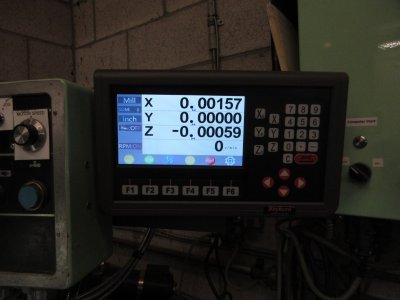

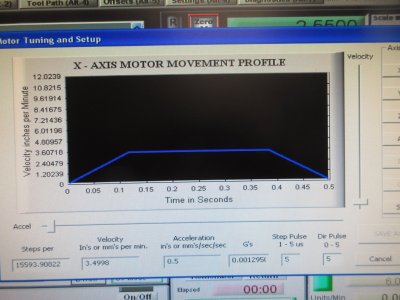

It has been 6 weeks since I had major heart surgery. Over the last 2 weeks I decided to get out into the shop and just do something. Nothing heavy but my mind needed to be worked. My birthday was in February and of course everyone wants to know what I would like for a gift so I said how about paying for a DRO for my milling machine. A few weeks latter it came in from China a Baykuni unit. Cost was about $550 with shipping and taxes. 3 axis slides and readers and display unit. A little background. In 2012 I cleaned up my milling machine and converted it to CNC with DC servo drives and motor shaft mounted Quad Encoders. The software is Mach3 running on Window's XP as it at the time was the most stable for this software. The build also included the ability to run the mill in manual mode. The X screw was worn so I purchased a custom made ball screw to replace the old worn screw on the machine from the UK. The best price was for a metric ball screw but I knew that Mach3 could be programed to get the required counts and convert metric thread to imperial motion on the X axis. At the time there was a board called a Rodgers Board that when installed with another printer port would or I say should allow the encoders to report and display each axis position without the servo's being used. That was a dismal failure and I was left with a problem on the X axis, the scales on the machine and hand wheel were imperial and the screw was metric. So without a lot of messing around the solution was to install a DRO for use in manual mode.

I started on the Y axis as it had a TEE slot for me to mount the scale. The DRO uses magnetic slides of 5um resolution. Installation was a bit trying as the tramming of the slide was to be within .006" before mounting the reader.

Tapping the mounting holes for the reader became a bit of a challenge, but cast iron is soft so I didn't break a tap.

The Y axis was the easy axis. But like I said I was in healing mode and my body could only tolerate about 2 hours in the shop each day. In my mind I thought how long can this take, well just like Elon Musk I over state and under deliver. On to the X axis. I contemplated installing this under the table and looked on the internet as some newer TOS machines came with a DRO and the Deckel FP2 & 3 had the X slide under the table, it however presented a few problems.

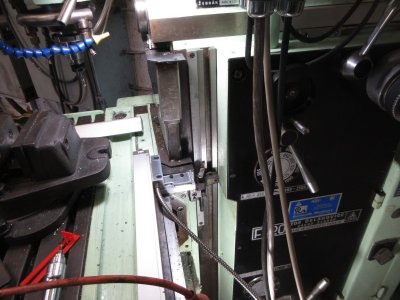

As you can see, the TOS just like the Deckel it is possible to remove the work table. The face now allows larger parts to be mounted and machined and the dividing head to be direct mounted to the T slot face of the machine. Many years ago I would do this by hand, now not a chance. I have a swing davit and a coffin hoist to do the lift, but swinging the dividing head or table into the face and I know that the slide will get hit and damaged. I decided to install the X axis slide where the X axis imperial scale was installed and removed the scale and pointer for the installation. Also the slide would not be mounted to the centre of the axis but to the right side of it. Should work? As long as I now position the reader to the right side as well.

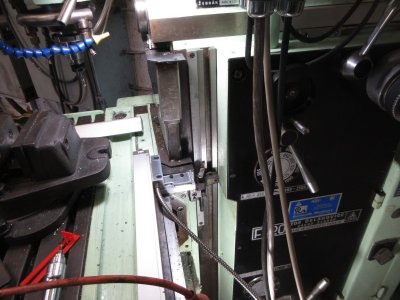

This is the X slide mounted. I had to install spacers so that the reader would clear the machine when the X axis traveled.

It looks like it will work and it is out of the way. On to mounting the reader. For this I removed the x axis scale pointer and copied it from a block of aluminum.

I can tell that this machine was hand assembled as none of the holes lined up nor were equally spaced. To make the part I needed the mill and of course threw chips everywhere I was working.

This is seat of the pants engineering. Make a little, measure a little then adjust and machine as required. I am moving forward.

The DRO kit came with brackets, that well... just were of little use. However I managed to cut the reader bracket and attach it to my adapter to mount the reader head for the X axis.

So far so good. A week has passed and each afternoon, I have to take a nap, I am gaining. Just to let you know, I don't recommend heart surgery to be on anyone's bucket list. More to come.

TonyK.

Grimsby Ontario Canada

I started on the Y axis as it had a TEE slot for me to mount the scale. The DRO uses magnetic slides of 5um resolution. Installation was a bit trying as the tramming of the slide was to be within .006" before mounting the reader.

Tapping the mounting holes for the reader became a bit of a challenge, but cast iron is soft so I didn't break a tap.

The Y axis was the easy axis. But like I said I was in healing mode and my body could only tolerate about 2 hours in the shop each day. In my mind I thought how long can this take, well just like Elon Musk I over state and under deliver. On to the X axis. I contemplated installing this under the table and looked on the internet as some newer TOS machines came with a DRO and the Deckel FP2 & 3 had the X slide under the table, it however presented a few problems.

As you can see, the TOS just like the Deckel it is possible to remove the work table. The face now allows larger parts to be mounted and machined and the dividing head to be direct mounted to the T slot face of the machine. Many years ago I would do this by hand, now not a chance. I have a swing davit and a coffin hoist to do the lift, but swinging the dividing head or table into the face and I know that the slide will get hit and damaged. I decided to install the X axis slide where the X axis imperial scale was installed and removed the scale and pointer for the installation. Also the slide would not be mounted to the centre of the axis but to the right side of it. Should work? As long as I now position the reader to the right side as well.

This is the X slide mounted. I had to install spacers so that the reader would clear the machine when the X axis traveled.

It looks like it will work and it is out of the way. On to mounting the reader. For this I removed the x axis scale pointer and copied it from a block of aluminum.

I can tell that this machine was hand assembled as none of the holes lined up nor were equally spaced. To make the part I needed the mill and of course threw chips everywhere I was working.

This is seat of the pants engineering. Make a little, measure a little then adjust and machine as required. I am moving forward.

The DRO kit came with brackets, that well... just were of little use. However I managed to cut the reader bracket and attach it to my adapter to mount the reader head for the X axis.

So far so good. A week has passed and each afternoon, I have to take a nap, I am gaining. Just to let you know, I don't recommend heart surgery to be on anyone's bucket list. More to come.

TonyK.

Grimsby Ontario Canada