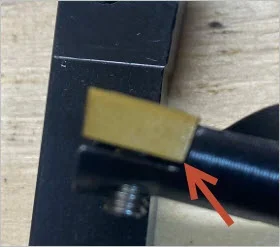

Just got my first haul off Ali Express, which included a bunch of Knockoff Korloy CCMT inserts, boring bar, and right and left turning tool holders. So far so good, the knockoff Korloy inserts work better than expected. The only piece that lacked quality is the boring bar. The insert does not seat flush in the tool holder (as pictured below). What is the best way to clean up these? Needle files, diamond stone?

I want to do this as “precisely” as possible without messing up the rake geometry.

Regardless for 50 dollars shipped I cannot complain.

I want to do this as “precisely” as possible without messing up the rake geometry.

Regardless for 50 dollars shipped I cannot complain.