DPittman

Ultra Member

It's probably been done as many different ways as it has been done in total, but here is what I did for my mill quill readout.

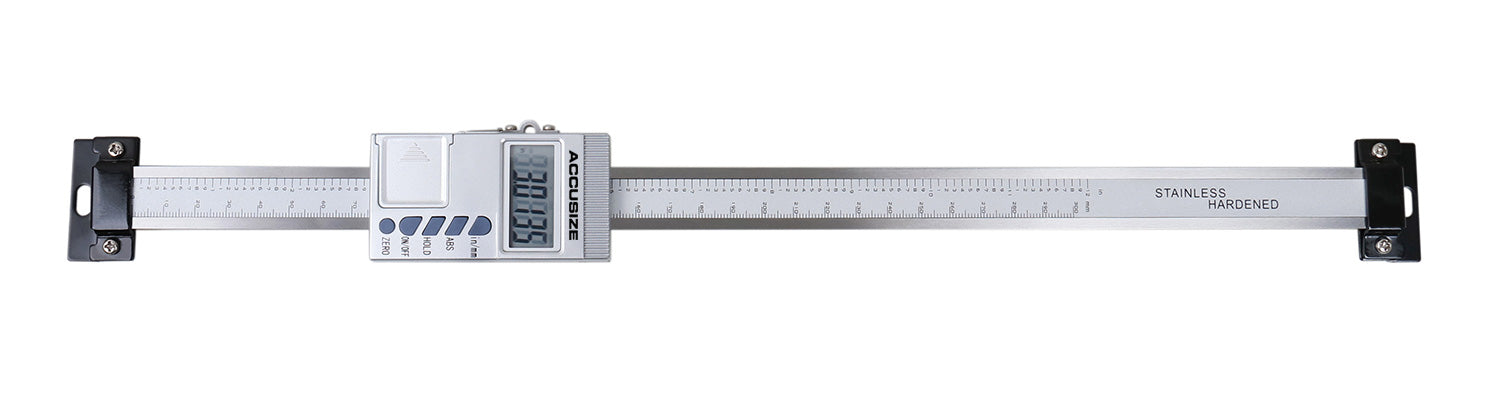

I've thought the available commercial mill quill dro's are overpriced for what they are so I bought a digital caliber on sale at Crappy Tire and hacked it down to fit. The only modification I did to the mill itself was two small 3mm threaded holes for the mounting angle into the existing sliding block that rides up and down on the quill stop. The other end was just a block that threaded onto the stop rod.

Yes the readout is vertical but I can live with that. I always hated the backlash that seemed to vary in the handwheel dial. This was Uber cheap mod but a bit finicky to get the scale straight and true.

I've thought the available commercial mill quill dro's are overpriced for what they are so I bought a digital caliber on sale at Crappy Tire and hacked it down to fit. The only modification I did to the mill itself was two small 3mm threaded holes for the mounting angle into the existing sliding block that rides up and down on the quill stop. The other end was just a block that threaded onto the stop rod.

Yes the readout is vertical but I can live with that. I always hated the backlash that seemed to vary in the handwheel dial. This was Uber cheap mod but a bit finicky to get the scale straight and true.