Jswain

Joe

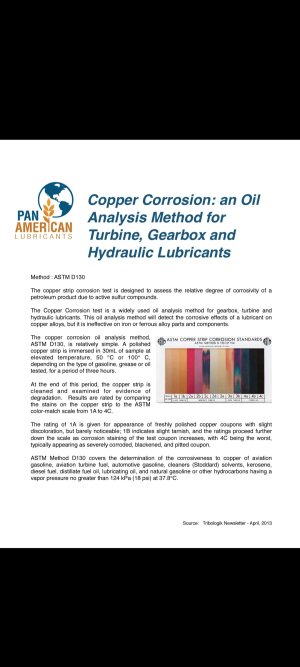

The thing to look for if you're worried about it being yellow metal safe is the copper corrosion test results of the gear oil you plan to use.So what is an ideal oil for this application?

I'm afraid to open the gear box, I half expect to see liquid gold again. This is what I used.

1a being very little discoloring and 1b being slightly more but still very little discoloring, anything else do not use.

Copper Strip Tarnish Test: 10 Gear & Trans Fluids

The Copper Strip Tarnish Test (ASTM D130-10) is a standard test of a lubricant to indicate how corrosive it is to copper alloys that may be in a transmission. My restored 1989 Suzuki Sidekick has brass synchromesh transmission components that may be vulnerable to additives found in many GL5...

bobistheoilguy.com

I was slightly worried when I filled my RF45 with Amsoil long life 75w90 as I believe it was 1b, so I emailed amsoil and they said it was 100% safe on yellow metal.

Attachments

Last edited: