You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mill mods: auto gibb locks

- Thread starter GKShop

- Start date

I'll be the first to ask why?Hi All,

Has anyone added actuated gib locks to a g0704/cx601 type mill? I am thinking of using quarter turn rotary actuators or stepper motors. Has anyone come across a build log where someone has already done something like that? Or maybe a premade kit?

To lock the gibs when I push a buttonI'll be the first to ask why?

Yeah I got that. But is it so inconvenient to do it manually? Do you do it really often? Is the machine CNC controlled so do you want to lock all at the same time or only the stationary axis?To lock the gibs when I push a button

Inquiring minds need to know.

Haha, ok then, I will explain more than the obvious. It is a little inconvenient to reach the y gibbs, but it’s not that, really. I often forget to engage or disengage whichever ones I need to, so having a panel with a button to push and a status light would be helpful. Maybe I will use one of those fighter jet style covered switches for extra cool factor and to appease my inner child.Yeah I got that. But is it so inconvenient to do it manually? Do you do it really often? Is the machine CNC controlled so do you want to lock all at the same time or only the stationary axis?

Inquiring minds need to know.

Also, I love a project

I think an air cylinder coupled with links would be the way I'd go. Then modify the hand wheel so that you flip the handle inwards to latch so it doesn't stick out. The process of latching it in the unusable position presses a pin which pushes on a disk (or closes a contact) which locks that axis.

As soon as you want to use the Y axis you pull the handle back into the crank position which simultaneously releases the air cylinder on the lock.

How's that for cool but complicated.

As soon as you want to use the Y axis you pull the handle back into the crank position which simultaneously releases the air cylinder on the lock.

How's that for cool but complicated.

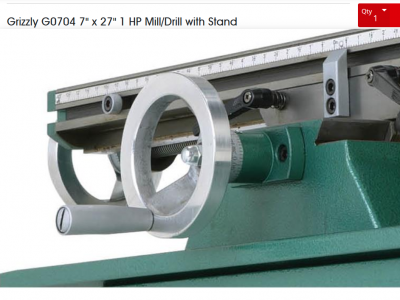

I'm guessing your locks are like this?

And the Y Axis handle is like this:

There are really two projects. Ignore the fancy handle part to start with since that's my rabbit hole journey into complexity.

The clamps on the ways are similar to mine I think. You can adjust them on the splines so they are both at the 4 o'clock position when unlocked and at say the 8 o'clock position when locked.

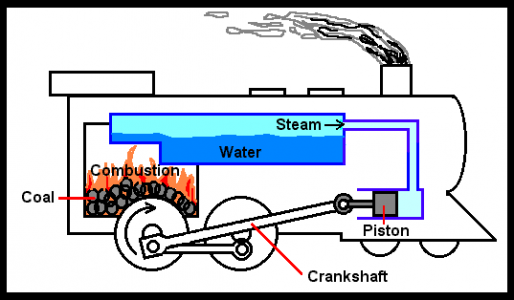

Now an arm between the two connected to the air cylinder. (or DC motor linear actuator). Think of the arm and the movement of the two levers as the connection on a steam locomotive.

Essentially the two locking arms are like the pins on the wheels. The piston is the linear actuator. Or you could replace the leavers with toothed wheels and a toothed belt between the two and then a motor to turn them.

Giant and deep rabbit hole with many passages.

And the Y Axis handle is like this:

There are really two projects. Ignore the fancy handle part to start with since that's my rabbit hole journey into complexity.

The clamps on the ways are similar to mine I think. You can adjust them on the splines so they are both at the 4 o'clock position when unlocked and at say the 8 o'clock position when locked.

Now an arm between the two connected to the air cylinder. (or DC motor linear actuator). Think of the arm and the movement of the two levers as the connection on a steam locomotive.

Essentially the two locking arms are like the pins on the wheels. The piston is the linear actuator. Or you could replace the leavers with toothed wheels and a toothed belt between the two and then a motor to turn them.

Giant and deep rabbit hole with many passages.

Hi All,

Has anyone added actuated gib locks to a g0704/cx601 type mill? I am thinking of using quarter turn rotary actuators or stepper motors. Has anyone come across a build log where someone has already done something like that? Or maybe a premade kit?

