-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mill dro

- Thread starter Garyt

- Start date

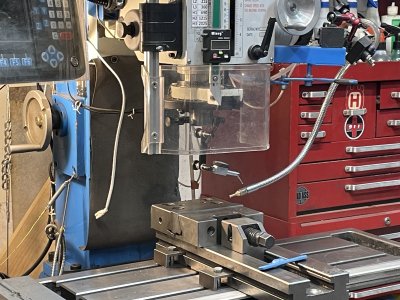

Here’s mine, RF30 round column with Amazon $300 DRO.

Y-axis is nice and solid, a few chunks of aluminum angle, drilled and tapped a couple of holes in the base. Notched angle bar to clear the x-axis lead screw.

X-axis attaches to the limit switch slot in the front of the table, with a couple of holes drilled and tapped for the reader head. PITA, it blocks the travel locks. New Years project is to pull it all apart and drill and tap the table to mount the scale and reader on the back of the table closer to the column. I’ll lose a bit of table travel but will then regain use of the travel locks.

Z-axis is inside the mill head, completely protected. Drilled a couple of holes to mount the read head, and Rube-Goldberged a bracket to connect the scale. Head is fixed, scale moves. Other New Years project is to fabricate a better scale mounting arrangement.

Y-axis is nice and solid, a few chunks of aluminum angle, drilled and tapped a couple of holes in the base. Notched angle bar to clear the x-axis lead screw.

X-axis attaches to the limit switch slot in the front of the table, with a couple of holes drilled and tapped for the reader head. PITA, it blocks the travel locks. New Years project is to pull it all apart and drill and tap the table to mount the scale and reader on the back of the table closer to the column. I’ll lose a bit of table travel but will then regain use of the travel locks.

Z-axis is inside the mill head, completely protected. Drilled a couple of holes to mount the read head, and Rube-Goldberged a bracket to connect the scale. Head is fixed, scale moves. Other New Years project is to fabricate a better scale mounting arrangement.

And here is mine. Lots of details included.

Thread 'Installing a DRO on a Hartford Bridgeport Clone.' https://canadianhobbymetalworkers.com/threads/installing-a-dro-on-a-hartford-bridgeport-clone.4852/

Thread 'Installing a DRO on a Hartford Bridgeport Clone.' https://canadianhobbymetalworkers.com/threads/installing-a-dro-on-a-hartford-bridgeport-clone.4852/

trlvn

Ultra Member

I installed a new DRO on my round column a couple of months ago. Start at:

Craig

To close out this thread, I have just finished replacing the DRO on my RF-30 style mill. To recap, the X axis on my old DRO regularly made a clicking sound and that sometimes seemed to cause the display to jump 15-20 thous. After taking the read head off, I could no longer get it to work at all. Still have no idea what went so badly wrong. I decided to buy a new, modern DRO.

I looked at Aikron, Ditron and Sino. Reviewed past threads and info on the Touch DRO site and decided that I wanted glass scales. Decided that there was enough room so that I didn't need Slim or Xtra-slim...

I looked at Aikron, Ditron and Sino. Reviewed past threads and info on the Touch DRO site and decided that I wanted glass scales. Decided that there was enough room so that I didn't need Slim or Xtra-slim...

Craig

I would recommend making a small block for a drill and tapping guide so you get the holes and taps straight. That is what I did with a small (maybe 1.5" x 3" x0.5" thick) piece of aluminum. You can hold it in place by hand or a clamp when you need both hands. I used it start the drill and the tap. One hole for the drill size and one hole tapped so I could tap through from the block for the first few threads then remove the block. Just mark the holes so you don't drill the threaded one.

Does my photo show up?

When I look it is there for a second then disappears.

Gary

Has something to do with the way you posted the image. What I don't know. Happening more and more these days.

Morning Gary

I’m a little late seeing this thread - but your last picture indicates you have not done the install yet. - so here’s how I installed the X scale (Y & Z have lots of room and thus a bit easier)

I have an X power feed limit switch at the front, so I put the X dro scale/reader at the back.

I don’t notice, until later, but the X scale was covering access to this gib oiler:

I should have installed it higher up. Also, the installation at the rear takes away about 1” of Y travel. Since I needed to relocate it (to get access to the oiler), I decided to move it to the front (and get back that Y travel)

Here a pic of the front of my RF45 clone

The blue bracket holds both the X dro reader and the X power feed limit switch as seen here:

Here the pencil is on the X magnetic scale

This shows access to the oiler:

While crouched down there taking those pictures - here’s a couple shots of the linkage for the Y gib lock

I’m a little late seeing this thread - but your last picture indicates you have not done the install yet. - so here’s how I installed the X scale (Y & Z have lots of room and thus a bit easier)

I have an X power feed limit switch at the front, so I put the X dro scale/reader at the back.

