TorontoBuilder

Sapientia et Doctrina Stabilitas

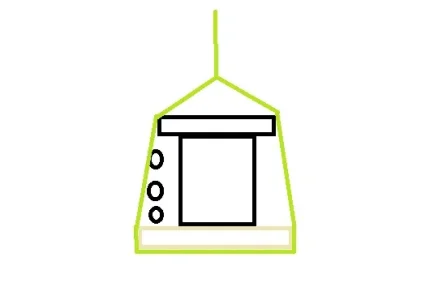

Tomorrow we move my brother's new Colchester Master 2500 lathe from its current home in Hamilton to its new home in Pickering.

Of course the factory lifting plate and eye are long gone, and I'm far less familiar with this lathe than I'd like to be... It weighs ~1800 lbs without tailstock and chuck and the headstock has so much metal that the lathe will want to be out of balance.

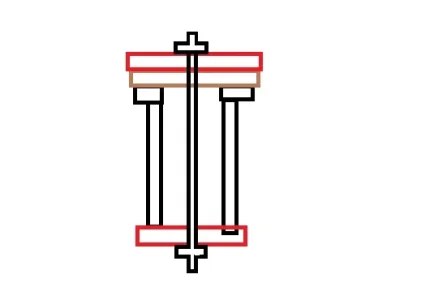

Colchester says dont sling under the bed, you risk bending the lead screw and feedshaft.

No bars or webbing thru the spindle to lift any weight by the head stock or risk screwing the bearings.

I didn't take any close up photos, but I don't recall there being any openings in the bed/web where I can run slings thru.... so I have no idea what to expect tomorrow in the way of how to pick this lathe up to get it onto a pallet and then onto a trailer. I hate winging such things.

I am now even hesitant about buying eye bolts to bolt thru the feet of the head stock to allow me to take a little of the weight up from the bottom of the head stock. I do believe that is my best second lift point though. Either thru the feet or just under the casting.

Thoughts?

Of course the factory lifting plate and eye are long gone, and I'm far less familiar with this lathe than I'd like to be... It weighs ~1800 lbs without tailstock and chuck and the headstock has so much metal that the lathe will want to be out of balance.

Colchester says dont sling under the bed, you risk bending the lead screw and feedshaft.

No bars or webbing thru the spindle to lift any weight by the head stock or risk screwing the bearings.

I didn't take any close up photos, but I don't recall there being any openings in the bed/web where I can run slings thru.... so I have no idea what to expect tomorrow in the way of how to pick this lathe up to get it onto a pallet and then onto a trailer. I hate winging such things.

I am now even hesitant about buying eye bolts to bolt thru the feet of the head stock to allow me to take a little of the weight up from the bottom of the head stock. I do believe that is my best second lift point though. Either thru the feet or just under the casting.

Thoughts?