You prolly don't need yet another fellow recommending against this project. But that would be me. There are lots of way more useful projects than this one that is a giant rabbit hole. It's very complicated and fraught with opportunities to go wrong.

Personally, I'd work on ways to instill better habits and look for a better project to do. Since you are willing to do some electrical / electronics, why not a simple Arduino reminder that you have to acknowledge regularly. If that doesn't burn in the habit, nothing will. And, you get to play with an Arduino!

I think we had similar things in mind, though I didn’t picture an steam engines. I have a surplus of small timing pullies and nema 17 motors/drivers, so I was thinking of going that angle. I’m dreaming all of this up while on vacation, without being able to look at the machine, so the mind wanders. It’s been an interesting rabbit hole though.

Now I just need a spline cutter for my rotary broach that matches my gib screws…maybe need is a strong word. The pulleys are aluminum so I could also drill them undersized and press them on…but I COULD buy a broach

Now I just need a spline cutter for my rotary broach that matches my gib screws…maybe need is a strong word. The pulleys are aluminum so I could also drill them undersized and press them on…but I COULD buy a broach

Here's what you do. First set up your lathe with a timing belt and pulley or some method of indexing the chuck so you can match the splines.

Then use a HSS tool ground to the correct shape and just use the carriage as a shaper on the pulley hole. Cut the spline groove. Index to next and repeat.

It's a fun rabbit hole but I'd think spending time to add CNC to the mill would be a better rabbit hole.

Then use a HSS tool ground to the correct shape and just use the carriage as a shaper on the pulley hole. Cut the spline groove. Index to next and repeat.

It's a fun rabbit hole but I'd think spending time to add CNC to the mill would be a better rabbit hole.

Yeah something with programable voice module just think of the possible messages like.You prolly don't need yet another fellow recommending against this project. But that would be me. There are lots of way more useful projects than this one that is a giant rabbit hole. It's very complicated and fraught with opportunities to go wrong.

Personally, I'd work on ways to instill better habits and look for a better project to do. Since you are willing to do some electrical / electronics, why not a simple Arduino reminder that you have to acknowledge regularly. If that doesn't burn in the habit, nothing will. And, you get to play with an Arduino!

Don’t forget the lock!

Aw come on!

Jesus I taught my dog!

And my favourite!

Way to go Buckwheat!

I should follow the KISS rule more frequently - but I confess i often build something that takes hours and only occasionally saves a few seconds. So i get why you’re thinking about auto gibb locks. Makes way more sense than many of my projects.

My Z axis gibb locks are on the right side of the mill (RF45 clone) but the raise/lower hand wheel is on the left side. What st##pd engineer design that! (see note below).

My Y axis gibb locking handle not only conflicted with the table (if the Y gibb lock handle is vertical up then it conflicts with the table during X travel) but it is also hard to reach or even see. In photos below - this time I had a simple/quick solution - I attached a socket extension. So maybe @GKShop consider a project to improve gibb lock access and visibility.

(Note: I am an engineer and I don’t mind pocking fun at some fellow engineers that don’t have a practical bone in their body)

My Z axis gibb locks are on the right side of the mill (RF45 clone) but the raise/lower hand wheel is on the left side. What st##pd engineer design that! (see note below).

My Y axis gibb locking handle not only conflicted with the table (if the Y gibb lock handle is vertical up then it conflicts with the table during X travel) but it is also hard to reach or even see. In photos below - this time I had a simple/quick solution - I attached a socket extension. So maybe @GKShop consider a project to improve gibb lock access and visibility.

(Note: I am an engineer and I don’t mind pocking fun at some fellow engineers that don’t have a practical bone in their body)

Attachments

Haha, yeah it sounds like we may have a thing or two in common. Is this where I confess I am an engineer too? Is this a safe space?I should follow the KISS rule more frequently - but I confess i often build something that takes hours and only occasionally saves a few seconds. So i get why you’re thinking about auto gibb locks. Makes way more sense than many of my projects.

My Z axis gibb locks are on the right side of the mill (RF45 clone) but the raise/lower hand wheel is on the left side. What st##pd engineer design that! (see note below).

