-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lost foam aluminium casting issues

- Thread starter Gennady

- Start date

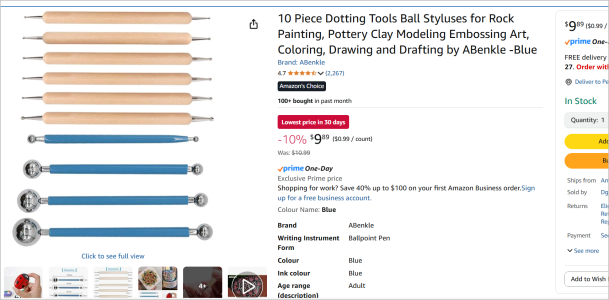

Cool, I’m gonna look at a set.FYI - I bought a set of graduated diameter ball ended tools off Amazon for making fillets & similar. I was using a piece of brass tube CA-glued to a bearing ball, but $10 for a 10-piece set why bother.

View attachment 66435

I have not tried it yet. But it makes a lot of sense. Styrofoam cup makes a perfect pouring cup when its down in the sand. I've used a coffee can with both ends cut out for years to act as the pouring bowl. With the foam gate just above the height of the sand and try to pour as close to center as I can. With the cup idea its already all made and ready to go. For me this is one of those why did I not do this before kind of things.Folks, what is that about styrofoam cups? I've seen it several times being user for pouring and thought - it is out of simplicity or convenience. is there any pointers - why, what? how ?

Thanks !

Tobho Mott

Well-Known Member

Those wheels came out great, Gippeto!

I cheated. Made mine out of cheap set of 4 double ended cake decorating ball tools. Close as I can measure they range from 5/32" to 3/4" in diameter. I just had to cut the shafts in half and make some nicer handles for them. Well I didn't HAVE to, but the blue rubbery sleeves that came on the shafts started getting burnt and melty looking quickly. Works great with wax fillets (or bondo etc, though not with lost foam) but I still need to get one of those alcohol lamps eventually too, getting by with an old bag of tea light candles meanwhile.

Edit - didn't see the pic above of blue sleeved rock painting ball tools identical to my cake decorating ball tools until after posting. 🙂

Jeff

🙂I made my own fillet tools by welding various size balls to wire/rod. Even picked up an alcohol lamp from a local antique store. Showed my FIL and he laughed and said I could have just borrowed/had all his old ones, as he's a retired patternmaker, but where's the fun in that.

I cheated. Made mine out of cheap set of 4 double ended cake decorating ball tools. Close as I can measure they range from 5/32" to 3/4" in diameter. I just had to cut the shafts in half and make some nicer handles for them. Well I didn't HAVE to, but the blue rubbery sleeves that came on the shafts started getting burnt and melty looking quickly. Works great with wax fillets (or bondo etc, though not with lost foam) but I still need to get one of those alcohol lamps eventually too, getting by with an old bag of tea light candles meanwhile.

Edit - didn't see the pic above of blue sleeved rock painting ball tools identical to my cake decorating ball tools until after posting. 🙂

Jeff

Last edited:

Mine just arrived. I'm not sure the small ones will be useful but the blue handled ones should be better than the ball bearing I have on a rod. To low a cost to not buy it.FYI - I bought a set of graduated diameter ball ended tools off Amazon for making fillets & similar. I was using a piece of brass tube CA-glued to a bearing ball, but $10 for a 10-piece set why bother.

View attachment 66435

I just got the same set that Peter posted as well for 10 bucks you can’t go wrong. The larger ones have a good weight to them. The small wood hand set seem really small but I think they are gonna work good for working on my cosplay stuff,Mine just arrived. I'm not sure the small ones will be useful but the blue handled ones should be better than the ball bearing I have on a rod. To low a cost to not buy it.

Where are you guys buying crucible materials from ?

Have been using these off Amazon for aluminum. I bake them in the oven @250F for 3-4 hrs then bring to full temp (empty) in the furnace. Close up the furnace with the crucible inside and let cool overnight. Inspect when cool (see if it "rings" when tapped lightly with a wrench) and then use as normal. If by chance it does not ring...contact the seller and do not use it. (All that I've purchased have been good thus far)

They hold up well if you treat them gently. This one had 20 melts on it at the time the pic was taken, still going after 40+. Once empty, I put them back in the furnace to cool slowly, the little bit of aluminum left in them peels right out once they're cool.

Attachments

Tobho Mott

Well-Known Member

FWIW I just got a tip from a friend in Montreal that you can buy the same top quality crucibles from Asbury Wilkinson in Chateauguay as they have at Foundry Supply Source in Milton ON, for as much as 40% cheaper.

Edit -John Papaionnou, the sales guy in Milton, is a great guy to deal with, very helpful.

Jeff

Edit -John Papaionnou, the sales guy in Milton, is a great guy to deal with, very helpful.

Jeff