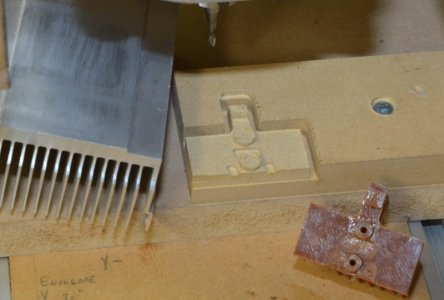

The CNC shop that used to make my heat sink has closed down. I think I've mentioned that before. He's kept a HAAS and some other equipment for playing with motorcycles. After whining and snivelling and supply some extra raw material he made 40 of them for me. Got to watch some of them being made. Very educational.

When I picked them up he also gave me the Niagara 3 flute 1/8" end mill he used to make the fins along with a lesson on how he did the chamfering on the fin edges. A shame to see all the knowledge retire.

He also gave me a zip drive with the top and bottom machining information in the form of two VNC files. The first part is text but the rest is binary. Is there a way to turn these files into G-Code or are they HAAS only?

I'm off to Vancouver tomorrow to have them anodized.

When I picked them up he also gave me the Niagara 3 flute 1/8" end mill he used to make the fins along with a lesson on how he did the chamfering on the fin edges. A shame to see all the knowledge retire.

He also gave me a zip drive with the top and bottom machining information in the form of two VNC files. The first part is text but the rest is binary. Is there a way to turn these files into G-Code or are they HAAS only?

I'm off to Vancouver tomorrow to have them anodized.