Recently there have been a few posts on lathe stop projects. If you posted one why don't you move it here.

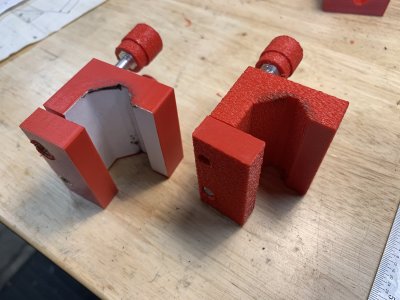

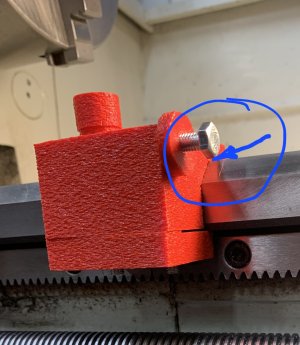

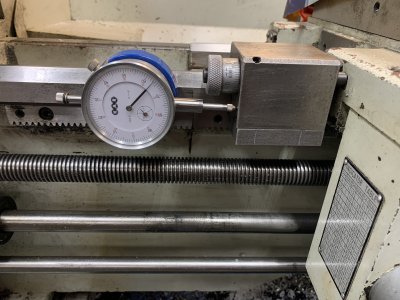

Here are my 3d printed versions. The first one shows 3d printed fuzzy skin as an experiment. I tried smooth, fuzzy, and paper as gripping surfaces. Problem with them so far is even a very light tap from the carriage and the stop moves. The third pic is another revision with a larger nut plate and also a perpendicular hole for mounting an adjustable stop bolt. I'm going to go try that.

Here are my 3d printed versions. The first one shows 3d printed fuzzy skin as an experiment. I tried smooth, fuzzy, and paper as gripping surfaces. Problem with them so far is even a very light tap from the carriage and the stop moves. The third pic is another revision with a larger nut plate and also a perpendicular hole for mounting an adjustable stop bolt. I'm going to go try that.