Tomc938

Ultra Member

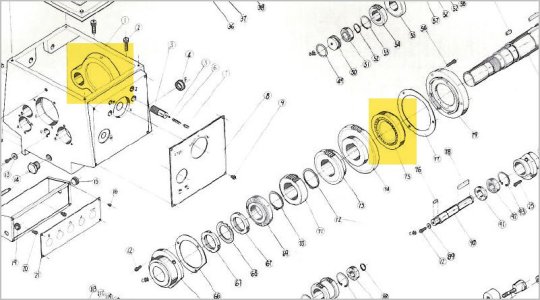

I got the new bearings and races for my 1440 rebuild today. Pretty excited as I can now start the headstock assembly.

Anyone have suggestions for getting the old races out?

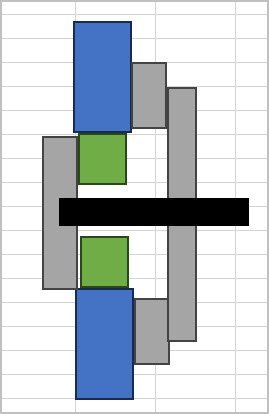

And how about the new ones in? I'm thinking threaded rod and a couple of plates and the old races to pull the new ones in.

Any suggestions would be appreciated.

Anyone have suggestions for getting the old races out?

And how about the new ones in? I'm thinking threaded rod and a couple of plates and the old races to pull the new ones in.

Any suggestions would be appreciated.