Jayham

Well-Known Member

I bought a parts kits Logan 1825. I've been assessing the individual assemblies and their parts, freeing up seized shafts etc. determining missing components.

I have identified several issues,

. So far nothing out of my ability or capability to repair/remake. With one exception.

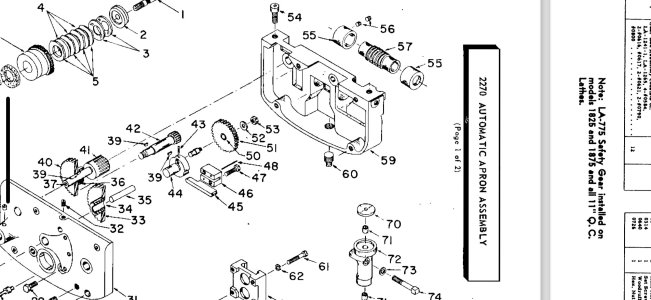

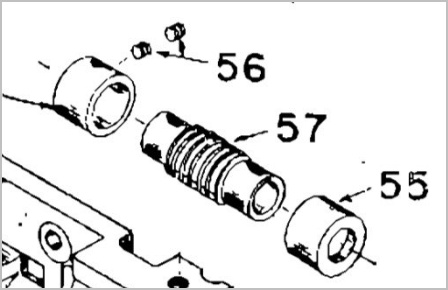

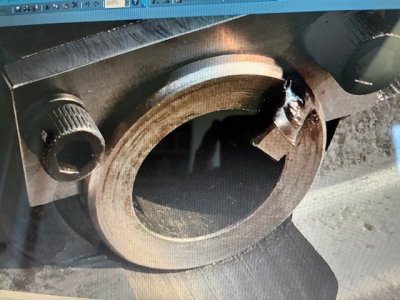

This worm gear which runs off the lead screw keyway. It powers the power and cross feeds. The internal male key is mostly broken away and unlikely to survive much longer. I believe it was made of cast iron. Something that would be unlikely to increase wear in the lead screw.

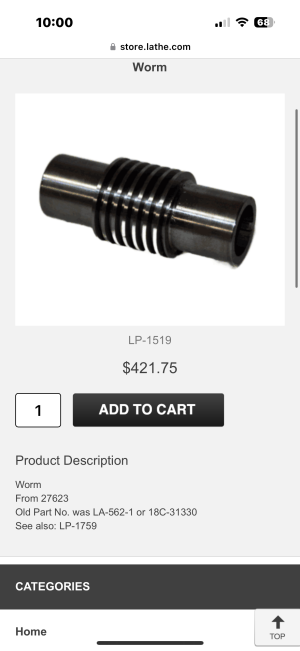

A replacement can be purchased but a nearly $700 after conversion, shipping, taxes and tariffs. Taking on repair makes more sense.

The lead screw keyway is 0.125"

The internal male key is 0.080"( was likely slightly larger)

Ideally I would like to overbore the gear and bush it with a bearing and key. But not sure how to tackle this since the key is internal, male and needs to remain stationary and enough clearance to allow for carriage movement.

The "best" idea I have so far is too bore and bush, then use 4 set screws to become a "key". But the forces required they would need to be steel and I'm concerned about lead screw wear.

I'm all ears for ideas. Anyways equipment available is a lathe, mill and shaper.

Here's a few pictures of what I'm dealing with.

I have identified several issues,

. So far nothing out of my ability or capability to repair/remake. With one exception.

This worm gear which runs off the lead screw keyway. It powers the power and cross feeds. The internal male key is mostly broken away and unlikely to survive much longer. I believe it was made of cast iron. Something that would be unlikely to increase wear in the lead screw.

A replacement can be purchased but a nearly $700 after conversion, shipping, taxes and tariffs. Taking on repair makes more sense.

The lead screw keyway is 0.125"

The internal male key is 0.080"( was likely slightly larger)

Ideally I would like to overbore the gear and bush it with a bearing and key. But not sure how to tackle this since the key is internal, male and needs to remain stationary and enough clearance to allow for carriage movement.

The "best" idea I have so far is too bore and bush, then use 4 set screws to become a "key". But the forces required they would need to be steel and I'm concerned about lead screw wear.

I'm all ears for ideas. Anyways equipment available is a lathe, mill and shaper.

Here's a few pictures of what I'm dealing with.