As above suggestions, the basics are

- Material: some steels just cut crappy. Hot rolled is a tad better than cold rolled but neither are exactly wonderful in plain grades when you get right down to it. Try to get hold of some 12L14 (leaded) steel just to try. Its not actually that much more expensive. Should cut shiny nice like brass or aluminum. If you cant make a nice finish on that, there is something else to chase down

- Machine rigidity: generally smaller machines flex a bit more so you might have to take lighter depth cuts & slower traverse speed. But I've seen some real nice steel results on little Sherlines & Taigs. Ensure everything is clamped down rigidly. Try & obey tailstock usage if protruding amount is (what is it now... 2-3 times diameter?). Some guys bolt their lathes to spongy plywood bases or non-solid wood which can loosen up over time. Heavier cuts & more power will put more demand on rigidity.

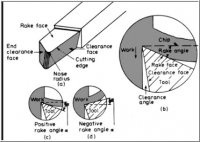

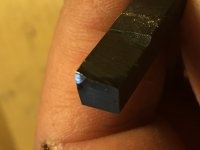

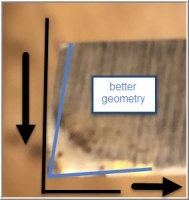

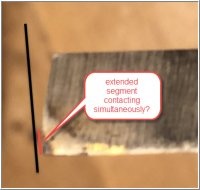

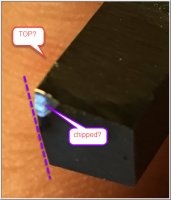

- Cutting tools: when it comes to finish many hobbyists actually prefer HSS over carbides, even on steel. Why? because you can alter tip geometry like nose radius & rake etc just with a grinder & fine hand stone. If you have the wrong carbide selected or cannot operate it at recommended material removal, finish could be worse than HSS. That said, I actually find little difference when both are properly selected. If you are using carbide, check for micro-chip on nose. This has burned me before but your softer alloy finish would be similarly affected. Check you have the correct carbide insert. Ive actually seen incorrect rake inserts sold with tooling even though they may have the correct style shape (triangular or whatever)

- Speeds & feeds: there are textbook numbers but there is some latitude on small lathes when you don't have as much power or you experience vibration or harmonic at certain rpms. A fine feed should yield a decent finish, just takes more time.

- Geometry: ensure tip is on work center

Can you take some pics of your setup & cutting results?