TorontoBuilder

Sapientia et Doctrina Stabilitas

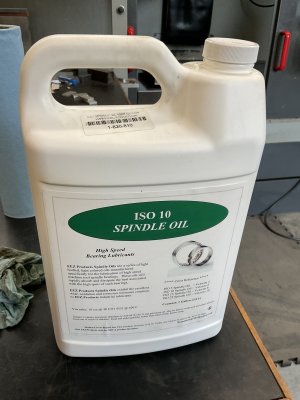

Does anyone know where to buy ISO 2 spindle oil... viscosity between 1.3 and 2?

The surface grinder uses a lubricated head.... and the lack of oil is holding up our testing.

I may use the lightest oil I have just to test then drain and refill with good stuff once I find some.

The surface grinder uses a lubricated head.... and the lack of oil is holding up our testing.

I may use the lightest oil I have just to test then drain and refill with good stuff once I find some.