mechaform

Active Member

Thought I should post something in here to give a sense of what I get up to.

I've been wanting to turn some small wooden parts on my Taig metal lathe; handles, marking tool bodies, etc. Taig makes some accessories for wood turning, but I don't like them.

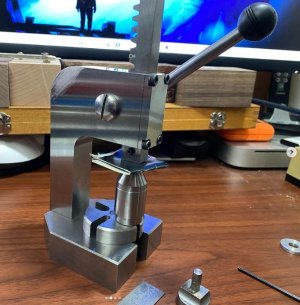

The spur centre started as 3/4" ATF steel hex stock and used the 20-hole ring of the indexing plate on my headstock, plus the Dremel toolpost I built to hold a flex-shaft handpiece with 1/8" collet. It is modelled on the "Steb" style centre instead of the more traditional cruciform pattern. The point in its middle is 1/8" O1 rod. The live centre for the tailstock has two 3/8" ID (7/8" OD) bearings press-fitted inside the cone body. The T-rest is bolted together from 3/8" O1 rod (still needs to be hardened) set into one of the last Lee Valley dovetail slides they had in the warehouse (LV used to offer the Taig lathe aimed at pen-turners).

I've been wanting to turn some small wooden parts on my Taig metal lathe; handles, marking tool bodies, etc. Taig makes some accessories for wood turning, but I don't like them.

The spur centre started as 3/4" ATF steel hex stock and used the 20-hole ring of the indexing plate on my headstock, plus the Dremel toolpost I built to hold a flex-shaft handpiece with 1/8" collet. It is modelled on the "Steb" style centre instead of the more traditional cruciform pattern. The point in its middle is 1/8" O1 rod. The live centre for the tailstock has two 3/8" ID (7/8" OD) bearings press-fitted inside the cone body. The T-rest is bolted together from 3/8" O1 rod (still needs to be hardened) set into one of the last Lee Valley dovetail slides they had in the warehouse (LV used to offer the Taig lathe aimed at pen-turners).

Attachments

Last edited: