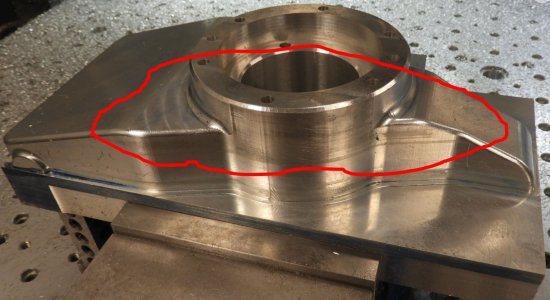

Looks nice. About how long to mill a part like your picture?

I don't quite get the requirement of the vise & 123 blocks. Could you not fixture locate & clamp directly on the tooling plate? Do you have much experience with MiteeBite / cam lock systems? I have 2 cnc buddies, one loves them, the other hates them. Maybe they do different kinds of work, I didn't get a chance to ask about details.

I don't quite get the requirement of the vise & 123 blocks. Could you not fixture locate & clamp directly on the tooling plate? Do you have much experience with MiteeBite / cam lock systems? I have 2 cnc buddies, one loves them, the other hates them. Maybe they do different kinds of work, I didn't get a chance to ask about details.