nut for a handle and tossed her in the forge.

Once in the forge, watch. Turn like a hot dog. Even heat through the billet is the aim.

Now the whole thing is glowing yellow, pull the billet before the brass melts and leaks all over.

(personal experience).

2 B Cont'd...