We bought a new to us TechnoGym treadmill at auction. It is a commercial machine, everything is Made in Italy. The power cord was jammed up against something in the past and broke off what I think is a line noise suppression capacitor.

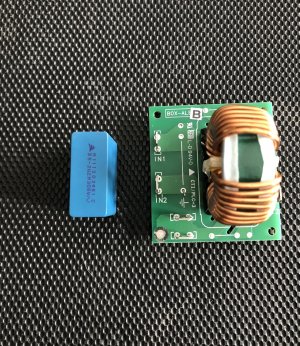

Here are some pictures.

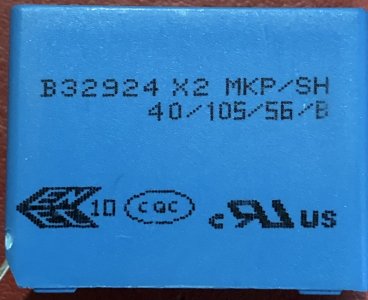

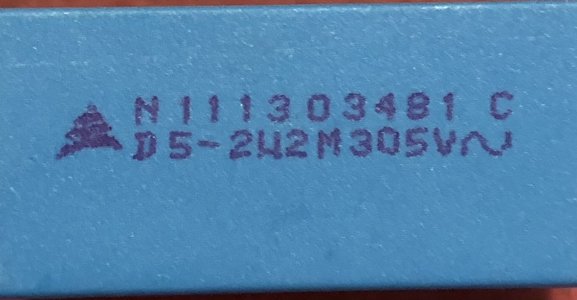

The second picture in the top row shows where it should be located beside the choke on the accessory board. The subsequent ones show the identification marks on the component.

Can someone please confirm that this would be the equivalent part (link to Mouser website, as an example). Thanks!

As an aside:

This treadmill is a beast. It has a 1.8 KW (2.4 hp), 230 VAC, 3 phase motor. Not the more common 90VDC type. It must have some sort of built-in VFD. The belt rollers are 3.5” OD machined aluminum with a steel axle running through them. The bearings are massive. A big Poly-V belt with spring auto tensioner is transmitting the power from the motor.

Here are some pictures of the electronics / motor.

There are two cooling fans in the electronic enclosure - one is visible to the left of the massive heat sink, the other is part of the cover, which I took off for inspection. The big ring on the left side of the motor is a balanced, heavy flywheel.

Here are some pictures.

The second picture in the top row shows where it should be located beside the choke on the accessory board. The subsequent ones show the identification marks on the component.

Can someone please confirm that this would be the equivalent part (link to Mouser website, as an example). Thanks!

As an aside:

This treadmill is a beast. It has a 1.8 KW (2.4 hp), 230 VAC, 3 phase motor. Not the more common 90VDC type. It must have some sort of built-in VFD. The belt rollers are 3.5” OD machined aluminum with a steel axle running through them. The bearings are massive. A big Poly-V belt with spring auto tensioner is transmitting the power from the motor.

Here are some pictures of the electronics / motor.

There are two cooling fans in the electronic enclosure - one is visible to the left of the massive heat sink, the other is part of the cover, which I took off for inspection. The big ring on the left side of the motor is a balanced, heavy flywheel.