My Y axis gibb locking handle not only conflicted with the table (if the Y gibb lock handle is vertical up then it conflicts with the table during X travel) but it is also hard to reach or even see. In photos below - this time I had a simple/quick solution - I attached a socket extension. So maybe @GKShop consider a project to improve gibb lock access and visibility.

(Note: I am an engineer and I don’t mind pocking fun at some fellow engineers that don’t have a practical bone in their body)

I often do things like this just because I can and it’s a challenge. I even occasionally learn something, but if I’m careful, I can avoid that.

I’ve enjoyed the conversation, thanks to all for your input, so far. If you would like to make any more suggestions, please feel free. There may be some other fool who wants to try this one day.

Haha, yeah it sounds like we may have a thing or two in common. Is this where I confess I am an engineer too? Is this a safe space?

Me too.

Every discipline gets bashed on here sooner or later. Mostly in fun.

Lotta programmers, welders, farmers, engineers, and even a few machinists .... We should do a survey!

If such a thing as a safe space exists I've never been there.

Haha, yeah it sounds like we may have a thing or two in common. Is this where I confess I am an engineer too? Is this a safe space?

I often do things like this just because I can and it’s a challenge. I even occasionally learn something, but if I’m careful, I can avoid that.

I’ve enjoyed the conversation, thanks to all for your input, so far. If you would like to make any more suggestions, please feel free. There may be some other fool who wants to try this one day.

Safe? From being made to feel dumb? The only thing on this site that is verboten is politics, and maybe being a Leafs fan.

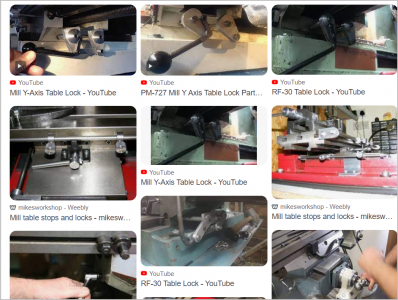

I've seen a few mechanical variations to the '1-handle 2-screw' theme on mini mills. Some Google examples below. I never found it enough of an issue on my RF-45 to make anything special. Anything knob like was too close to table underside due to the diameter if it had any mechanical advantage. The stock handles were the typical sprung type that could be adjusted by pulling out & reset to a different angle on the spline. I just found a position where they tightened about 6:00 (down). To loosen was just 1 full turn, but again residing down. And both handles were adjusted the same. I have found that some handles have less splines for whatever reason. There is no a lot of force on these. In fact if you gronk them you will see a series of bite marks down the gib strip. On my lathe I modified the screw to have a little brass foot angled at same 60-deg gib stril & a bearing ball. Thatway its more like direct oblique force vs turning o the gib strip.

Well the leafs make sense since it's all about drugs right? The leafs from the marijuana plant? And we don't talk about drugs.Safe? From being made to feel dumb? The only thing on this site that is verboten is politics, and maybe being a Leafs fan.

Those pictures have given me some ideas on how to possibly fix my X slide on my mill lock. There are two hex head bolts for my gib locks but since I put on DRO scales in the front there only 1 of the hex head bolts is accessible. Thanks for the ideas.I've seen a few mechanical variations to the '1-handle 2-screw' theme on mini mills. Some Google examples below. I never found it enough of an issue on my RF-45 to make anything special. Anything knob like was too close to table underside due to the diameter if it had any mechanical advantage. The stock handles were the typical sprung type that could be adjusted by pulling out & reset to a different angle on the spline. I just found a position where they tightened about 6:00 (down). To loosen was just 1 full turn, but again residing down. And both handles were adjusted the same. I have found that some handles have less splines for whatever reason. There is no a lot of force on these. In fact if you gronk them you will see a series of bite marks down the gib strip. On my lathe I modified the screw to have a little brass foot angled at same 60-deg gib stril & a bearing ball. Thatway its more like direct oblique force vs turning o the gib strip.

View attachment 37385

Dan Dubeau

Ultra Member

I don't think auto gib locks would be a useless pursuit. I actually think it would be a great project that would pay dividends every time you use your mill. If you're an "air shop" and always have your compressor going, then I'd go that route. Should be easy enough to make some screws with a lever mechanism activated by an air cylinder. A simple valve to actuate them, and it would be out front and easy to see if they're locked or not. Even without the air on, you could still operate the locks easily, and make the linkage would tie them together.