-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe Spindle End- Play

- Thread starter thestelster

- Start date

Brent H

Ultra Member

When I rebuilt my Utilathe this was a big question so I went to the pros:

This explains a lot. Just like the wheel bearings in your car you can torque (load) the bearing and then relax that load (loosen the nut a bit) to remove all end play yet maintain tolerances, suggested running temps etc.

Hope this helps

This explains a lot. Just like the wheel bearings in your car you can torque (load) the bearing and then relax that load (loosen the nut a bit) to remove all end play yet maintain tolerances, suggested running temps etc.

Hope this helps

Something no-one has mentioned yet (or perhaps I didn't notice it) is the difference between setting the preload during maintenance and preload after a month of use.

Most bearing preload specifications are designed to be used during initial setup or after a repair. They are not meant to be a regular routine maintenance adjustment. Certainly that is the case for automotive bearings. It might be different for machines.

But my understanding is that the allowable temperature increase is there to ensure that the bearings will stay reasonably tight for a very long time, and that any heat build up is actually detrimental to long term life expectancy. It's basically a reasonable tradeoff. I don't know if that applies to spindle preload but it's at least worth thinking about it.

I definitely agree with what @BrentH said. It's usually better to slightly over tighten and then back off than it is to slowly tighten till you reach the desired set point.

My primary experience is automotive not machines. But it's hard for me to see why a shop machine should be significantly different other than perhaps the more severe environmental range associated with driving on the road in Arizona & Mexico vs Thompson Manitoba.

Most bearing preload specifications are designed to be used during initial setup or after a repair. They are not meant to be a regular routine maintenance adjustment. Certainly that is the case for automotive bearings. It might be different for machines.

But my understanding is that the allowable temperature increase is there to ensure that the bearings will stay reasonably tight for a very long time, and that any heat build up is actually detrimental to long term life expectancy. It's basically a reasonable tradeoff. I don't know if that applies to spindle preload but it's at least worth thinking about it.

I definitely agree with what @BrentH said. It's usually better to slightly over tighten and then back off than it is to slowly tighten till you reach the desired set point.

My primary experience is automotive not machines. But it's hard for me to see why a shop machine should be significantly different other than perhaps the more severe environmental range associated with driving on the road in Arizona & Mexico vs Thompson Manitoba.

Ok, I've tightened the adjusting ring by 1/4 turn. This has brought the end play down from 0.0010 to 0.0002". The max temperatures recorded at the bearings were 107°F (41.7°C).

I'm done for tonight. I will check the end play tomorrow morning once everything has cooled down, and adjust if necessary. I've been running the lathe at 425rpm, but I'd like to check temperatures at the max which is 1050rpm.

I'm done for tonight. I will check the end play tomorrow morning once everything has cooled down, and adjust if necessary. I've been running the lathe at 425rpm, but I'd like to check temperatures at the max which is 1050rpm.

2 tenths is well withig expected elastic deformation. If it keeps rising to 41, you might back off a tenth turn or so. End play under load and free play are different animals. You can live with 3 or 4 tenths of end play under load. 3 tenths of free play is not very good at all.

Hey John, can you explain the the differences between those terms and how I would determine those dimensions and how to adjust them, please.2 tenths is well withig expected elastic deformation. If it keeps rising to 41, you might back off a tenth turn or so. End play under load and free play are different animals. You can live with 3 or 4 tenths of end play under load. 3 tenths of free play is not very good at all.

Ok, I started her up, taking temps along the way, spindle speed @425rpm. After 15 minutes temps were 85°F (30°C). So I increased spindle speed to 1050rpm. Temps were rising pretty quickly. @10minutes 120°F (49°C)

@15minutes the VFD shut it down!! Temps was 165°F (74°C). Ouch. I let things cool, put a fan on. Slackened off the nut by quite a bit, bu tighter han originally. When everything cooled off, ran her again for 30 minutes@ 1050rpm, temps got to 100°F (38°C) and stayed there for another 10 minutes and I stopped. Measured the endplay, with a different set-up, and its 0.00015". So I think were good.

Pretty well scared the bejeezes out of me when the VFD stopped the motor. I thought I seized the bearings! Good to know that the VFD safeguards work.

@15minutes the VFD shut it down!! Temps was 165°F (74°C). Ouch. I let things cool, put a fan on. Slackened off the nut by quite a bit, bu tighter han originally. When everything cooled off, ran her again for 30 minutes@ 1050rpm, temps got to 100°F (38°C) and stayed there for another 10 minutes and I stopped. Measured the endplay, with a different set-up, and its 0.00015". So I think were good.

Pretty well scared the bejeezes out of me when the VFD stopped the motor. I thought I seized the bearings! Good to know that the VFD safeguards work.

Attachments

Pretty odd that the vfd would know the bearing temps. Kidding, but are you sure the VFD didn't overheat? My Teco L510 will trip once in a while on a hot day after extended run time under load. I leave the door to the electrical box open a crack and its fine. I just 3d printed some fan/filter mounts for it.

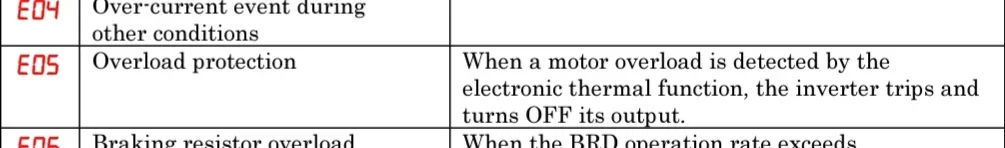

I attached the trip code description. The .3 represents when the trip occured, in this case during constant speed.Pretty odd that the vfd would know the bearing temps. Kidding, but are you sure the VFD didn't overheat? My Teco L510 will trip once in a while on a hot day after extended run time under load. I leave the door to the electrical box open a crack and its fine. I just 3d printed some fan/filter mounts for it.

Attachments

I just 3d printed some fan/filter mounts for it.

It doesn't get cooler than that!

No pun intended!