gerritv

Gerrit

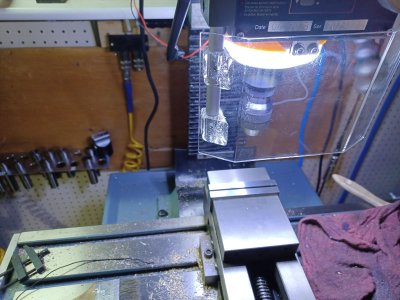

When the idea of a Deckel FP1 in my basement fell through last Dec, I instead ordered a new KC20 from KBC tools. Picked it up in my baby trailer and with help from one of our members got it into the basement in one piece.

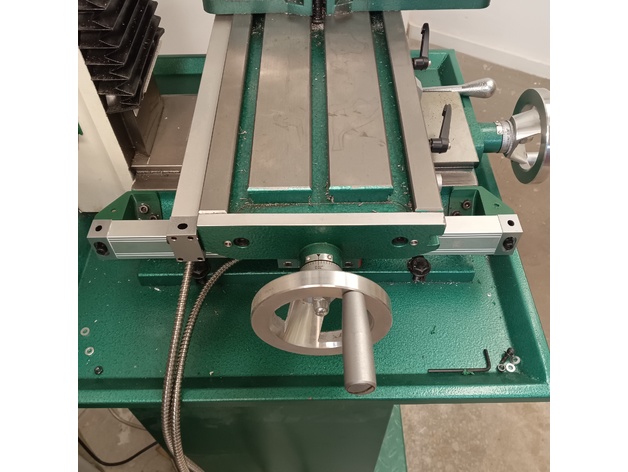

First issue was a lot of resonance when cutting, esp. in steel. The solution: Sandwhich 1/2" mdf between the chip tray and cabinet. And support the base on 4 adjustable rubber pads. I used 1/2"x2" hot rolled flat bar because I have lots of it.

First issue was a lot of resonance when cutting, esp. in steel. The solution: Sandwhich 1/2" mdf between the chip tray and cabinet. And support the base on 4 adjustable rubber pads. I used 1/2"x2" hot rolled flat bar because I have lots of it.