I don’t notice, until later, but the X scale was covering access to this gib oiler:

I should have installed it higher up. Also, the installation at the rear takes away about 1” of Y travel. Since I needed to relocate it (to get access to the oiler), I decided to move it to the front (and get back that Y travel)

Here a pic of the front of my RF45 clone

The blue bracket holds both the X dro reader and the X power feed limit switch as seen here:

Here the pencil is on the X magnetic scale

This shows access to the oiler:

While crouched down there taking those pictures - here’s a couple shots of the linkage for the Y gib lock

Garyt

Well-Known Member

I think I'm done just some clean up (isn't there always).Morning Gary

I’m a little late seeing this thread - but your last picture indicates you have not done the install yet. - so here’s how I installed the X scale (Y & Z have lots of room and thus a bit easier)

I have an X power feed limit switch at the front, so I put the X dro scale/reader at the back.

I don’t notice, until later, but the X scale was covering access to this gib oiler:

View attachment 58134

I should have installed it higher up. Also, the installation at the rear takes away about 1” of Y travel. Since I needed to relocate it (to get access to the oiler), I decided to move it to the front (and get back that Y travel)

Here a pic of the front of my RF45 clone

View attachment 58135

The blue bracket holds both the X dro reader and the X power feed limit switch as seen here:

View attachment 58136View attachment 58137

Here the pencil is on the X magnetic scale

View attachment 58138

This shows access to the oiler:

View attachment 58139

While crouched down there taking those pictures - here’s a couple shots of the linkage for the Y gib lock

View attachment 58140View attachment 58141

I covered the oiler on the back so not sure what I'm going to do about that. The scale on the back only cost me 2 or 3 mm so not too bad.

I have a few pictures and can post if anyone is interested.

Garyt

Well-Known Member

I like the y gib lock. Did you make that? I use it to get my hand dirty.Morning Gary

I’m a little late seeing this thread - but your last picture indicates you have not done the install yet. - so here’s how I installed the X scale (Y & Z have lots of room and thus a bit easier)

I have an X power feed limit switch at the front, so I put the X dro scale/reader at the back.

I don’t notice, until later, but the X scale was covering access to this gib oiler:

View attachment 58134

I should have installed it higher up. Also, the installation at the rear takes away about 1” of Y travel. Since I needed to relocate it (to get access to the oiler), I decided to move it to the front (and get back that Y travel)

Here a pic of the front of my RF45 clone

View attachment 58135

The blue bracket holds both the X dro reader and the X power feed limit switch as seen here:

View attachment 58136View attachment 58137

Here the pencil is on the X magnetic scale

View attachment 58138

This shows access to the oiler:

View attachment 58139

While crouched down there taking those pictures - here’s a couple shots of the linkage for the Y gib lock

View attachment 58140View attachment 58141

Megar arc 5040dd

Super User

I love that Y lock I am totally going to borrow that!

On the Forum we love pictures - post away (also pics often get an interesting discussion started because of something in the background)w pictures and can post if anyone is interested

You will have to deal with the covered-up oiler!! The magnetic strip (tape) is the important part of the X magnetic scale. The aluminum housing is much wider than the tape. Take off one of the ends, slip out the SS cover, trim the aluminum housing (for an inch or so), and give yourself an access spot to the oiler. If the tape is not centered in the aluminum housing, you can flip it over and then trim some more. Flipping it will only just change whether left to right is +ve or -ve.

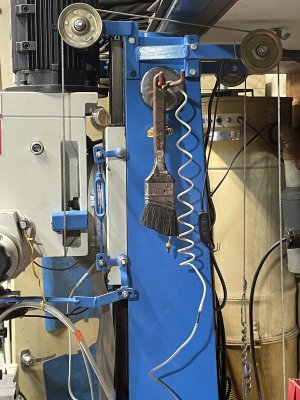

You might also like my Z gib locks.that Y lock I am totally going to borrow that!

After installing the Z counter balance, moving the head up or down was much easier and I could then do it from the front of the machine (using a smaller and faster wheel instead of a large crank). I added a Z gib linkage so that I could reach both the Z wheel (on the left) and activate the gib locks at the same time.

View from front, note Z wheel on left and lever on right:

View of counterbalance cables and Z gib locks linkage:

and a couple of closer views of the linkage: