-

Spring 2024 meetup in Calgary - date Saturday, April 20/2024. discussion Please RSVP Here to confirm and get your invitation and the location details. RSVP NOW so organizers can plan to get sufficient food etc. It's Tomorrow Saturday! you can still RSVP until I stop checking my phone tomorrow More info and agenda

-

We are having email/registration problems again. Diagnosis is underway. New users sorry if you are having trouble getting registered. We are exploring different options to get registered. Contact the forum via another member or on facebook if you're stuck. Update -> we think it is fixed. Let us know if not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M20x2.5 Tap

- Thread starter SomeGuy

- Start date

Any recommendations on taps this size? Drill America on Amazon has a 3 piece set with the different tapers for just under $100....but anything else out there at a reasonable price?

It's the standard speaker pole thread size, just need to do a couple holes to make some adapters

M20 is just over 3/4, hence the high cost. If it's a through hole, you don't need the set and could just buy the one tap.

In the beginning I bought tap sets. Now I always buy a high quality 3 or 2 tap set at the local jobber. It costs more but I only buy what I need and they are great taps.

Amazon has Sowa taps that are pretty darn good.

Search on "Sowa M20 tap" and scroll down. They are generally around 100 each but they sell all 3. Lotta coin. I guess it depends ho much you think you might use it.

A lathe sounds like a pretty good option.....

SomeGuy

Hobbyist

You can't cut them in the lathe?

I've cut external M20 on the lathe...internal feels like it would be tight?

Ironman

Ultra Member

I just ordered this one for my pedestal project. I would not spend a lot of money on something that is infrequently use or is for soft or thin metals.

You shouldn't have any trouble with internal threading of that size. I have no problem doing 9/16 internal using the set of threaders linked and you're doing a bigger thread than that.

I've cut external M20 on the lathe...internal feels like it would be tight?

Ya, it gets tighter the smaller you go. Once you get down in diameter your tooling choices become limited to HSS or solid carbide. You can grind HSS to do the job or buy pre-ground carbide. But either way you won't be cutting very deeply. It will also feel a bit like scratching out a thread instead of cutting one. I've never single point cut a thread smaller than 1/2. But I'm sure even smaller is possible. However, as the size goes down, so does the cost of taps, till taps become the obvious no-brainer solution.

SomeGuy

Hobbyist

Ya, it gets tighter the smaller you go. Once you get down in diameter your tooling choices become limited to HSS or solid carbide. You can grind HSS to do the job or buy pre-ground carbide. But either way you won't be cutting very deeply. It will also feel a bit like scratching out a thread instead of cutting one. I've never single point cut a thread smaller than 1/2. But I'm sure even smaller is possible. However, as the size goes down, so does the cost of taps, till taps become the obvious no-brainer solution.

I have taps and dies up to M18...just something I'm more comfortable with than internal single point threading...which I've never actually done lol, only external.

Basically need to make some of these:

GFW20204179RP – Sub Pole Adapter – Gator Shop

I actually have a set of these exact ones that came with my Gator poles, but I don't like the loose fit in some new subs I got and want to make a set with the OD slightly larger and a very very slight taper. Short term I can wrap with electrical tape to snug it up, but that's not ideal.

Any recommendations on taps this size?

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

Or maybe this fellow happens to have one @ronb11

Tools and misc cutters for sale

Hello Everyone, I'm new here and recently came across this site. I am a retired machinist who has been in the trade since 1980. Over the years I have accumulated (like alot of you I'm sure) an abundance of tools and cutters that I no longer have a need for. I recently retired and have downsized...

Could always make one out of bolt works ok with aluminum or just buy 1 starting tap and after threading to max depth on all parts cut tap it to make it bottoming tap

Or if your not in rush less then 20$ AliExpress

Last edited:

Yes at this size, as mentioned, the big name manufacturer stuff will be expensive.

I've bought some good taps from Ali but shipping can be anywhere from 2-5 weeks depending on vendor & all the usual variables. I've had notice landing within 1 week & it sits in Customs for 3. But the vendors are getting smarter & warehousing many items in country. The transaction goes to China, but the part comes from Ontario LOL

Amazon mystery metal if you need to get going quick

Accusize likely very similar mystery metal. Purchasing through Amazon is usually lower all in cost vs direct. Either way returns seem to be straightforward if its a dud

Better quality (if necessary) available on any number of tooling outlets. The kicker is cost, min order $, min shipping $, pickup vs delivery etc.

KBC typically handles European or USA lines, but wow the prices.

www.kbctools.ca

www.kbctools.ca

www.sowatool.com

www.sowatool.com

I've bought some good taps from Ali but shipping can be anywhere from 2-5 weeks depending on vendor & all the usual variables. I've had notice landing within 1 week & it sits in Customs for 3. But the vendors are getting smarter & warehousing many items in country. The transaction goes to China, but the part comes from Ontario LOL

Amazon mystery metal if you need to get going quick

Accusize likely very similar mystery metal. Purchasing through Amazon is usually lower all in cost vs direct. Either way returns seem to be straightforward if its a dud

Better quality (if necessary) available on any number of tooling outlets. The kicker is cost, min order $, min shipping $, pickup vs delivery etc.

KBC typically handles European or USA lines, but wow the prices.

Results Page 1 :: KBC Tools & Machinery

Spiral Point Taps - Taps

Spiral Point Taps, • Brand: Cleveland<br>• Model Number: C57009<br>• Overall Length (Decimal Inch): 1.625"<br>• Thread Standard: UNF<br>• Thread Length (Decimal Inch): 0.3125"<br>• Series: 1011<br>• Shank Diameter (Decimal Inch): 0.141"<br><br>If not stocked at Sowa, typically ships in 1-3 days...

