-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi heat cement

- Thread starter JuanH

- Start date

George

Member

I’ve decommissioned my homemade propane foundry, and have acquired a 50ltr stainless steel beer keg, I’ve noted the ITC100, and now for the wool? Best place please, Amazon? Also do i need to coat it in refractory cement? Or can it be just the wool with a ITC coating? LOL my propane foundry was a playsand plaster of Paris construction, it worked but brakes down after a cpl of years and it was bloody heavy

Any info would be appreciated.

Thanx in advance.

Any info would be appreciated.

Thanx in advance.

Tom O

Ultra Member

A beer keg works great I used 2 wraps of kaowool painted with ITC I used sodium silicate to glue it in place.

( it’s cheap and can be used for any core making ) For the bottom I used fireclay/sand that cracked as it dried out so I leveled it with sand and used a round shelf for a kiln that works well. I use a blower on mine with a regulator for propane and have had no problem with brass, I still have to try cast iron. I got my components from Ceramics Canada.

Tongs for #6 clay graphite crucible.

Tongs for 6x6” steel tubing with a bolt at each corner the nut is radiused to fit. They work quite well because lifting on the bottom naturally pulls them together giving you freedom to use the other hand to control the pour.

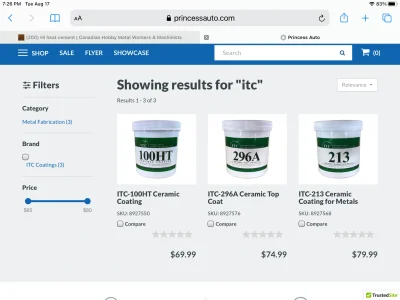

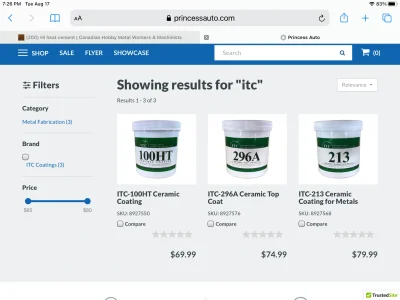

Here are the Princess Auto prices I’ve only used the ITC100 so far I’d like to try some of the coating stuff ( skimming ) for higher temps but I haven’t had the need yet.

( it’s cheap and can be used for any core making ) For the bottom I used fireclay/sand that cracked as it dried out so I leveled it with sand and used a round shelf for a kiln that works well. I use a blower on mine with a regulator for propane and have had no problem with brass, I still have to try cast iron. I got my components from Ceramics Canada.

Tongs for #6 clay graphite crucible.

Tongs for 6x6” steel tubing with a bolt at each corner the nut is radiused to fit. They work quite well because lifting on the bottom naturally pulls them together giving you freedom to use the other hand to control the pour.

Here are the Princess Auto prices I’ve only used the ITC100 so far I’d like to try some of the coating stuff ( skimming ) for higher temps but I haven’t had the need yet.

George

Member

@Proxule thats interesting could you tell me/ the pundits the formula please, also I picked up a nice bit of aluminum to smelt next spring, need to go buy a few blades for my reciprocating saw now lol 22.5 inch wheel off a semi, has a cracked rim friend works for a truck repair shop

Attachments

Proxule

Ultra Member

Nice rim!

Here is the videos and information on water glass, You will need carbon dioxide gas to harden the water glass, I suppose an open flame will do it too, Never tried.

https://www.instructables.com/How-to-Make-Sodium-Silicate-Water-Glass/

Here is the videos and information on water glass, You will need carbon dioxide gas to harden the water glass, I suppose an open flame will do it too, Never tried.

https://www.instructables.com/How-to-Make-Sodium-Silicate-Water-Glass/

Tom O

Ultra Member

When I made the furnace I just coated the inside of the keg to hold the kaowool in place this doesn’t require any c02 to harden it. When you are ready for more complex castings using cores you will need c02 to harden them unless you go the route of Myfordboy who adds resin to make his cores with good success .

The books I read on it said you could use the co2/argon gas from a mig welder to harden it.

With a 3d printer it should be fairly easy to print core boxes with venting holes and a hose barb

I bought a gallon of the liquid silicate but have not ventured into cores yes

Sent from my iPhone using Tapatalk

With a 3d printer it should be fairly easy to print core boxes with venting holes and a hose barb

I bought a gallon of the liquid silicate but have not ventured into cores yes

Sent from my iPhone using Tapatalk

Similar to the one by artful bodger. I bought his book and am collecting parts

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I would think so

For 10-30 dollars I would try it

Sent from my iPhone using Tapatalk

For 10-30 dollars I would try it

Sent from my iPhone using Tapatalk