-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you were to buy a rotary table again- would you change it’s size?

- Thread starter StevSmar

- Start date

You guys are no help, I felt sure everyone would say that 6” was more than enough…

Ok, I’ll get an 8” and then when I can’t lift it anymore I’ll fill it with helium…

Thankyou for everyone that chimed in!!! I’d thank you all personally but I’ve just spent 3 days up in the attic of our house and it’s sucked the life out of me… One day, I’ll learn to pay people to do the crappy jobs, so I have more time to plot how I’m going to lift the rotary table that’s too heavy.

Ok, I’ll get an 8” and then when I can’t lift it anymore I’ll fill it with helium…

Thankyou for everyone that chimed in!!! I’d thank you all personally but I’ve just spent 3 days up in the attic of our house and it’s sucked the life out of me… One day, I’ll learn to pay people to do the crappy jobs, so I have more time to plot how I’m going to lift the rotary table that’s too heavy.

so I have more time to plot how I’m going to lift the rotary table that’s too heavy.

Just get a rolling cart and build a wooden (or welded) platform the same height as your mill table and just slide it on or off. It's even easier if you have a mill table height that is adjustable or a lift on your cart cuz then you can always slide down. If the cart is big enough you can also put dividing heads and the like on it.

Sadly, my workshop isn’t big enough for that…Just get a rolling cart

My current thought for the future is to put a cabinet above the lathe and mill that has electric winches inside- to winch up each heavy thing into it’s cubby hole…

winch up each heavy thing into it’s cubby hole…

Sounds like a nice solution. Just make sure they can't fall. That would NOT BE GOOD!

Sadly, my workshop isn’t big enough for that…

Nice thing about carts is that they can be rolled anywhere - preferably not outside.....

When you purchase your RT be sure to get the indexing kit that goes with the RT. The after market kits leave a lot to be desired.....

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

This is my 6" HV RT Dividing Plate Rant.......

So, I acquired a 6" HV RT which is basically this one sans TS and dividing plates. https://www.busybeetools.com/products/rotary-table-6in-c-w-tail-stock-indexing.html Then I order a dividing plate kit from Amazon...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

It’s amazing how fast even that size becomes too small! I have one OE Bridgeport of that size and had to McGyver setups in the past because it was too small…I bought a used 12" News *(Yuasa) close to 30 years ago, wouldn't want it any smaller. A plate on top is a good idea to extend it, but more cost, time to make and futzing about when you go to use it.

Remember: you can always put a small part on a large RT; but a large part does not work on a small RT.

When you get your RT get one that lets you mount it 90 degrees. and think about a chuck for it. I have an 8". It's heavy enough!You guys are no help, I felt sure everyone would say that 6” was more than enough…

Ok, I’ll get an 8” and then when I can’t lift it anymore I’ll fill it with helium…

Thankyou for everyone that chimed in!!! I’d thank you all personally but I’ve just spent 3 days up in the attic of our house and it’s sucked the life out of me… One day, I’ll learn to pay people to do the crappy jobs, so I have more time to plot how I’m going to lift the rotary table that’s too heavy.

What were you doing in the attic Steve? Air sealing by chance? How did it go?

I have a 6" import horizontal/vertical with dividing plates and a 12" Yuasa horizontal only with dividing plates and an excellent vernier dial setup. I'm going to sell the 6" and buy a 8 or 10" H&V table. That would suit 90% of my needs. I will keep the 12" though. Its sooo nice...

Yeah, I have a six inch Emco, a gift from a now passed friend, and it suits me well enough for now, but my mill (Centec 2A) uses MT-2, for it's spindle taper, and 6 inches is gonna about max out the room on the table. It's a BIG R/T, for the size of table it is on!

Gotta admit, that rather than mounting the table on it's edge, I would really like to find a well made, universal dividing head, that was of a scale to suit that mill! IIRC, Hardinge made one nearly perfect, but the few of those I have seen change hands, did so at prices that were eye watering, to say the least! IIRC, Ellis made some that were almost as small, though not as refined.

Gotta admit, that rather than mounting the table on it's edge, I would really like to find a well made, universal dividing head, that was of a scale to suit that mill! IIRC, Hardinge made one nearly perfect, but the few of those I have seen change hands, did so at prices that were eye watering, to say the least! IIRC, Ellis made some that were almost as small, though not as refined.

I have an 8 Inch Vertex I bought at House of Tools years ago. It has a 6 inch chuck so is about all I care to lift. As I get each year older it gets pounds heavier. My mill table is 35 inches so for that reason I wouldn't want it any bigger. At some point I will build a rolling stand that will hold my 2 vises and the RT so I can just slide them on and off the table. A small RT or a Spin Indexer would be mighty convenient for small jobs. I could just grab it in the vise and use it that way without mounting the RT.Eventually… I’ll get a rotary table for my mill.

I like the 8”, but thinking of 15 years from now I may not appreciate the +60lb weight of it…

Today, I can’t imagine needing a rotary table bigger than 6” (probably even 4”) which has led to the question of this post: If you were to buy a rotary table again- would you change it’s size?

My wife wanted some soffit pot lights and while the electrician was doing that we got some soffit receptacles for Christmas lights, and while that was being done I decided to run the cables for some security cameras and put a couple of 1.5” conduits from the attic to the basement.What were you doing in the attic Steve? Air sealing by chance? How did it go?

And not being the crispest chip in the bag I volunteered to do most of the work in the attic… I did let the electrician drill through the top plate and through a cable though. All fixed now, except for drywalling where I had to cut open the wall…

I’d rather be struggling to lift an 8” rotary table than ventilating my scalp with roofing nails.

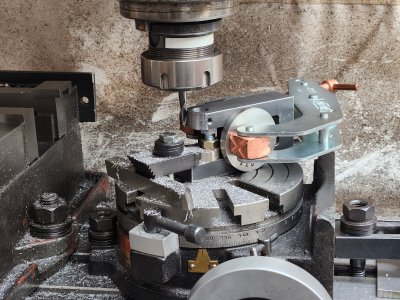

I just discovered a video I have of my 8" RT. Here is me making a hole for a trailer leveler jack repair. You can see the part isn't that big yet the work holding is still barely able to manage.

Last edited:

I see what you mean about hardly any headroom!You can see the part isn't that big yet the work holding is still barely able to manage.

You can see the part isn't that big yet the work holding is still barely able to manage.

Why didn't you chuck it in the four jaw on your lathe?

Because the RT was new and I needed to try it!Why didn't you chuck it in the four jaw on your lathe?

This is a 6" that I bought many years ago just to mount a 3-jaw chuck to do dividing work with it in the vertical position. Perfectly suited for that purpose, but for actual RT work, it's way to small. I'd like to get a 10" one of these days, and maybe mount a 12"-14" plate on top when required.