Rauce

Ultra Member

I need to make some space in the shop and I’ve realized that since I got a knee mill I rarely use my drill press anymore and can easily live without it.

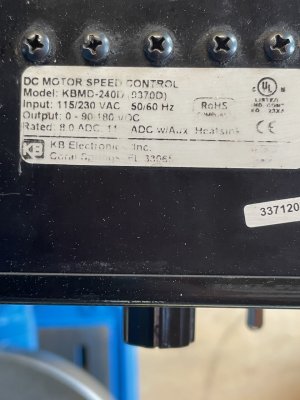

This thing is a bit cobbled together but it does work fine. The table and table arm don’t match the head so the spindle and table centers don’t match. The belt guard is missing. The step pulley diameters don’t match so belt changes are a little more tricky but honestly with the variable drive you don’t really need to ever change the belt.

The keyless chuck on it is 5/8” capacity and in like new condition. I clocked it on the spindle to minimize total runout, if I recall correctly it’s around .002-.003” with a ground pin in the chuck. Also has a digital depth gauge on it.

I feel like most of the value is in the drive/motor so I feel like $200 is a fair price but I’m open to offers. I still have most of the drill press vices in the photos so if you want one of those we could work it into the deal.

Located in Hamilton Ontario.

This thing is a bit cobbled together but it does work fine. The table and table arm don’t match the head so the spindle and table centers don’t match. The belt guard is missing. The step pulley diameters don’t match so belt changes are a little more tricky but honestly with the variable drive you don’t really need to ever change the belt.

The keyless chuck on it is 5/8” capacity and in like new condition. I clocked it on the spindle to minimize total runout, if I recall correctly it’s around .002-.003” with a ground pin in the chuck. Also has a digital depth gauge on it.

I feel like most of the value is in the drive/motor so I feel like $200 is a fair price but I’m open to offers. I still have most of the drill press vices in the photos so if you want one of those we could work it into the deal.

Located in Hamilton Ontario.

Attachments

-

C4EF5F84-5BA0-4142-A602-1C8C7A926CF8.jpeg355.3 KB · Views: 69

C4EF5F84-5BA0-4142-A602-1C8C7A926CF8.jpeg355.3 KB · Views: 69 -

728BF66C-4B40-488C-8801-C81AC709C9B1.jpeg526.2 KB · Views: 67

728BF66C-4B40-488C-8801-C81AC709C9B1.jpeg526.2 KB · Views: 67 -

40227766-AC3C-4E31-9ED4-DEA428E4892D.jpeg640 KB · Views: 59

40227766-AC3C-4E31-9ED4-DEA428E4892D.jpeg640 KB · Views: 59 -

FB5BC323-AED9-4B3B-9891-BE4A33266470.jpeg408.1 KB · Views: 61

FB5BC323-AED9-4B3B-9891-BE4A33266470.jpeg408.1 KB · Views: 61 -

1034D1C1-28E9-446C-8F94-ACC2B86A0408.jpeg385.4 KB · Views: 65

1034D1C1-28E9-446C-8F94-ACC2B86A0408.jpeg385.4 KB · Views: 65 -

800EF133-F562-4EDB-8C7A-BC0EA8002FFB.jpeg526.6 KB · Views: 72

800EF133-F562-4EDB-8C7A-BC0EA8002FFB.jpeg526.6 KB · Views: 72