For that, I'd just buy a single tapered tap and go for it. Choose the quality you can afford. The amazon Sowa taps are good ones. If you have lots of bar stock, you can also buy a cheap one and not worry about breaking it. Just pitch it if that happens and cut a new one.

If you mean you want a very very slight thread taper, this will be difficult unless you have a taper attachment. No big deal if you mean the OD.

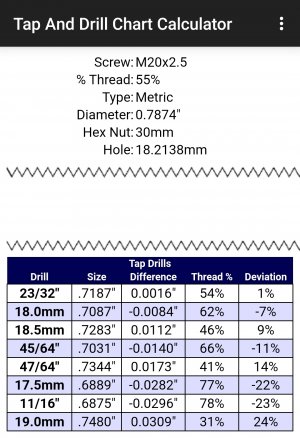

I'd recommend a higher percent fit to kill the sloppiness. The only downside is higher risk of breaking the tap. Choose the percent fit from the following chart and test fit a few holes till you find what works best.

This a screen shot from the Tap and Drill Chart Calculator for M20x2.5 thread on my Android phone.

The alternative is to learn to inside single point. No time like the present to learn new skills.

and a very very slight taper

If you mean you want a very very slight thread taper, this will be difficult unless you have a taper attachment. No big deal if you mean the OD.

I'd recommend a higher percent fit to kill the sloppiness. The only downside is higher risk of breaking the tap. Choose the percent fit from the following chart and test fit a few holes till you find what works best.

This a screen shot from the Tap and Drill Chart Calculator for M20x2.5 thread on my Android phone.

The alternative is to learn to inside single point. No time like the present to learn new skills.

SomeGuy

Hobbyist

For that, I'd just buy a single tapered tap and go for it. Choose the quality you can afford. The amazon Sowa taps are good ones. If you have lots of bar stock, you can also buy a cheap one and not worry about breaking it. Just pitch it if that happens and cut a new one.

If you mean you want a very very slight thread taper, this will be difficult unless you have a taper attachment. No big deal if you mean the OD.

I'd recommend a higher percent fit to kill the sloppiness. The only downside is higher risk of breaking the tap. Choose the percent fit from the following chart and test fit a few holes till you find what works best.

This a screen shot from the Tap and Drill Chart Calculator for M20x2.5 thread on my Android phone.

The alternative is to learn to inside single point. No time like the present to learn new skills.

Not tapered threads, taper of the body of that insert so it fits more snugly in the pole socket (the pole socket also has a slight taper).

140mower

Don

....not difficult at all, just use my lathe. I get a custom taper on everything I make with it.If you mean you want a very very slight thread taper, this will be difficult unless you have a taper attachment

X2 on single pointing them on the lathe. I find that each time I challenge myself to try a new technique my confidence level rises twofold.

Tom Kitta

Ultra Member

God, people its metric - this is easy and CHEAP to get.

10sec search -

13 CAD.

Come on METRIC == cheap and easy to get. And IMPERIAL == difficult and expensive. Metric is used by like 95% of the world.

10sec search -

13 CAD.

Come on METRIC == cheap and easy to get. And IMPERIAL == difficult and expensive. Metric is used by like 95% of the world.

140mower

Don

.....in two weeks time, or grind a cutter, and single point it this afternoon....God, people its metric - this is easy and CHEAP to get.

10sec search -

13 CAD.

Come on METRIC == cheap and easy to get. And IMPERIAL == difficult and expensive. Metric is used by like 95% of the world.

SomeGuy

Hobbyist

God, people its metric - this is easy and CHEAP to get.

10sec search -

13 CAD.

Come on METRIC == cheap and easy to get. And IMPERIAL == difficult and expensive. Metric is used by like 95% of the world.

I was trying to avoid Chinesium...that was the point in asking here, like if there were nice domestic (or at least not china) made taps at a reasonable price somewhere.

Please don’t hit me when I suggest this. M20 x 2.5 converted to imperial is 0.787” x 0.0984” pitch. Really effing close to imperial 3/4”-10tpi. Before I spent $$$ on a tap, I’d be trying a 3/4” nut or bolt and seeing how sloppy or tight they fit to your existing hardware.

Tom Kitta

Ultra Member

I was trying to avoid Chinesium...that was the point in asking here, like if there were nice domestic (or at least not china) made taps at a reasonable price somewhere.

Well, chances of that are ... realistically nil. Besides don't discount China or imports from Asia (other than maybe India) - As my favorite review guy just did drill bit test and the cheapest (!) and most expensive sets performed equally, one at $11 the other at $200 (I assume US). He is not a machinist so sadly he did not test the size of hole drilled for accuracy or how concentric they were. Viking drill bit set vs. Dewalt. Author recommended ... China (or Thailand) - US did not even make any secondary recommendations.

That does not mean you occasionally don't get crap from China even today - the main issue with Chinese taps is that they are too hard - i.e. especially small ones are prone to cracking and breaking off easily. With M20 x 2.5 this should not be an issue. Thus I would not be shocked for Chinese tap to out perform US made tap in mild steel or even stainless. Just don't hit it from the side.

Also avoid coated stuff - it seems to not be sharp enough and with over hardened metal cracking is assured even on first use (!!!) in sizes such as M6.

I would also be not surprised to find out that Chinese in cheap stuff use something emulating tool steel and to have proper long lasting edge they overharden cheaper alloy. Just a thought through.

@SomeGuy - a flat rate box that will EASILY fit your tap is just $17 at Canada Post. Max weight is 5kg.

www.canadapost-postescanada.ca

www.canadapost-postescanada.ca

Scroll down for the sizes and prices.

Send a flat rate box | Personal

Send a parcel anywhere in Canada using our flat rate boxes and avoid searching for packaging or any surprise shipping costs.

Scroll down for the sizes and prices.