jmottle

Member

Hi all,

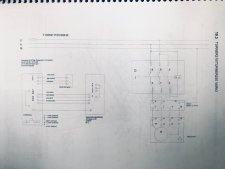

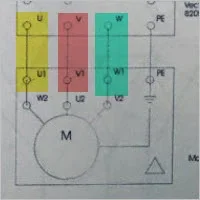

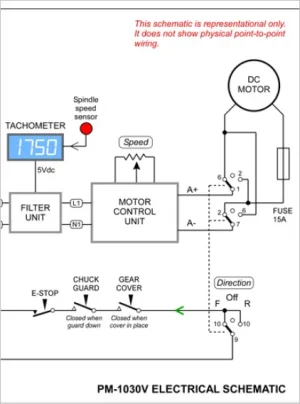

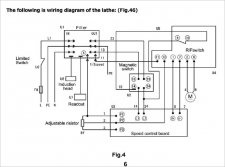

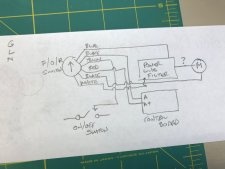

So a few years back I purchased a Chinese lathe from a dealer out in Ontario - a TopTech/Quantum 250 x 500 (equivalent 10 x 22) with an 1100W 120V motor. For the last few years I have been insanely busy running my own business so only just got back to setting up my shop. The lathe works and runs as expected, except for one thing I noticed the other day. When I was in F( forward) the chuck was spinning clockwise. If I put it to R (reverse) it runs counterclockwise, as it should for turning. Thought it was a bit weird, but being a Chinese lathe figured it was a quirk. Tonight while going over the manual I noticed something a bit concerning.

Under the power section it mentions needing three phase power. Had to research what that even was. It specifically notes that if the motor runs backwards, then you're supposed to check the phase connection order. It also says that incorrect connections will result in a hot running motor or will "not run silently and has no power". I ran it with no load at around 1200RPM for 3-4 min and the motor was still cold to touch.

So, I am unclear if the manual is just incorrect, and they shipped the North American bound units with a single phase motor, or if the motor is just not running under ideal conditions. I did notice this motor does hum quite loudly while running, more so at slower RPM. I am not sure if this is normal for this motor type or related to the motor not getting three phase.

This is in a small basement shop on a dedicated 20A circuit, but obviously I can't get three phase power to the house. I read about different converters that can be purchased but at the expense of HP. Really a bit lost here.

Just below the power connection section it also says the following, which I don't understand at all. The shop does not have a GFI breaker, assuming that's what their are talking about.

On lathes of the VARIO type (mine is this type) the frequency converter (driving regulator) might release the FI protected switch of your electrical supply. In order to avoid malfunction, you either need an FI protected switch sensitive for pulse current or AC/DC sensitive. We recommend you use an FI protected switch sensitive to AC/DC. (RCCB, type B are adequate for 1 phase and 3 phase fed frequency converters (driving regulator). An FI protected switch type AC (only for alternating current) is not appropriate for frequency converters. FI protected switches type AC are no longer used.

Help!

So a few years back I purchased a Chinese lathe from a dealer out in Ontario - a TopTech/Quantum 250 x 500 (equivalent 10 x 22) with an 1100W 120V motor. For the last few years I have been insanely busy running my own business so only just got back to setting up my shop. The lathe works and runs as expected, except for one thing I noticed the other day. When I was in F( forward) the chuck was spinning clockwise. If I put it to R (reverse) it runs counterclockwise, as it should for turning. Thought it was a bit weird, but being a Chinese lathe figured it was a quirk. Tonight while going over the manual I noticed something a bit concerning.

Under the power section it mentions needing three phase power. Had to research what that even was. It specifically notes that if the motor runs backwards, then you're supposed to check the phase connection order. It also says that incorrect connections will result in a hot running motor or will "not run silently and has no power". I ran it with no load at around 1200RPM for 3-4 min and the motor was still cold to touch.

So, I am unclear if the manual is just incorrect, and they shipped the North American bound units with a single phase motor, or if the motor is just not running under ideal conditions. I did notice this motor does hum quite loudly while running, more so at slower RPM. I am not sure if this is normal for this motor type or related to the motor not getting three phase.

This is in a small basement shop on a dedicated 20A circuit, but obviously I can't get three phase power to the house. I read about different converters that can be purchased but at the expense of HP. Really a bit lost here.

Just below the power connection section it also says the following, which I don't understand at all. The shop does not have a GFI breaker, assuming that's what their are talking about.

On lathes of the VARIO type (mine is this type) the frequency converter (driving regulator) might release the FI protected switch of your electrical supply. In order to avoid malfunction, you either need an FI protected switch sensitive for pulse current or AC/DC sensitive. We recommend you use an FI protected switch sensitive to AC/DC. (RCCB, type B are adequate for 1 phase and 3 phase fed frequency converters (driving regulator). An FI protected switch type AC (only for alternating current) is not appropriate for frequency converters. FI protected switches type AC are no longer used.

Help!