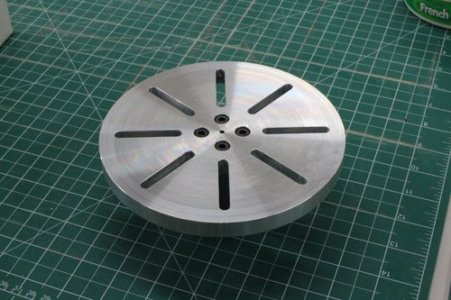

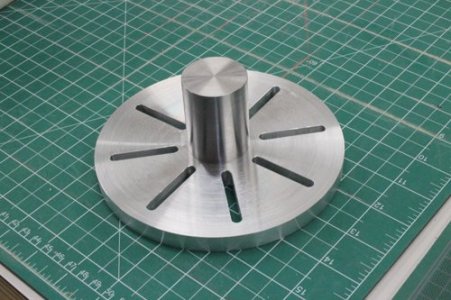

I've had a few setup issues where my standard 11" CI faceplate does not cooperate with the part I want to turn. The face plate casting integrates the D1-4 hub on the back side & that dictates the minimum diameter span of bolt slots, about 5" in my case. So if the part is smaller than this & needs to be retained with through bolts, that's kind of the end of the trail for 'simple'. I've come up with other 1-time holding fixtures in the past but they were kind of sketchy. So I decided to make this smaller one, 6" diameter. Basically a slab of aluminum faced on both sides, bolted to a steel arbor with 4x M5 SHCS. Then 8x 6mm wide slots milled on the RT. I integrated an M3 center dowel pin in both the plate & arbor which mates the 2 parts & is useful for pre-aligning parts if it works out that way. Now the minimum bolt distance is ~ 2". Better for finicky stuff. I hold the ~1.5" arbor in my 6" lathe chuck jaws.

Retaining the plate on 4x SHCS is not really optimal. I'm kind of counting on the bolt clamping pressure alone. But it happens to match bolt pattern for a tooling plate I have so I thought I could swap them on the same arbor. In reality I think taking the plate on & off again from the arbor is not a great idea, it may likely lose accuracy because of the small footprint. Another option to use dowel pins & just one screw to retain it (or maybe a few on a different pattern). That axial force isn't very big comparatively. My material selection was kind of dictating the design on the fly. better if it were steel or CI. I also should have countersunk the cap screws a bit deeper to give me more lifetime skim cuts to true it up if required. But it seems to be holding up & I put it to good use.

Retaining the plate on 4x SHCS is not really optimal. I'm kind of counting on the bolt clamping pressure alone. But it happens to match bolt pattern for a tooling plate I have so I thought I could swap them on the same arbor. In reality I think taking the plate on & off again from the arbor is not a great idea, it may likely lose accuracy because of the small footprint. Another option to use dowel pins & just one screw to retain it (or maybe a few on a different pattern). That axial force isn't very big comparatively. My material selection was kind of dictating the design on the fly. better if it were steel or CI. I also should have countersunk the cap screws a bit deeper to give me more lifetime skim cuts to true it up if required. But it seems to be holding up & I put it to good use.