@Susquatch I’ll have to see if I can post another link to the manual.. might be easier for me to email to someone that has more experience than I do. Hahaha

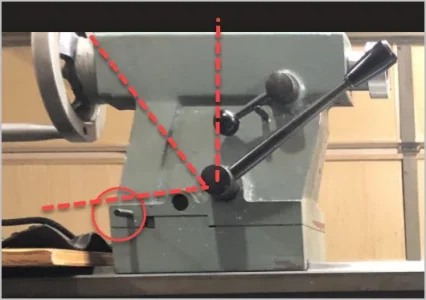

Definitely plan on including the compound eventually. I don’t have a milling machine so the compound comes off occasionally for some basic milling on the lathe.

Before I started all of this I watched pretty much all of the dropros videos... this display is really meant for a mill but it has a couple of lathe functions added like dia/rad mode and really that’s it but the milling features look pretty solid as fas as hole patterns, arcs, slopes... all looks pretty easy to use.

Reading the translated manual, I think you can mix the compound but it looks pretty confusing compared to dropros displays.

Long story short...

If and when I get a mill this display will go there and will be looking for a new display and installing a compound scale.